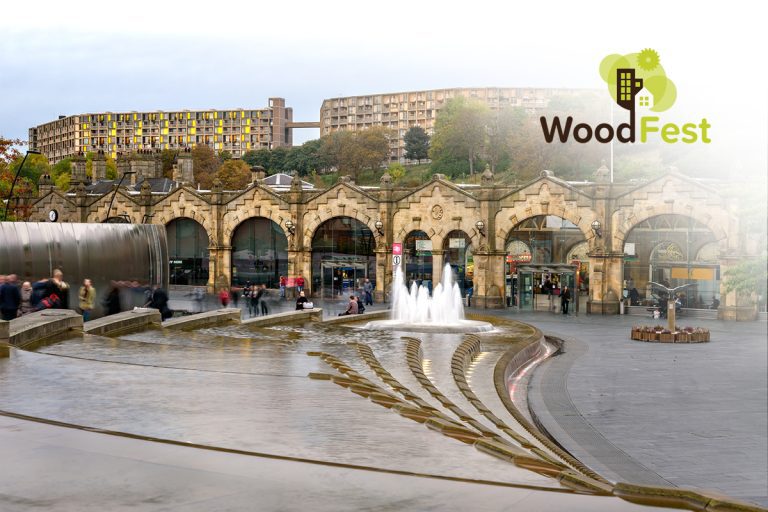

WoodFest comes to Sheffield in February with a focus on health and wellbeing, low carbon, circular economy, building performance, offsite construction and modular design. The month-long event will feature wood in design and construction throughout Sheffield and Yorkshire. The programme includes an exciting line-up of events, seminars, exhibitions and challenges celebrating the versatility and sustainability of building with wood, organised by the UK timber industry’s campaign, Wood for Good. Christiane Lellig, Wood for Good campaign director, said: “WoodFest Sheffield promises to offer a fantastic opportunity to bring all those involved with the built environment to explore what can be achieved when we work together.” “Each event is a chance to learn and share about the use of timber in architecture, particularly around health and wellbeing and offsite construction. It provides a platform to discover what’s happening in the region and to be inspired by timber design.” WoodFest kicks off on 7 February with Small Project / Big Challenge, an evening seminar with sustainability-focused Sheffield architects Paul Testa Architecture and Jon Carr Structural Design along with Sheffield University. They will discuss design and structural challenges with examples including the multi-award-winning Hen House. On 8 and 9 February TRADA will run its annual student challenge at Sheffield University for students of engineering, architecture, architectural technology, quantity surveying and landscape architecture. Judged by high profile engineers, architects and quantity surveyors, multi-disciplinary teams will compete in an intense 48-hour challenge to design an exemplary student accommodation predominantly from timber. On 21 February, Sheffield-based consultancy, Ollio, and experts from the Kollider projects will host a healthy building evening seminar along with a networking and drinks reception. A tour of timber door, window and stair manufacturer JELD-WEN’s production facilities will take place at 10am on 28 February. This will offer the chance to see first-hand how timber doors are made in the company’s Sheffield factory, from the timber arriving on-site through to the finished product leaving for distribution. The tour will include a presentation followed by a drinks reception for all attendees. Managing forests in a sustainable way is vital to protect these important ecosystems, reduce the impact of climate change and to preserve plant and animal species for the future. On 28 February, the PEFC (the Programme for the Endorsement of Forest Certification) will deliver a lunchtime CPD to explain how to procure sustainable timber and timber from sustainably managed forests. Further events include window-specialist Bereco hosting a CPD session on noise and health in the build environment at their Sheffield showroom. There will be a behind-the-scenes tour with Sheffield timber merchant Arnold Laver including a networking lunch, followed by an afternoon CPD. Visitors will have the opportunity to see their production facilities including roof truss manufacturing and its treatment plant. Striking examples of great architecture and design, such as the Hunt House – featured in The Modern Timber House in the UK book, will offer visits focussed on sustainability and wellbeing within the Sheffield region. This will be followed by an exhibition and further evening event on offsite construction and modular design at The Arts Tower. Keep checking the WoodFest Sheffield web page to book your place, find out more details, confirm dates and see further added events. Partners include: Arnold Laver; Bereco; Constructing Excellence Yorkshire & Humber; Halliday Clark Architects; IstructE; JELD-WEN; Paul Testa Architecture; PEFC UK; Sheffield University and TRADA. Book your place for any of the WoodFest Sheffield events here. www.woodforgood.com