Aggregate Industries, the leading construction material supplier, has proved its unrivalled credentials once again in its recent work at the ground-breaking Woodsmith Mine development in North Yorkshire. The £2 billion development will constitute one of Britain’s biggest mines; to incorporate a vast mine head at Woodsmith Mine, Sneaton, with shafts 4,921ft (1,500m) deep, and a 23-mile underground tunnel to transport the potash to Wilton International near Redcar.

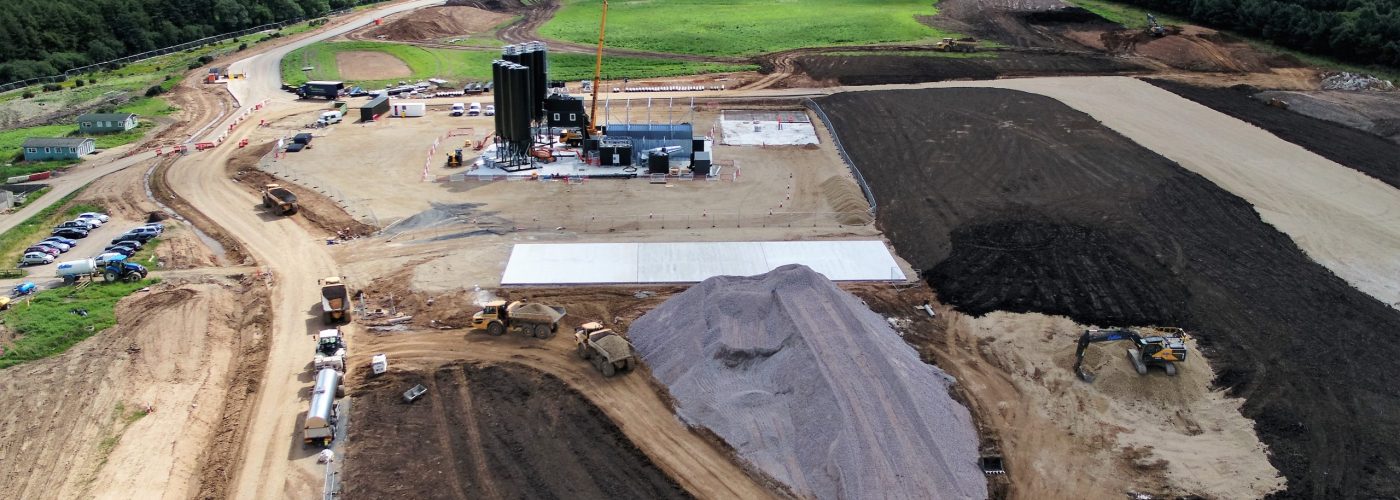

The project needed the supply and delivery of a vast high quality, hardstone aggregate that was to be used for road construction and ground stabilisation works; therefore the contractor Collins Earthworks called for the services of Aggregate Industries.

“Having worked on numerous projects of this size, we were able to apply our learnings to ensure an even more robust approach to the aggregate supply. From working closely with Collins Earthworks at the inventory stages, we have put a stringent plan in place to ensure a continuity of supply without disruption, ensuring the teams have the exact specific technical and quality specification of aggregate as and when they need it,” said John Taylor, sales manager, Aggregates North.

During the period of May to December 2017, Aggregate Industries’ specialist team has supplied 81,000 tonnes of Type 3 sub-base aggregates and 9,000 tonnes of Type 1 sub-base aggregates, constituting a total of 90,000 tonnes. A further 20,000 tonnes of material was provided during January and February 2018.

In order to effectively and sustainably manage the scale of supply demands, material has been sourced from the business’ Glensanda quarry and shipped to the nearby Teesside port, before being road hauled direct to the project. This approach has enabled the team to deliver in excess of 500 tonnes per day, while operating a stringent quality procedure to ensure the material exceeded the structure and strength values required for the project.

“I would like pass on my thanks to Aggregate Industries for providing such a swift and efficient approach to our aggregate requirement which has been vital to keeping the project on schedule. Working on a project of this calibre and scale, it is vital to partner with genuine experts with not just the product capabilities but the expertise behind it, and the team haven’t failed to deliver. I’m sure this relationship will continue as we progress the project over the next four years,” commented on the project Dave Shaw, site manager at Collins Earthworks.