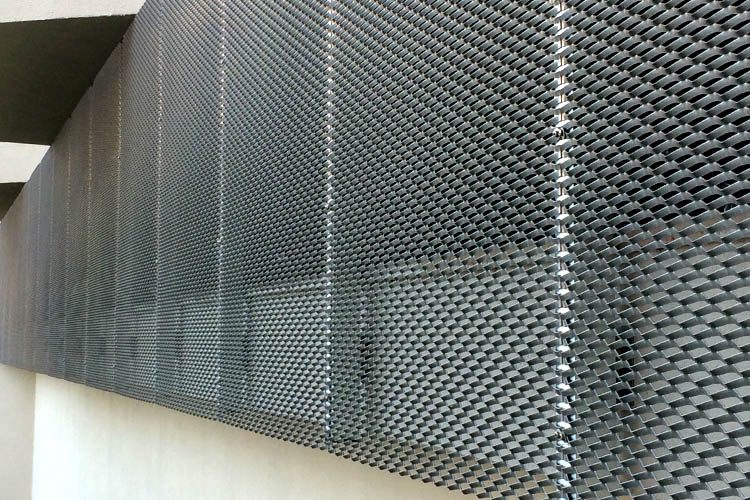

Architectural design has evolved significantly over the years, with a greater emphasis on both aesthetics and functionality. One material that has gained popularity for building facades is perforated metal panels. These panels are not only visually striking but also provide practical benefits that enhance the durability and performance of modern structures. Available in various metals such as aluminium and steel, they are widely used in commercial, industrial, and even residential projects. Strength and Longevity in Construction One of the key advantages of perforated metal panels is their durability. Made from robust materials like aluminium, copper, and stainless steel sheet, these panels are designed to withstand harsh weather conditions, including heavy rain, strong winds, and intense sunlight. Unlike traditional cladding materials such as wood or concrete, metal panels do not warp, crack, or degrade over time. Stainless steel, in particular, is known for its corrosion resistance, making it a preferred choice for projects in coastal or high-humidity environments. When used as part of a building’s exterior, a stainless steel sheet offers long-term protection against rust and deterioration, reducing maintenance costs while preserving the structure’s integrity. Energy Efficiency and Sustainability Beyond strength, perforated metal panels contribute to energy efficiency by improving ventilation and controlling solar heat gain. Buildings with solid facades can trap heat, increasing reliance on air conditioning. Perforated panels allow air to circulate while providing shade, helping to regulate indoor temperatures and reduce energy consumption. The sustainability of these panels is another major advantage. Many perforated metal panels are made from recycled materials, and metals like stainless steel and aluminium can be recycled at the end of their lifespan. This makes them an environmentally responsible choice for architects and builders looking to reduce a project’s carbon footprint. Aesthetic Appeal and Design Versatility Perforated metal panels offer endless possibilities in architectural design. With the ability to create custom patterns, shapes, and textures, they allow designers to bring creativity into building facades. Whether used to form intricate geometric designs, corporate branding, or artistic expressions, these panels provide a unique visual identity to any structure. A stainless steel sheet with a perforated pattern can be finished in various ways, including polishing, powder coating, or anodising, to achieve different aesthetic effects. Matte, glossy, or coloured finishes can be applied to match a building’s overall design theme. The versatility of these panels makes them suitable for both modern and traditional architectural styles. Noise Reduction and Acoustic Benefits In urban environments, noise pollution can be a major concern. Perforated metal panels can be designed to act as sound barriers, helping to absorb and deflect noise from traffic, construction sites, or nearby commercial activities. When combined with acoustic insulation materials, these panels can significantly reduce noise levels within a building, creating a quieter and more comfortable environment for occupants. Public buildings, offices, and residential complexes located in high-traffic areas can benefit from the sound-dampening properties of these panels. Whether installed on exterior facades or as interior partitions, they contribute to improved acoustic performance without compromising on style. Protection and Security Another functional advantage of perforated metal panels is the added layer of security they provide. While they allow for ventilation and visibility, their sturdy construction makes them difficult to penetrate, acting as a protective barrier against vandalism and unauthorised entry. For commercial and industrial buildings, a stainless steel sheet with perforations can be used for fencing, window coverings, or parking structures, enhancing security while maintaining airflow and natural light penetration. These panels are also used in public infrastructure projects, such as bus shelters and train stations, where durability and safety are key considerations. Low Maintenance and Cost-Effectiveness Perforated metal panels require minimal upkeep compared to other facade materials. Unlike wood, which needs regular sealing, or concrete, which can develop cracks, metal panels are resistant to environmental wear and tear. Stainless steel and aluminium, in particular, require only occasional cleaning to maintain their appearance and functionality. The long lifespan of these panels translates to cost savings over time. Reduced maintenance, energy efficiency, and durability make them a smart investment for property owners looking to minimise long-term expenses while enhancing the value of their buildings. A Practical and Stylish Choice for Modern Architecture Perforated metal panels offer a rare combination of strength, style, and sustainability. Their ability to enhance durability, improve energy efficiency, and provide design flexibility makes them a valuable addition to contemporary buildings. Whether used for large commercial developments or residential projects, these panels serve both functional and aesthetic purposes, ensuring that structures remain visually appealing and structurally sound for years to come. With materials like stainless steel sheet leading the way in longevity and performance, perforated metal panels are set to remain a top choice for architects and builders looking to balance innovation with practicality.