TECHNOLOGY is having an ever-greater impact on the construction sector. Many ideas that were once thought of as gimmicks – or even the stuff of science-fiction – are now being steadily incorporated into the mainstream industry, with new and practical applications for technology being developed at a rapid pace.

Here we’ve shortlisted the 8 construction technology trends to keep your eyes on in 2018.

AUTONOMOUS VEHICLES

With a drive to improve efficiency and safety on construction sites, autonomous vehicles are gaining traction and could be seen on some projects in 2018.

Just as driverless cars promise to revolutionise the way in which we travel, autonomous vehicles could transform our building site environments – helping to address a shortage of skilled labour and enhancing productivity.

Above: Autonomous vehicles could transform construction sites and address shortages of skilled labour (image courtesy of Built Robotics)

Several developers have already created prototypes of autonomous construction vehicles ranging from bulldozers and tractors, to cranes and excavators.

While entry costs and regulations remain serious barriers to adoption, several observers believe that we may see self-driving vehicles on construction sites before we see them on roads – particularly as sites are highly controlled environments.

VIRTUAL + AUGMENTED REALITY

Next up is a technology area that has been on construction’s radar for several years, and indeed made it onto our 2017 tech roundup; virtual and augmented reality.

These visual technologies continue to be “one to watch” in 2018 as they gain greater traction within the construction industry and become valuable tools for project teams and end users alike.

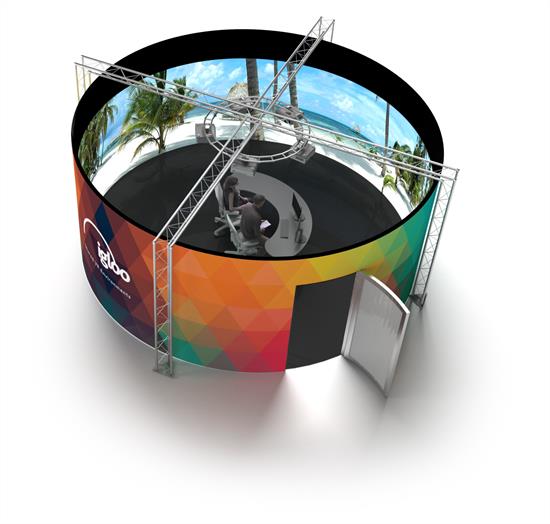

Above: Enveloping 360 pop-up tents or rooms allow designers to step inside their buildings (image courtesy of Igloo Vision)

Virtual Reality – or VR – creates an immersive environment in a headset or cardboard viewer, or even an enveloping 360 pop-up tent or room – enabling contractors, designers and end users to step into their buildings in the future – either during key stages of construction, or in their completed states.

Prominent examples of this in practice include London’s 22 Bishopsgate skyscraper and the impressive “Tomorrowland” at the Shanghai Disney Resort.

Augmented Reality – or AR – is also finding its feet, providing a graphic layer to our real-world view and offering a wide array of data to site personnel – from design information and specifications, to statistics on productivity and health and safety warnings.

Whilst VR and AR have long been touted for their future potential, they are now being used in anger and are set to drive clear benefits for project teams in 2018.

EXOSKELETONS

Exoskeletons are a technology that has been long-touted for its potential to make construction more efficient. Like many of the technologies on this list, they might sound more like the stuff of science fiction, than a credible real-world application. However, the wearable mechanical suits – that are worn outside clothing to help with lifting heavy equipment, machinery, or supplies – are now becoming a reality.

Above: Exoskeletons have been specifically developed for the construction industry (image courtesy of Lockheed Martin).

Designed to “augment with humans” and help them overcome physical weaknesses, these suits could aid construction workers with everyday mundane, repetitive tasks, supporting better physical health and helping to combat conditions such as arthritis and hand-arm vibration.

Around 40 companies are now manufacturing exoskeletons worldwide, so you may well see them on a site near you in 2018.

ADVANCED MATERIALS

The world of construction materials is advancing at an incredible rate as new technologies enter the construction sector, enabling further research and development.

In the last 12 months we’ve reported on many innovations including “Self-healing concrete” – which contains calcite-precipitating bacteria which germinate when water enters the cracks in decaying concrete, filling the emerging air gaps.

We have also seen “Kinetic paving” which harvests energy from the footsteps of pedestrians to generate electricity, “4D-printed structures” that have the ability to re-shape or self-assemble over time by virtue of how they are formed and how different elements of their composition respond in differing conditions and “smog-eating buildings” coated in photocatalytic titanium dioxide that reacts with light to neutralise pollutants in the air of the some of the world’s most congested cities.

UAVs

Above: Drones are becoming widely used in the construction industry (image courtesy of Aibotix).

The rise of unmanned aerial vehicles (UAVs) in the construction industry – often referred to as drones – was featured on our 2017 list and is set to significantly pick-up pace in 2018.

UAVs are now being used for health and safety inspections, progress reporting and most-prominently in site surveying; capturing accurate data on large areas of land in just a few minutes and accessing potentially hazardous zones with ease, keeping surveyors themselves save.

While there has been much publicity about the potential for drones to carry out deliveries, it is the construction industry that is predicted to be the biggest user of commercial drones in the coming years.

“The construction industry is predicted to be the biggest user of commercial drones in the coming years”

Regulation of UAVs remains a hot-topic, particularly as the rate of technology advancement often pulls ahead of legislation and its enforcement. Falling entry costs and the availability of UAVs to a mass market has only served to compound this issue.

ROBOTICS

The successful application of robotics in the construction sector could enhance efficiency, productivity and safety in many instances, making it a highly-attractive prize for those that see its value.

Above: An “in-situ fabricator” developed at the National Centre of Competence in Research (NCCR) Digital Fabrication in Zurich ( image courtesy of NCCR Digital Fabrication).

The last 12 months has seen further iterations of brick and track-laying robots and even a machine capable of tying rebar unveiled – the latter being part of a series of in-situ fabricators.

The challenge for this area again remains the entry-cost and its credibility. Many struggle to recognise and accept the application of robots, seeing the concept as science fiction.

3D PRINTING

Above: 3D printing of full-scale houses is now possible (image courtesy of Apis Cor).

The use of 3D printing technology to produce physical objects has advanced significantly in construction over the last 12 months – at all levels of scale.

Accurate digital design information allows 3D printing to be used for everything from rapid prototyping, component manufacture and scale modelling, to full scale printing of house and bridge components. The technology is even being considered as part of serious and steadily advancing proposals by scientists to build a human habitation on Mars in the next 100 years

INTERNET OF THINGS

We end with a technology that may have the power to change the industry more than any other; the Internet of Things.

Put briefly, the Internet of Things (or IoT) is a network of physical devices that are embedded with sensors and network connectivity to allow those objects to connect and exchange data. The data received is collated and analysed to inform future decisions.

In construction, the Internet of Things is being used in many ways such as remote operation and monitoring, supply replenishment, construction tool tracking and in equipment servicing and repair.

The key prize for the construction sector is “big data” – the ability to hone and perfect the built environment that we construct and operate by having an aggregate, trend-level view of how it is performing. Such data can be obtained from building management systems or sensor nodes integrated within built assets.

In the future, the Internet of Things could impact how we construct all buildings and infrastructure leading to more efficient and responsive cities and an improved built environment, impacting everyone’s quality of life and the development of our societies.

*ARTICLE Credited to The B1M*

Images courtesy of NCCR Digital Fabrication, Built Robotics, Rio Tinto, Grendelkhan, Komatsu, Igloo Vision, Daqri, Lockheed Martin, Suit X, Ekso, Nemesi, Pavegen, Self-Assembly Lab, MIT, Stratasys, Autodesk, Elegant Embellishments, 3D Robotics, Leica Geosystems, Aibotix, Apis Cor, DUS Architects, SOM, Foster + Partners, Volvo Construction Equipment and Business Wire.