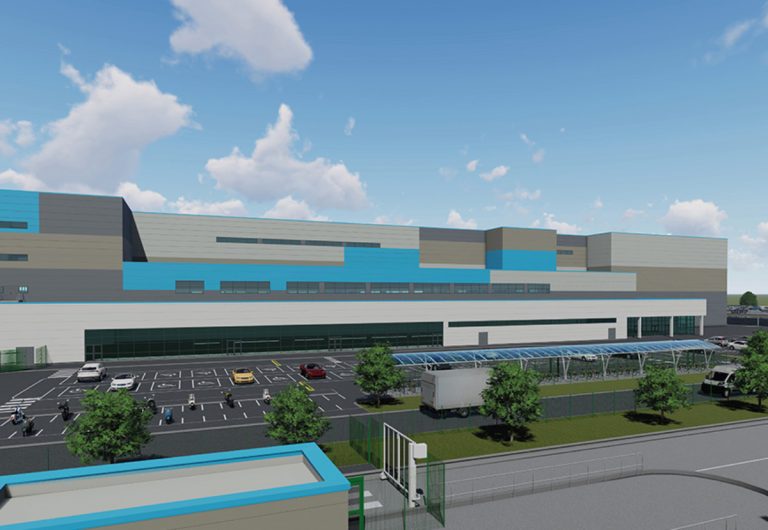

As the next step in the integration of Vodafone Hungary and UPC, in the autumn of 2022, colleagues working in the company’s Budapest offices will move to the Budapest ONE office park. The complex, developed by Futureal, will house Vodafone’s new headquarters, which will offer innovative technological solutions with the highest standards, focusing not only on sustainability but also on the health and well-being of employees. Vodafone announced the acquisition of UPC Hungary last August, followed by the legal merger of the two companies on April 1, 2020. The next stop of the merger will directly affect the company’s employees, as, from October 2022, colleagues working in the Budapest headquarters will move to a common building in the Budapest ONE office park. “Vodafone Hungary has always stood for flexible working, however, with our recent experience in mind, we are trying to redefine and further advance this flexibility in terms of both office work and remote working. Of course, we will continue to provide our colleagues the possibility to work from home, as this is justified not only by the needs of our employees but also by considerations of environmental awareness. At the same time, we consider it important to create a green, digital office environment for our employees that inspires them and also supports their mental and physical well-being. In addition to the innovation aspects, we were looking for a modern building where we will be able to showcase our latest, most innovative technologies. In the coming months, we will be working with our colleagues and partners to create an office space that’s most suited to the needs of future employment.” – said Amanda Nelson, CEO of Vodafone Hungary. Vodafone aims to use technology to build a better, more sustainable future and protect the planet through environmentally conscious operation. Accordingly, the company considers it important to be able to showcase to visitors the various technological innovations offered by Vodafone and the tools used for implementing green guidelines, in a showroom to be set up in the new building. The Budapest ONE office park, designed in compliance with the standards of the environmentally conscious WELL Building and BREEAM building certification systems, is fully in line with Vodafone’s efforts to this end. The office building will be equipped with an energy-saving, intelligent central building management system, and electric car chargers will also be available in the parking garage. In the building, the mental and physical wellbeing of employees will be supported, among others, by a multifunctional community room, a bicycle storage area with a shower, a panoramic running track at the top of the building and a half-hectare open space inside the office park, which will be a popular meeting place with its uniquely designed green areas. “Vodafone’s choice is further proof that there is still strong market demand for a modern, healthy and innovative office environment. The design of Budapest ONE and its forward-looking solutions allow employees to work flexibly in creatively designed spaces, in line with the expectations of a new era in the wake of the pandemic. The success of the first phase of development and the increased interest in the next two buildings show that well-located office buildings with people-centered solutions and services will continue to be sought after.” – emphasised Tibor Tatár, CEO of Futureal. In the selection of the new headquarters, location was also a key consideration, as Budapest ONE is located in Hungary’s largest multimodal transportation hub, connecting multiple modes of transport. The large-scale development, which will take place in Őrmező, one of the dynamically developing areas of Budapest, located at the junction of Kelenföld railway station, metro line 4, tram line 1 and several bus routes, as well as the Budapest stretch of the M1 – M7 motorways, can be reached on direct transport services from Budapest’s downtown in up to 10 minutes.