ProSite is the digital logistics solution from GF Piping Systems. It helps reduce administrative efforts of ordering, reordering, and accounting of piping system components. In addition, it simplifies the stock management of installation projects, reducing the necessary workforce and related costs to ensure that a sustainable and efficient solution is achieved.

Fifty percent of medium-sized businesses do not track their inventory. “The lack of tracked inventory can easily lead to out-of-stock situations. Not only does this threaten the timely completion of projects, but also the customer’s trust”, explains Bernd Schuster, Head of Global Specialized Solutions at GF Piping Systems.

Project managers regularly face inventory challenges, with lead times from distributors causing potential delays and additional cost to projects that are already under time pressure. Introducing a digital logistics solution makes the supply chain more cost-effective, as the carrying cost is optimized and simultaneously the person-hours needed for administrative tasks are reduced. Thus, translating into an efficiency boost of the whole production chain.

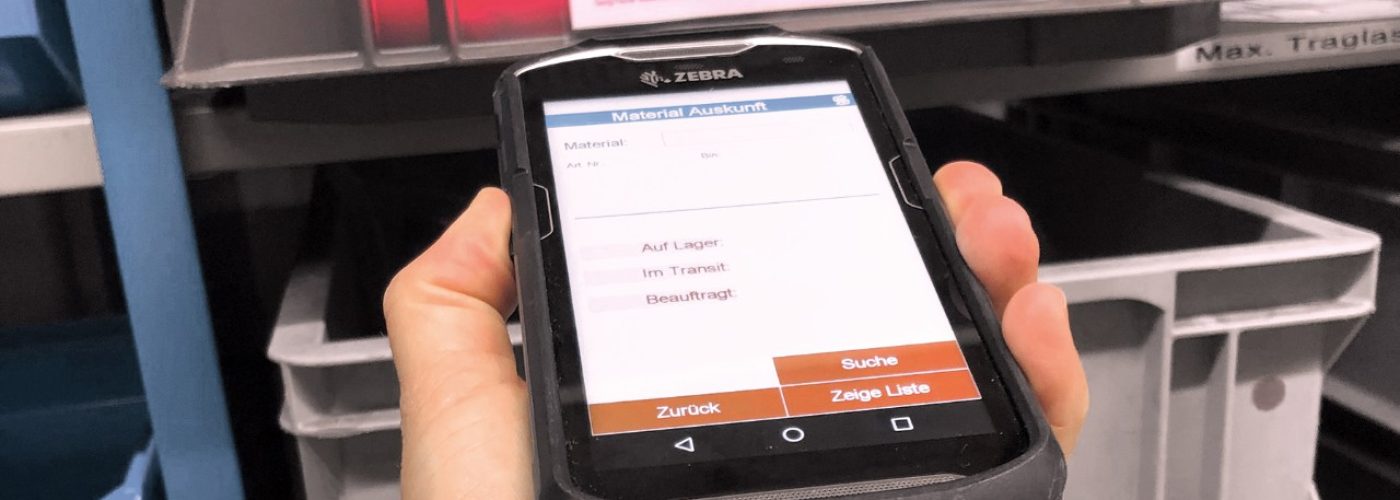

Nevertheless, there aren’t many digital tools for stock management available in the market that are affordable for medium-sized or small warehouses. Consequently, GF Piping Systems has developed ProSite, as a fully compatible solution that works with the devices already available on the project site, allowing them to professionalize their processes easily.

This powerful new digital platform can improve the production efficiency by up to 15% for some customers, saving them 20% of the administrative tasks in the end and bringing human error rates to the minimum. In addition, ProSite provides a fully traceable overview of the goods managed, ordering, and invoice process.

The new digital solution in GF Piping Systems’ portfolio helps to save warehouse space. The optimal inventory turnover ratio with automated just-in-time inventory management also significantly reduces administration and freight costs. At all times, the user can keep an overview of picklists and order books in a fully traceable and transparent manner. The fail-safe operation avoids excesses and shortages with staple material as well as custom pieces. In addition, the customer can keep the exact numbers required.

For more product details, visit: www.gfps.com/prosite