Safety on construction sites has improved greatly over the past fifty years. However, the latest report by HSE (Health & Safety Executive) shows that construction tops the most dangerous occupations in the UK for fatal injuries.

One of the main causes of fatal incidents for workers is being struck by a moving vehicle. In fact, when compared to the causes of non-fatal injuries, incidents involving a moving vehicle resulted in at least one death on all reported occasions in 2020/2021.

Since the introduction of the latest set of Construction Design and Management Regulations (CDM) in 2015, those found guilty of breaching health and safety rules have faced even heftier fines.

In 2021, BAM Nuttall Limited was ordered to pay more than £700,000 after an employee was run over and killed by a dumper vehicle at one of its sites.

The construction company was found guilty of breaching section 15 (2) of the CDM Regulations, which specify that a contractor must plan, manage and monitor construction work carried out either by the contractor or by workers under the contractor’s control, to ensure that, so far as is reasonably practicable, it is carried out without risks to health and safety. But what does this mean exactly?

In BAM Nuttall’s case, the HSE found that the company had failed to adequately assess the risks to their employees while they were repairing and replacing equipment. It also found that the company had failed to provide a place or places where such work could be carried out safely and which segregated people from vehicles.

Clearly, vehicle safety should always be taken seriously. But regulations can also be open to interpretation. Certainly, there are question marks over the duties and responsibilities of companies, operators and individuals when it comes to ensuring hazards posed by vehicles on worksites are prevented.

The CDM Regulations for vehicles state where a person may be endangered by the movement of a vehicle, suitable and sufficient steps to give warning to any person who is liable to be at risk from movement of the vehicle must be taken by either or both:

- the driver or operator of the vehicle, or

- where another person is directing the driver or operator because, due to the nature of the vehicle or task, the driver or operator does not have full visibility

Large construction vehicles are notorious for having complex and numerous blind spots and visibility has long been an issue for drivers and workers on the ground.

While the CDM Regulations don’t indicate precisely what the suitable and sufficient steps operators should take to prevent incidents are, it is clear that operators and their drivers have a legal obligation to ensure people are not endangered by vehicles under their control. In the event of an incident, an operator or driver could be prosecuted and face hefty fines if they were found to be in breach of these rules. So how can operators and drivers ensure they do not violate these rules?

Standards introduced by the industry, such as CLOCS, specify fitting vehicle safety equipment to address such safety concerns. This equipment includes technology like 360-degree cameras, radars and warning alerts.

Emily Hardy is a vehicle safety expert and Marketing Manager at Brigade Electronics UK – a leading supplier of safety devices and solutions for construction vehicles. She said:

“Construction sites can be extremely challenging and unpredictable environments. Therefore, maintaining safety at all times can be very difficult. On construction sites, the need for safety is paramount, particularly as the slightest mistake can have devastating consequences.

“Smart technology is helping to address the problem of restricted visibility and blind spots on vehicles operating on construction sites. These include the very latest RFID (Radio Frequency Identification) technology, such as Brigade’s ZoneSafe proximity warning system.”

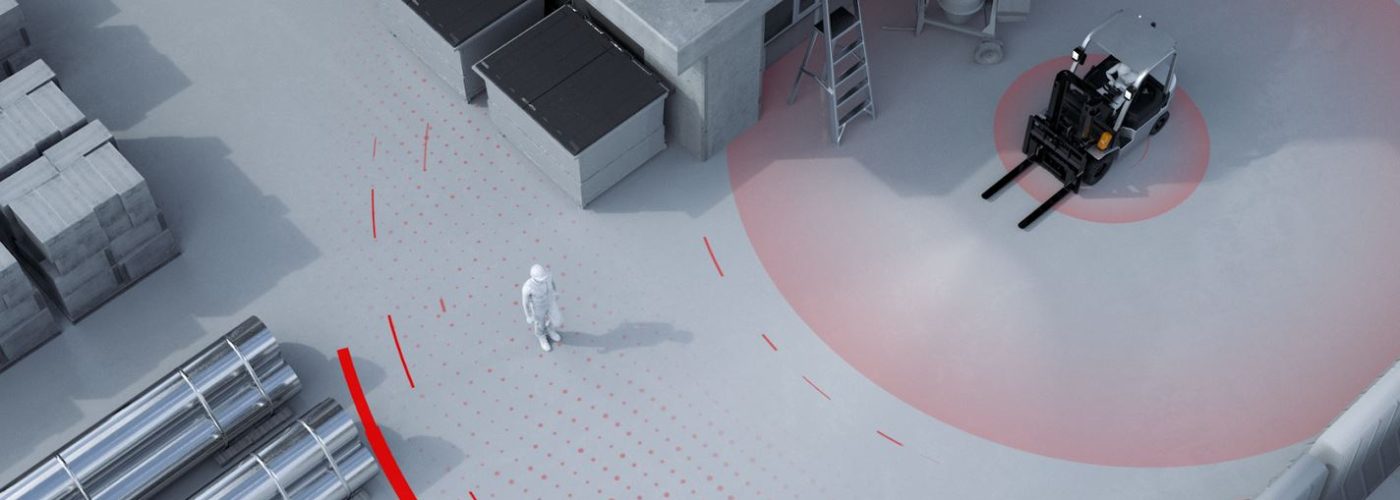

Ideal for construction sites, ZoneSafe usesvehicle-mounted antennas that communicate with detection tags, which can be worn by workers, set up in restricted areas or placed on objects or property. When a tag enters a detection zone, the vehicle operator will automatically receive a visual and audible alert via the in-cab control unit, which will enable them to take the necessary action. Tags worn by workers on foot will also vibrate to warn of an approaching vehicle.

Due to the RFID technology, which does not require line-of-sight, tags will be detected regardless of obstructions, blind spots, adverse weather conditions or poor visibility. Each tag can be uniquely identified and linked to individual people.

Emily continued:

“This technology is ideal for all types of construction vehicles that frequently operate within close proximity of workers and other machines. The system provides fast, reliable and accurate data exchange without any limitation on the number of tags or antennas in operation, making it perfect for large areas like busy construction sites.”

As the industry prepares for Hillhead in June, safety remains top of the agenda.

Emily added:

“Driver training is key to ensuring safety standards are adhered to. However, vehicle safety technology can add an additional layer of security and peace of mind for operators who are keen to ensure that their workplaces remain hazard free.”

Brigade Electronics will be attending Hillhead 2022 at Hillhead Quarry Buxton Tuesday 21st to Thursday 23rd June and exhibiting its range of plant and construction vehicle safety systems, including ZoneSafe. Find them at Stand RF1.

Building Design and Construction Magazine | The Home of Construction & Property News