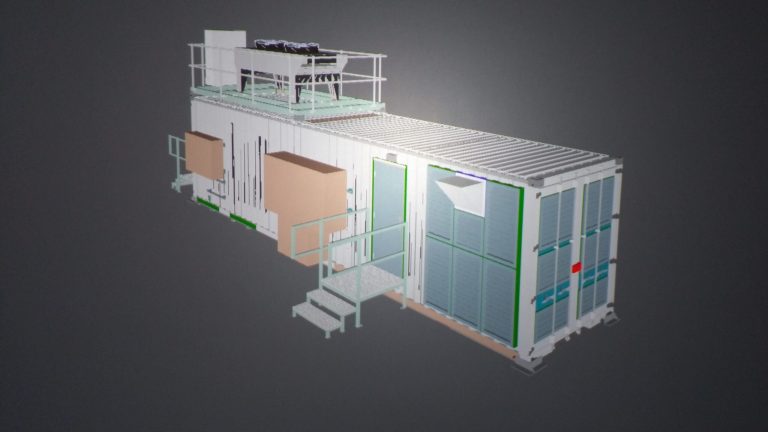

Modern Methods of Construction have been a hot topic for a number of years now. However, one of the areas often over-looked is the humble container; a ready-made structure that, with the right modifications, can create the ideal workshop, office, retail unit, plant room, datacentre, or classroom. Here, conversion expert Andy Capella from S Jones Containers discusses the benefits of using containers, modular buildings, and some of their most popular applications. Used correctly, containers can be one of the most versatile, durable, low impact and easily transportable building materials known to man. While high-end home designs tend to hit the headlines thanks to programmes like Grand Designs, there are a number of lesser-known practical applications that can help stimulate economic growth, expand classroom sizes and drive R&D. Offices, workshops, and retail units Self-contained, adaptable, low impact and zero maintenance are just a few of the reasons Staffordshire County Council recently specified 12 containers for a start-up development at Silverdale Enterprise Centre in Newcastle-under-Lyme. The county council operates a number of enterprise centres and workshop units across Staffordshire. Its earliest units date back to the early 1980s and have been a fundamental part of economic regeneration. With high numbers of people furloughed, facing redundancy, or simply reassessing their options due to the Covid-19 pandemic, the council encountered unprecedented demand for new start up spaces. With all of the units at Silverdale Enterprise Centre at full occupancy, the county council opted to expand their available workshop units by installing specially modified containers in an unused part of the site’s car park. Finished to a high standard complete with insulation, electrical ports, and French doors, the units were modified offsite and delivered ready for use, minimising disruption caused by construction work for the local community. Built to last as long as 25 years, the new units are set to provide a secure space for more than 1000 start-up businesses over the coming decades, with the county council able to transport the units to meet demand across its estate. It’s not just offices and workshops containers are increasingly being specified for though. Flexibility and ease of transport is also making them a popular choice for retail. One of the most recent requests we’ve received is the development of a new unit for a business hiring out electric bikes. With containers requiring little to no groundwork, the unit can be transported into central London and moved in-line with consumer demand and footfall. Containers are often being specified for start up businesses as they represent a lower investment than bricks and mortar or a long-term lease and provide the business owners or investors with an asset that can be resold or redeployed as needed. Schools, colleges, and universities Modular buildings are another flexible space solution being used increasingly for commercial purposes. Unlike containers, modular buildings are configured to spec by combining individual cabin modules that can be extended and adapted at any time to meet customers’ needs, whether temporary or permanent. For example, one of the major obstacles facing schools, colleges and universities right now is a lack of available teaching space. With major expansions costing millions of pounds and often taking months or even years to complete, the minimal on-site disruption, lower cost and rapid turnaround of modular buildings makes them an understandably popular choice for solving this problem. As the name suggests, one of the key benefits of modular buildings is how versatile and extendable they are. Depending on the customer’s needs, the individual units can be connected seamlessly via wall panels and partitions to create large open plan spaces that are ideal for classrooms, offices and countless other applications. In fact, this modular style of building has proved so popular that there is now an off the shelf option that includes high-level insulation and fire safety ratings as standard. Through modular construction we can create spaces as large as 640 square foot and up to three stories high. Industry and R&D There are, however, some applications where a regular shipping container is a more suitable foundation to work from. One such area is high-level manufacturing, engineering and R&D which often require self-contained, off-site spaces within which plant processes and equipment testing can safely and compliantly occur. For instance, there’s been a huge surge in demand for lithium-ion battery manufacture and storage sites, in line with advancements in technology. Secure, transportable and endlessly customisable, shipping containers are increasingly being used as the spaces within which ground-breaking new technologies, processes are being created, tested and refined, and where high-value labs and machinery are being housed. Using 3D CAD, we’ve helped develop high-tech units that can be shipped to wherever they’re needed most all over the world. One of the advantages for industry is that containers are often a lot more robust that conventional temporary structure building materials. They’re built to transport 20 to 50 tonnes, so to put heavy plant machinery in there is no problem at all. Also ideal for site expansions, a container can quickly and effectively be modified to become boiler or compressor housing and where needed, attached to the existing building. Ultimately, using a container ensures that the machinery is safe, secure, and protected from the elements with little to no need for maintenance. From sophisticated container conversions with complete with state-of-the-art fire suppression through to almost limitless flexibility of modular buildings, MMC are undoubtedly here to stay and are only going to grow in importance as emphasis increases on sustainability, reduced costs and low impact design. It’s perhaps ironic that an invention of the 1950s continues to act as the basis for many solutions to the issues created by our rapid rate of technological and cultural change in the 21st century, whether that be in advancements in renewable technologies and processes, increasing populations or changes to working and shopping habits. The original design principals of safety, security and durability remain the same, the only difference is that we can now apply them in many more ways than was originally intended. Andy