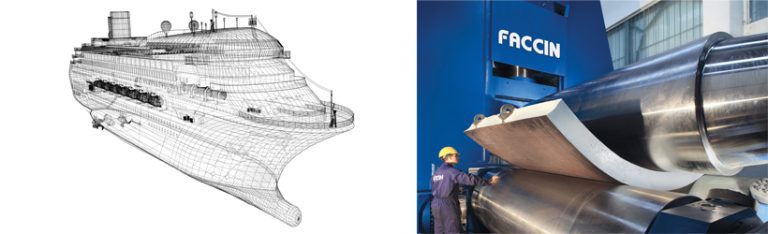

A shipbuilding company differentiates itself when it can build all types of vessels, regardless of their complexity, from cruise liners to mega yachts, from military ships to high-tech offshore vessels. In addition to a very competitive market, another big challenge for shipbuilding companies is that the design of ships is constantly changing to become increasingly highly efficient and sustainable for the environment. On account of this, a highly adaptable production with technologically advanced machines becomes the key to a successful operation. Faccin Group’s solution for the shipbuilding industry Nowadays, most companies use production techniques that have become obsolete. They are time-consuming, imprecise, and unsafe and require highly skilled operators, especially when producing very complex shapes like hull panels. Faccin Group, one of the world’s leader brands for the metal forming industry needs, has developed over the years the widest range of dedicated solutions for the shipbuilding industry, which include: Challenges and opportunities in the industry The key point is always to make diagnostics and maintenance simpler, faster, and therefore more efficient. All Faccin Group’s machines can thus be equipped with the latest evolution of the SIEMENS PGS-ULTRA CNC, recognized as the most technologically advanced solution on the market. This revolutionary system is based on GUI technology (Graphic User Interface), which guides the operator over all the programming steps, including the possibility to determine the welding point. As a result, all the information needed by the CNC to calculate the sequence of movements of pre-bending and rolling processes is simply provided by: Faccin Group’s main goal is to provide end users with cutting-edge solutions that give them a competitive advantage in a very aggressive worldwide market. Thanks to the highly advanced features offered by these solutions, the goal has been accomplished. Moreover, all these machines are prepared for “Industry 4.0” to be connected to the customer’s network and consequently improve the working conditions, increase productivity, and upgrade the quality of the final product. The production manager can easily manage remotely the machine and, at the same time, have a clear picture of the machines’ status and production output. In addition, Faccin has developed a new and safe cloud-based RSM remote service management control system to offer fast support and proactive maintenance and to give the possibility to check not only the HMI but any accessory mounted on the machine having an ethernet plug. Through an extensive network of subsidiaries, Faccin Group provides thorough sales and after-sales services worldwide.