Formwork, falsework, heavy duty support, ground shoring and safety & access systems specialist Altrad RMD Kwikform (Altrad RMDK) has provided temporary works to assist with the construction of 19-35 Baker Street.

19-35 Baker Street is a 10-storey commercial, retail, and residential mixed-use building in the West End of London, constructed by Laing O’Rourke on behalf of Derwent London. The project comprises 298,000 square foot of high-specification office space and 51 residential units, including an allocation for affordable housing. At the ground-floor level, the retail units fronting Baker Street, George Street and Gloucester Place will be linked by a central courtyard spanning the length of the site.

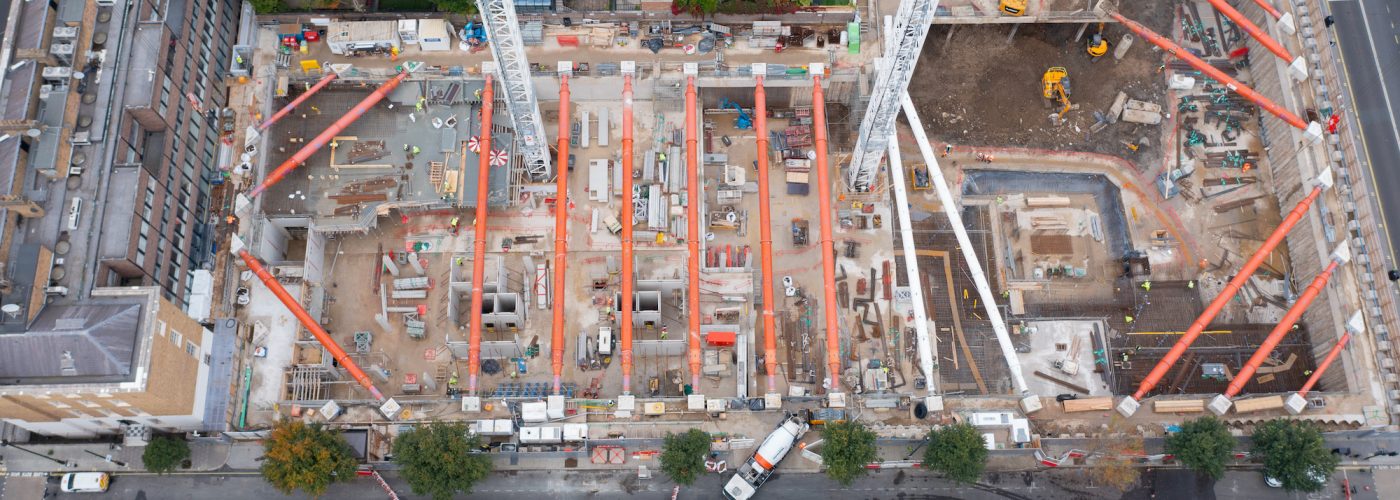

Altrad RMDK supplied 19 Tubeshor props of 610/1060 diameter – with the longest prop spanning 39m – to support the single-level basement excavation, from which 98% of waste from the overall project has been diverted from landfill and recycled and repurposed during construction.

All support equipment supplied for the project was CE-marked, which is a unique proposition from Altrad RMDK. It is the only UK supplier to offer equipment with full European compliance across its ground shoring fleet, which conforms with relevant EU design codes, material quality and manufacture under the controls of EN1090 legislation.

The hybrid hydraulic ground shoring props are fitted with mechanical screw collars, which is another unique feature exclusive to Altrad RMDK. This innovation isolates the integral hydraulic cylinders after the prop pre-loading stage, preventing the chance of prop release resulting from hydraulic failure while providing a more robust and stiffer propping arrangement with higher deflection control.

The Tubeshor 1060 props were also fitted with pre-camber shims placed between the bolted ring-flange joints. These boost the axial capacity of the props by reducing the amount of self-weight sag. Further prop performance benefits were afforded by inclusion of the unique Tubeshor Spherical Bearer end detail, which eliminates load eccentricity in both axes whilst providing 5° full circle rotation for on-site flexibility.

In addition to props withstanding earth and surcharge pressures, there are daily fluctuations in prop forces due to thermal conditions, including daily and seasonal temperature fluctuations combined with the effects of solar gain; whereby props exposed to direct sunlight will attract more load than those providing support in shaded areas – all of which must be considered when calculating prop loads.

Due to the sensitive nature of the city-centre site, wireless monitoring was selected which enables the site team and Altrad RMDK engineers to monitor prop loads 24/7. Alerts for prop loads outside of defined, scheme-specific values can be sent to customer and Altrad RMDK engineers, enabling any appropriate mitigation measures to be quickly identified thus ensuring the security of the excavation perimeter.

Ajay Nagah, Commercial Manager – Ground Shoring, at Altrad RMDK, explains: “This project highlighted our ability to offer optimum wall support for basement construction – producing lean solutions whilst not compromising on quality or performance.

Garrett Durkin, Laing O’Rourke Structures & Facade Project Leader, on the Baker Street project added:

“This project posed engineering challenges that required a bespoke approach in order to meet the stringent allowable movements, of which Altrad RMDK were professional in their approach from concept right through to install and removal.

“As the project challenges changed the Altrad RMDK team were always present and willing to support the Laing O’Rourke project delivery team with engineered solutions.”

Building, Design & Construction Magazine | The Choice of Industry Professionals