From industrial applications to artistic ventures, laser-cutting techniques have gained widespread popularity. It’s not difficult to see why – these techniques offer unparalleled precision and efficiency. But like any technological advancement, it’s crucial to examine its environmental implications.

The Basics of Laser Cutting

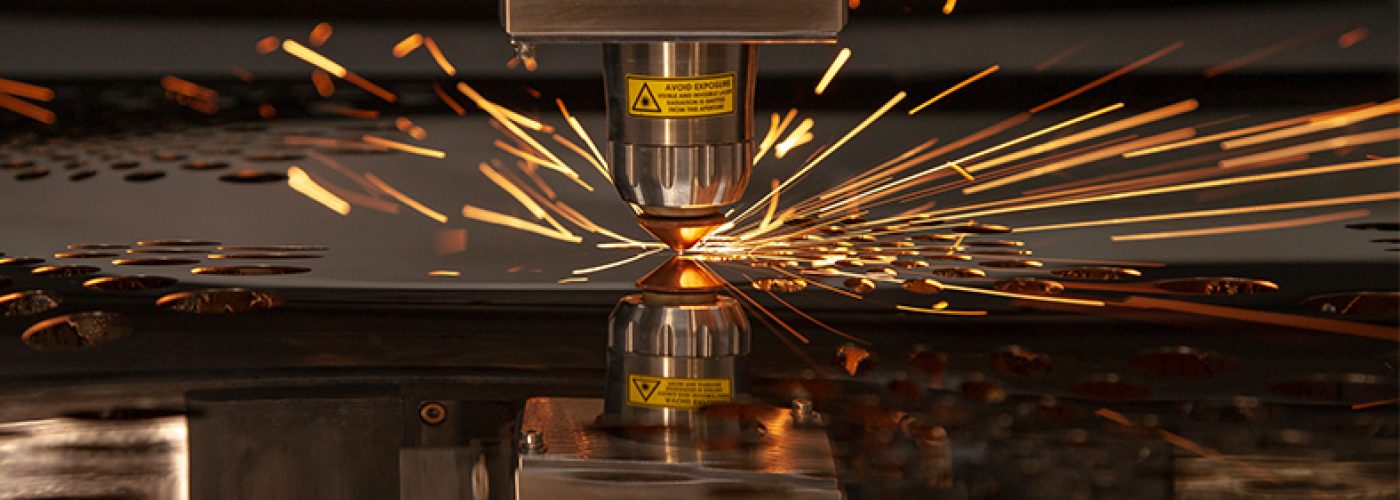

Laser cutting operates by focusing a high-powered laser beam on a specific point in a material, either melting, burning, or vapourising the substance.

Materials commonly used include metals, plastics, wood, and more. The efficiency of this process results from its precision, speed, and repeatability. Yet, as with all manufacturing processes, it’s essential to understand its environmental footprint.

Air Quality Concerns

- Emissions and Fumes: Laser cutting, especially when applied to certain plastics or metals, can release harmful fumes into the environment. If not adequately ventilated or filtered, these emissions can have detrimental effects on both human health and the surrounding environment.

- Particulate Matter: The process can also produce fine particulate matter, which, if inhaled, poses significant health risks. Proper extraction systems are necessary to minimise this impact.

Material Waste

While laser cutting provides a high degree of accuracy, there is always some material wastage. Unlike traditional cutting techniques, laser cutting can be optimised to reduce waste.

Digital models help operators maximise material usage, leading to a more sustainable production process. The Engraving People, for instance, are among those who champion the efficient use of resources, highlighting the balance between innovation and sustainability.

Energy Consumption

Laser cutting, particularly when using high-powered lasers, consumes a significant amount of energy. It’s crucial for operators to consider not only the energy source, but also their assist gas. While traditional methods rely on bulk deliveries of nitrogen, on-site nitrogen generators can improve efficiency and reduce the environmental impact. Renewable energy solutions can further mitigate the carbon footprint of these operations by powering both the laser and the nitrogen generator.

Furthermore, machine maintenance and ensuring the laser cutters are operating at optimal efficiency can reduce unnecessary energy consumption.

The Upside: Reduced Physical Waste

- Precision: The precision of laser cutting means fewer mistakes and, subsequently, less waste. Traditional cutting methods might need multiple attempts or produce errors, leading to material wastage. Laser techniques can precisely and repeatedly produce the same cut, minimising errors.

- No Tool Wear: Unlike physical blades or drills, lasers don’t wear down with use. This eliminates the need for frequent replacements and reduces the environmental impact of discarded tools.

The Water Footprint

Some laser cutting techniques, especially when dealing with metals, employ water jets in the cutting process or use water to cool down the equipment. This usage raises concerns about water consumption and the potential for contamination.

Implementing water recycling systems or using closed-loop cooling systems can help alleviate these environmental concerns.

The Path Forward: Sustainable Laser Cutting

To harness the full potential of laser cutting techniques without compromising the environment, here are some steps industries can adopt:

- Regular Maintenance: Regularly servicing machines ensure they operate at peak efficiency, consuming less energy.

- Embrace Renewable Energy: Powering operations with renewable energy sources, like wind or solar, can significantly reduce the carbon footprint.

- Effective Ventilation and Filtration: Employing high-quality air extraction and filtration systems can minimise air pollution and protect workers.

- Material Consideration: Opting for materials that produce fewer emissions when cut can also reduce the environmental impact.

- Training and Education: Educating operators on the environmental implications and best practices can lead to more sustainable operations.

Conclusion

Laser cutting, like any manufacturing technique, comes with its set of environmental challenges. But with conscious effort and technological advancements, it’s possible to engrave a future that’s sustainable and innovative.

As the demand for these techniques grows, it becomes increasingly important for industries to adopt eco-friendly practices, ensuring a balanced coexistence of technology and nature.

Building, Design & Construction Magazine | The Choice of Industry Professionals