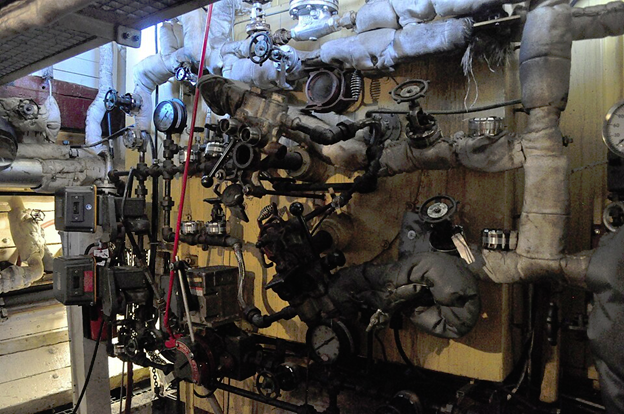

Industrial boiler systems such as those in ships, need maintenance so they can perform their best, and this includes having the right tools. As the one running these jobs, you need a trusted partner who will be able to achieve the highest possible efficiency when cleaning the pipes of a boiler because, over time, soot can accumulate, leading to costly repairs.

Incorporating a high-quality compressed air cleaning system that can work in small spaces will keep your boiler running smoothly. Know that debris can restrict the transfer of heat, forcing the system to work harder and increasing operational expenses. Worse, neglect can mean extended downtime with a higher repair cost, so you need the best tools to ensure that your industrial shipping operations are met.

What Are the Different Cleaners to Know?

There are a lot of tools that one can use depending on the type of residue that’s present inside a tube. Generally, companies use a mechanical cleaner where brushes are inserted manually into the tube to scrape the remaining ash. It’s going to involve a long rod that operators use, but this is going to be labor-intensive, especially if larger systems are involved.

These brushes can be made up of nylon while others prefer brass, and each of them has its pros and cons. Other materials are for heavy-duty cleaning so it’s best to ask the manufacturers for more information about how you can better incorporate them in your daily tasks.

Meanwhile, pneumatic cleaners are more advanced solutions that are available from trusted brands. This specific boiler tube cleaner from Putzmaus America is going to use specialized compressed air that will result in a gentler scrubbing action. It’s more consistent, and it’s great for high-frequency use, so it is perfect for industries that have round-the-clock operations. These types are known for their safety, and the tube surfaces on the interiors will have low wear because these tools don’t generally scratch the surface, and they are great for long-term use.

Others are using chemicals that are going to remove stubborn debris, and they are going to involve the circulation of chemical agents that can dissolve the carbon deposits without damaging the pipes. They are also great for dissolving limescale which is a white-chalk substance that forms in areas where water is present. However, using chemicals will mean proper preparation, and they should be disposed of carefully, so they may only be best for infrequent maintenance.

Which One Is the Right Choice for You?

The appropriate cleaning tool will depend on your needs, and there’s no right or wrong in these approaches. You need to understand the layout of the pipes and assess its daily operations to determine if it needs daily cleaning, and if so, the pneumatic system with its stainless-steel brush can provide the best possible results. For those smaller systems, the manual methods may be enough, but they may require more labor before they can become effective.

The nature of the deposits should be taken into consideration, where light soot can easily be removed with simpler brushes. However, it’s another story if you’re dealing with carbon deposits because they often require a more aggressive approach. See if you’ve chosen a tool that’s going to reduce the number of cleanings required so you can avoid unnecessary wear and tear on your boiler, and at the same time, save a lot on your resources.

Also, everything should be easy to use, and the maintenance teams should have knowledge about how these tools operate. It’s best if they have undergone training since user-friendly cleaners are going to result in a more consistent cleaning schedule, and this is a hassle-free process where the staff is more likely to finish the job on a regular basis rather than delaying the cleaning.

It’s also important to invest in a reputable manufacturer of these tools because they offer non-abrasive brushes that are trusted by various industries. Many of their products are known for their durability, so you’ll get a return on your investment as soon as possible.

What Are the Benefits of Routine Cleaning?

Washing the boiler pipes helps extend the lifespan of your equipment and significantly improves energy efficiency. Lower utility costs and reduced strain on your system mean you’ll start seeing a return on investment fairly quickly. For facilities looking to streamline their maintenance process, partnering with a reliable commercial boiler service provider can ensure that routine cleanings are done right—making the job easier for your staff and minimizing costly downtime.

Also, with the downtimes reduced drastically, your shipping operations will be more profitable. Avoid emergencies in the form of sudden shutdowns by having a clean boiler system. Get a service that’s uninterrupted with just the right brushes and avoid hazards as well.

Remember that a well-maintained tube is also going to be more eco-friendly because of the lower carbon emissions produced by the boiler. Many companies are pursuing sustainability because they have environmental goals and cleaning with the right tools can mean supporting green practices. See more info about a marine boiler when you go to this site here.

Overall, investing in the right cleaning tools will make life easier and operations more profitable. You just need to choose a trusted partner that serves a lot of esteemed companies in your industry, so you’ll have a tube cleaner that’s reliable and has a compact design.