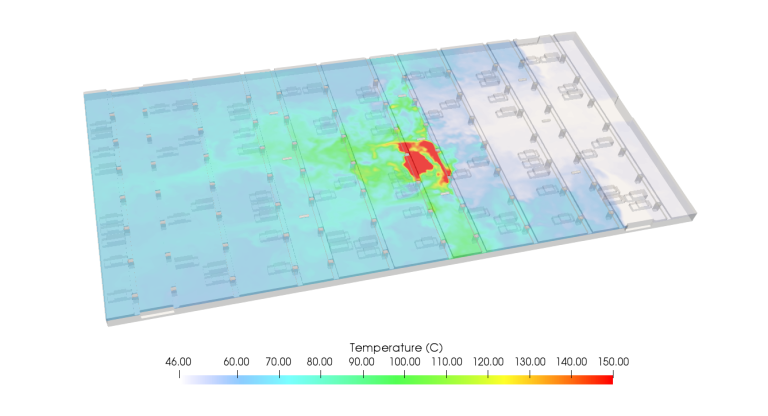

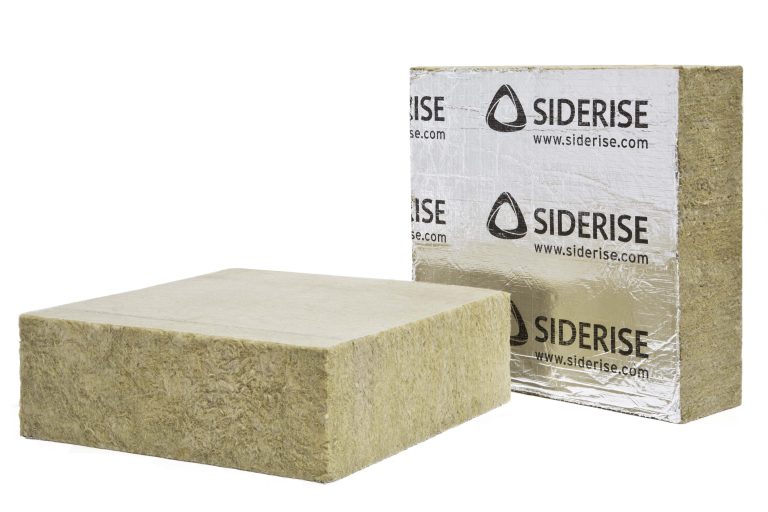

Framework Initiative will be made available to public bodies across England and Wales. A London housing association has launched a £2.4bn framework for public bodies to use for fire safety remediation works. Hyde Fire Safety Works and Services Framework, which is being procured by Hyde Housing Association, will cover a range of works, goods and services relating to fire safety. The framework, which is open to public bodies across England and Wales, is divided into 11 lots covering different types of remediation works to help make buildings more fire safe, with each of the lots being worth around £200m. The framework covers everything from supply and repair of fire doors, to the installation of sprinklers, to cladding remediation works. Each lot will run for four years, with between two and 10 bidders expected to be invited to tender. Firms can submit bids for all lots. Companies have until 5 August to register their interest, with shortlisted firms expected to be invited to tender on 18 August. Hyde Fire Safety Works and Services Framework Lots Lot 1 – Supply, installation, removal, and repair of fire doors Lot 2 – Supply, installation, removal, and design of fire safety signage Lot 3 – Supply, installation, removal, and maintenance of fire alarm, detection and suppression systems. (Lot 3 is split in to Lot 3A and Lot 3B to differentiate between fire detection and fire suppression systems) Lot 4 – Supply, installation, removal, and maintenance of emergency lighting Lot 5 – Design, supply, installation, removal, and maintenance of sprinkler systems and dry/wet risers. (Lot 5 is split in to Lot 5A and Lot 5B to differentiate between Dry Risers and Wet / Charged Risers.) Lot 6 – Provision of fire proofing and stopping works and services Lot 7 – Provision of cyclical and reactive electrical testing, servicing, and maintenance services Lot 8 – Remedial Works, upgrades, installations, and testing of electrical systems Lot 9 – Removed from framework Lot 10 – Design, supply, installation, removal, and inspection of cladding Lot 11 – Incident Management and provision of Business Continuity Planning advisory services to mitigate and plan for potential threats Lot 12 – Management Contractor to manage any of Lots 1 to 11 for clients and/or direct delivery