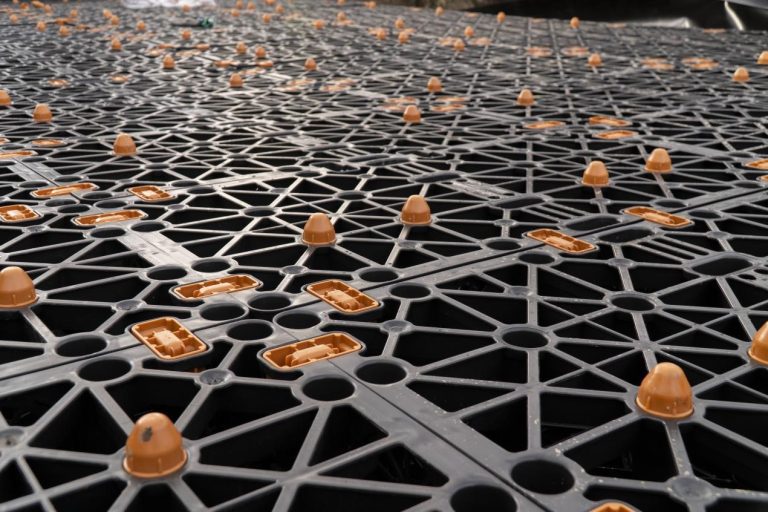

The high performance, reliable and easy-to-install Cascade Cast Iron Style Rainwater System from Brett Martin has been specified for a new housing development in Tutshill, Gloucestershire, the village where JK Rowling spent her childhood and which inspired many Harry Potter books. Located in the stunning Forest of Dean, on the banks of the River Wye near Chepstow, Birch Grove includes 45 new three, four and five-bedroom family homes all built to a high-specification for discerning buyers. In order to achieve the desired performance and aesthetics, housebuilder ButlerWall Homes chose a comprehensive and cost-effective range of rainwater and drainage systems which met their demands for quality, durability, low maintenance and ease-of-installation. The specification across these family homes included Brett Martin’s Cascade Cast Iron Style Rainwater System comprising a 112mm Half Round Gutter and 68mm Round Downpipe in Classic Black. Significantly lighter than traditional cast iron rainwater systems, Cascade is much quicker, easier and safer to install at height, helping to offer the developer huge savings in terms of on-site installation costs. The system also features external fixing lugs designed to facilitate the use of power tools, further speeding up installation. Fascia boards in Foil Black were also supplied by Brett Martin to provide a seamless match across the rooflines of the homes. In addition to the popular Classic Black colour specified on the Birch Grove Development, Cascade is also available in a further seven heritage colours including Anthracite Grey, Oxford Blue, Chartwell Green, Olive Green, Graphite Grey, Sandstone and Porcelain White – all of which cater to the subtle nuances of local vernacular architecture. The complete colour range delivers the traditional appearance of real cast iron with the convenience of modern plastic materials. Cascade is also UV stabilised for a maintenance-free system that will stay looking great and working well for years, and comes with a 10-year guarantee. The development also saw the installation of Brett Martin’s underground drainage systems including the new Adoptable Access and Inspection Chamber Assemblies. Using a reputable manufacturer such as Brett Martin offers far more than the quality and versatility of the product itself – they provide superior technical support, detailed installation instructions and maintenance guidelines to ensure rainwater systems perform exactly as promised. With this fabulous new village development now complete, Brett Martin’s Cascade Cast Iron Style Rainwater System and a range of underground drainage solutions have met the aesthetic and performance requirements of the developer whilst ensuring a fast, efficient and economical installation.