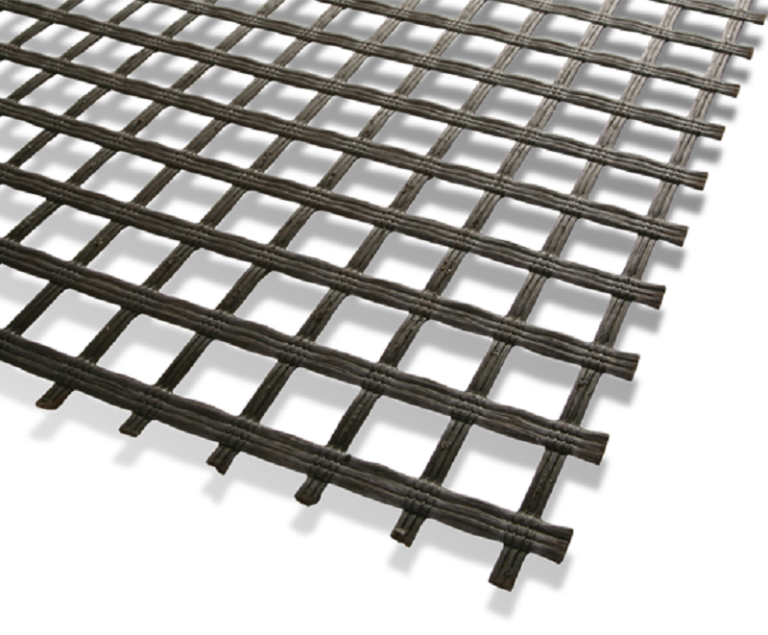

The Construction Trade Survey and the Department for Business, Energy and Industrial Strategy found that due to the rising cost of aggregate, construction firms are seeking out more cost-effective solutions. According to the Office for National Statistics (ONS), between 2010 and 2017, the average price of construction material rose 11.7%, while over that same period, the price of sand and gravel saw a hike of 26.6%. Moreover, ONS data shows almost 78 million tonnes of sand and gravel was sold in 2006, compared with the figures for 2016, which saw slightly less than 57 million sold. With the cost of transporting building materials increasing in line with fuel rises, aggregate has been described as the hidden cost driver among construction materials. Construction firms have to tackle the issue of price increases, especially since aggregate plays such a crucial role in concrete, construction fill, road construction and maintenance. One solution for firms looking to reduce their reliance on aggregate is to look at alternative technologies, such as geosynthetics and, in particular, geogrids. Geogrids are a polymer-based geosynthetic formed from interlocking geometric shapes. Incorporating geogrids in temporary working platforms, access roads and permanent roads can reduce the volume of aggregate needed, in some cases by up to 50%, and enable construction over weak ground. The use of this alternative solution has been steadily increasing over the last 30 years. “We are certainly seeing a growing acceptance of designs incorporating geogrids,” said Craig Roberts, Tensar Product and Technology Manager Walls and Slopes. “Clients, designers and contractors are realising just how beneficial they can be in improving construction efficiency, in mitigating ground risk and in reducing delays.” A study from the BAM Federal Institute for Materials Research and Testing shows that geosynthetics saw a worldwide growth of 8.9% between 2012 and 2017, due to its benefits, such as: savings through substitution or reduction of materials such as aggregate; savings due to ease of installation and reduced construction times; increased material longevity or reduction of maintenance; and improved sustainability. “The construction industry is under increasing pressure to deliver more for less,” said Craig Roberts. “It is essential for developers and infrastructure owners to maximise land use, minimise construction costs and deliver projects as quickly as possible, while maintaining profitability. Alternative ground engineering solutions, such as those incorporating geogrids, can go some way to helping achieve these ambitions.”