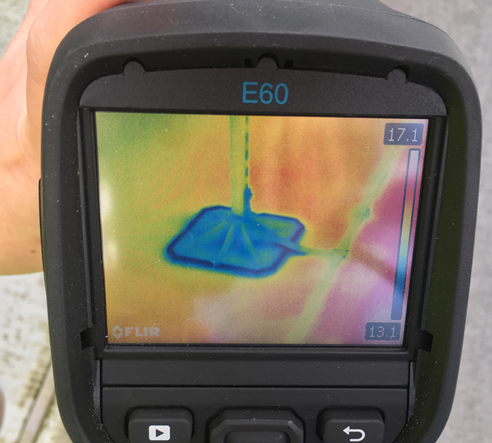

Regardless of whether the building is a commercial one or a house with a unique flat roof, most people know that flat roofs require more maintenance than standard pitched roofs. While it can be easier to build, the flat roof requires more inspections and maintenance to ensure everything functions correctly. The most difficult element about a flat roof is knowing when to replace the roof or if it requires a few repairs. This article will provide information on the most common types of flat roof repairs what you need to know. 1: Alligatoring One of the most common indicators that a flat roof needs to be replaced is the maintenance issue known as alligatoring. Alligatoring refers to the case when the asphalt used to build the roof has aged and lost elasticity resulting in a bubble and crack effect – similar to the skin of an alligator. Sadly, this means that the flat roof’s asphalt has become damaged to a state of no repair and will require replacement. Not only are we focused on putting in a good roofing solution that’s going to make clients happy, but we also take the time to help after the job is done. We take pride in the work being completed and therefore want clients to understand how to make sure the quality does not drop in the long-term. Roofers Wirral 2: Moisture And Leakage Another highly common issue experienced by properties with flat roofs is the leakage and lingering moisture. Fortunately, these problems can be dealt with effectively as long as one remains aware of them. As with all roofs, a flat roof develops leaks; however, as it is flat, the water does not have any place to go except straight down. This means the moisture will enter the roof and result in potential fungus and mould. One of the best ways to deal with moisture and leaks on a flat roof is by having it regularly inspected. Each time to you find an issue, repair and maintain the problem immediately. 3: A Buckle In Membrane The majority of flat roofs with asphalt are built in a similar way to pitched roofs because they have an asphalt-soaked membrane, and this membrane is spread across the top of the building. However, unlike the pitched roofs, the membrane of the flat roof is in a single piece and placed along the roof. This means that as time progresses the roof will settle and shift along with the property structure. Any excessive movement can result in buckling in the asphalt membrane, which can lead to breaks in the roof. A roof that buckles is not secure to live under and can lead to future problems. This is why it is best to have the membrane replaced as soon as it shows any buckling. 4: Pooling Water Due to the roof being flat there is nowhere for moisture to run when it rains. Moreover, when the house settles the roof can shift slightly, meaning it may not be as level as it was originally. This can cause water to pool in dips and divots. While the majority of materials are manufactured to hold up the water, the pools must be drained as soon as possible and check that the water does not seep into the lower layers of the roof. If pooling lingers, it is likely to deteriorate the exterior of the roof; thus shortening the lifetime of the roof. 5: Cracking Roof Flat roofs have a tendency for pressure to be exerted on them because they are not slanted. In some cases, the pressure can be built up as if the stress and pressure can be excessive. It can cause the roof to crack, and if it does crack you should contact a professional immediately. In addition, exposing the house to precipitation can result in roof cracking. This shows that the roof is structurally compromised and it is time for a new one. The majority of roofing work is carried out while the structure below is still occupied. That’s why we schedule and conduct our work with the utmost flexibility to suit your specific needs. We want to do our jobs while causing the minimum amount of disruption in your day-to-day life. Roofers Chester 6: Flashing As with various roofing materials, the asphalt flat roof tends to expand and contract with changing weather and temperatures. As time progresses, this continued expansion and contraction can result in flashing to pull away from the corners and edges of the roof; thereby, resulting in leaks and moisture being trapped in the roof. The best method of dealing with this issue is by inspecting and maintaining the roof regularly. When the leaks are significant or you have deterioration in the flashing, you will be required to replace the roof. If you have questions regarding the condition of the roof, or you think it is time to have the roof inspected, you should contact a roofing professional.