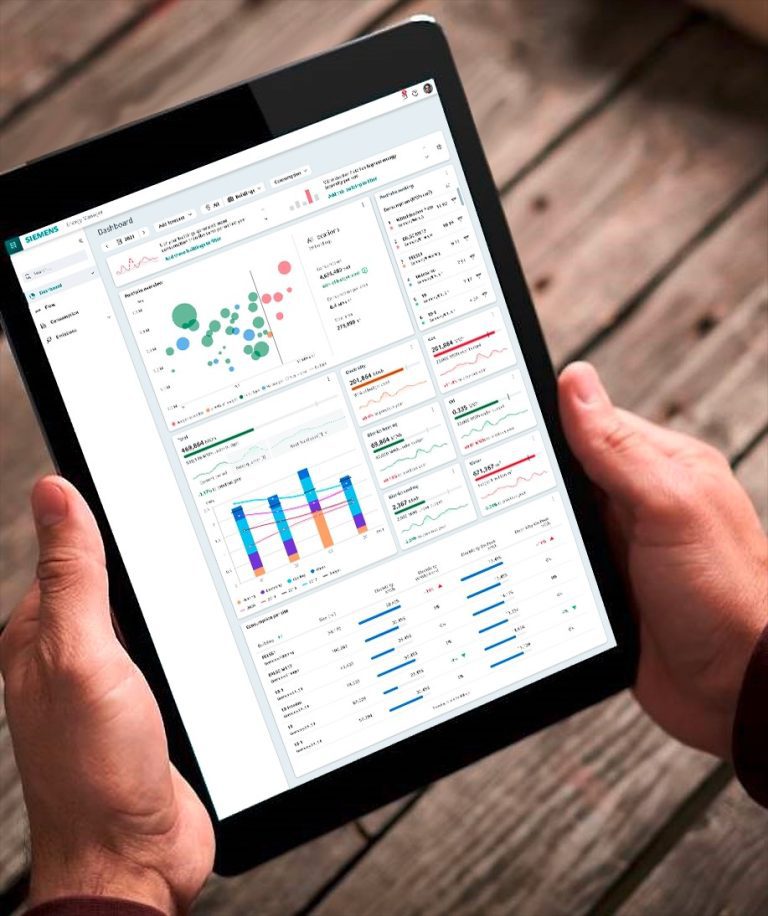

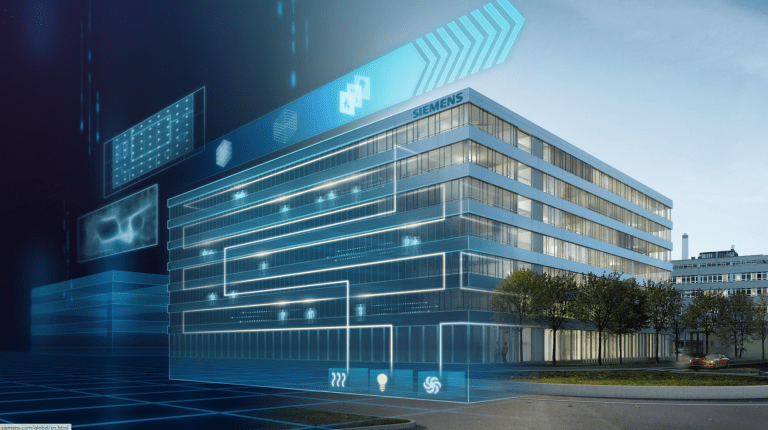

Building X is the first next generation offering designed and built as part of Siemens Xcelerator Modular, scalable, open smart building suite that seamlessly integrates building systems to eliminate complexity and enable net zero Facilitates co-creation with partners to address digitalization challenges faster Siemens Smart Infrastructure has launched Building X, a new smart building suite that is open, interoperable and fully cloud-based. The suite is the first next generation offering built on the design principles of Siemens Xcelerator, an open digital business platform launched today to accelerate digital transformation and value creation across industry, transportation, grids and buildings. Building X addresses the challenges of various stakeholders, including building users, property investors, real estate companies and facility managers. It acts as a single source of truth to eliminate complexity and supports net zero targets. Stakeholders can now digitize and use their building data from various sources, disciplines and systems on one single platform, Building X. This enables a seamless user experience and the integration of their existing software and ecosystem, including third party applications, through vendor agnostic connectivity and open application programming interfaces (APIs). The suite offers modular, AI-enabled applications, and built-in cyber security. It also facilitates co-creation with customers and partners to address their challenges faster, thanks to the openness and cloud technology, which means digital transformation can be achieved easier, faster and at scale. “Building X is the antidote to data silos. We can now connect all data that smart building systems generate in one single data lake, scaling up smart buildings faster and moving closer to our vision of autonomous, net zero buildings. Building X creates data-based outcomes for greater efficiency, performance and experience, changing for the better the way we work and live in buildings,” said Matthias Rebellius, managing board member of Siemens AG and CEO of Smart Infrastructure. “We look forward to co-creating use cases with our customers and partners on Building X to accelerate innovation and sustainability in the industry.” The Building X suite currently features a set of applications and digital services, tailored to different stakeholder groups, all connected on the AI-enabled platform. Building X opens new possibilities to digitalize, manage, and optimize building operations, bringing value to both existing buildings and new ones. Its applications cover key domains of building management, including energy, security and building operations, backed by strong analytics capabilities. The applications offer a consistent user experience, where relevant data is intelligently combined to drive outcomes for customers. A true digital building operations twin Building X combines the real and digital worlds of buildings by consolidating data from multiple sources into a digital building operations twin. With a virtual representation of a building, building operators can resolve issues faster. Users benefit from the transparency Building X provides in their efforts to make their buildings more sustainable, achieve better building performance and optimize user experience – all resulting in higher business outcomes. A growing set of applications The Building X applications are designed to be modular and persona-based, providing the right data to the right people. In addition to co-creation possibilities, users can choose from multiple ready-made applications. This makes the single “pane of glass” concept user and workflow-driven, while still allowing dashboards and data insights to be customized according to each user’s needs. As of now, the offering embraces four applications, with more to be added to the platform over time: The Energy Manager tracks energy consumption, costs and CO2 footprint of a building or building fleet and enables early corrective actions if necessary. It forecasts energy consumption based on historical data, and supports users in tracking their sustainability goals, helping them reach net zero buildings. The Operations Manager operates and monitors building equipment and applications in real-time. It can monitor a fleet of sites from one single point and ensures fast issue-response while reducing downtimes. Users benefit from increased business continuity and improved reaction times. The Security Manager operates and maintains security systems with unified and automated workflows. It centrally manages daily security operations and incidents across all systems. The 360° Viewer App represents a location as a virtual 3D environment, allowing for indoor navigation for insights into equipment topology and installation. SaaS and driving outcomes with building services Building X is offered as a SaaS (software-as-a-service) model, on a subscription basis. Thanks to the SaaS model, building stakeholders can access software off the shelf, ensuring they always have access to the latest functionality and find upgrades during the building lifecycle to meet their changing needs. Aside from the SaaS model, customers can also opt for an end-to-end program of Siemens Xcelerator Building Services, which will be enabled by Building X. This allows them to rely on Siemens to achieve their targets. In this model, Siemens leverages a combination of its technology, paired with the expertise of its digital building professionals. The programs are customized to achieve pre-defined outcomes, such as reducing operating and energy costs, optimizing asset performance for uptime and productivity, meeting regulatory requirements, or enhancing the occupant experience. Siemens Xcelerator is an open digital business platform comprising a curated portfolio of IoT-enabled hardware and software, a growing partner ecosystem and evolving marketplace to accelerate digital transformation.