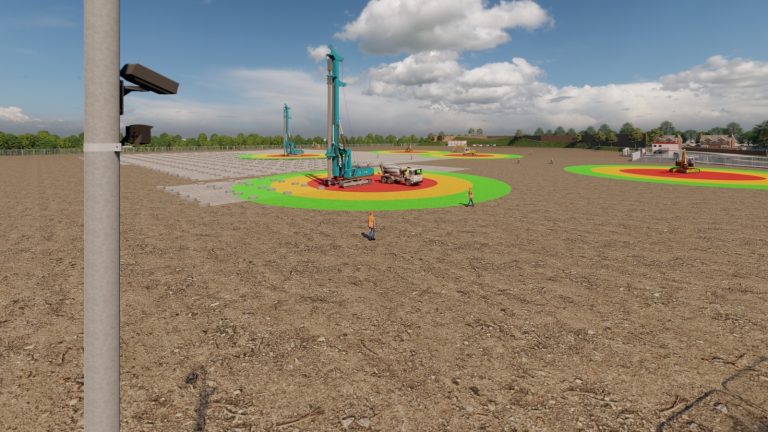

ASPEC – AI System for Predicting Embodied Carbon in Construction – Website Launches as Innovate UK Funding Period Concludes Winvic Construction Ltd, a leading main contractor that specialises in the design and delivery of multi-sector construction and civil engineering projects, and its partners in a cross-sector multidisciplinary research group is inviting people in the construction industry to register their interest to access a new embodied carbon analytics AI system. Professionals should visit www.carboncalculated.co.uk to join the mailing list and they will be able to access a free trial of ASPEC – which stands for AI System for Predicting Embodied Carbon in Construction – towards the end of the year. Winvic, University of the West of England (UWE Bristol), and Costain make up the consortium that was awarded £800,000 funding by Innovate UK in November 2020 to create a fit-for-purpose technology solution to help drive down industry carbon emissions and meet government’s green targets. The ASPEC website homepage, where professionals can register for the free trial Users will be able to upload a 3D BIM file – a Revit model – to the revolutionary web-based system and it will calculate the building or infrastructure project’s carbon output within minutes. Materials can then be altered within ASPEC to directly affect the real-time calculations of the carbon data – this allows construction schemes to be designed in a ‘green first’, non-time-consuming approach for the very first time. A short video about ASPEC can be found on the brand’s YouTube channel. ASPEC is integrated with the Government Green House Gas conversion factors, Inventory of Carbon and Energy (ICE) and the Environment Agency (EA), making it the largest database of environmental construction data in the world. Nevertheless, the system also allows users to upload their own materials databases which will work alongside the data points already available. Winvic and its research group partners have also been engaging with supply chains and other stakeholders throughout the two-year ASPEC project and 360-degree feedback has been employed to ensure the tool is user friendly and functional. Please see editor’s notes for caption to image of ASPEC The system will help to propel contractors and material manufacturing firms to meet the UK government target to remove 10MT of carbon dioxide by 2030. Furthermore, a 50 per cent reduction in carbon emissions has been set through the Construction 2025 strategy and the target for 2050 is to bring all greenhouse gas emissions to net zero. Winvic Digital Engineering Manager and ASPEC project lead, Morgan Hambling, commented: “When we started this Innovate UK funded project two years ago, embodied construction calculation methods were onerous at best and there was simply no efficient way for design teams to proactively reduce the carbon footprint of projects. Therefore, ASPEC is transformational for the industry as contractors, consultants and material manufacturers can at last sit in the driving seat with this fit-for-purpose cloud-based tool. “With the Innovate UK two-year funding period now over and development in its final stages, we’re now inviting people to visit the ASPEC website to register their interest. We’re looking for professionals to get hands on in a free trial towards the end of the year – this is just the beginning, where we can all make the real impact that is required to meet client and building occupier needs as well as important government and industry targets.” For more information on Winvic, the company’s latest project news and job vacancies please visit www.winvic.co.uk. Join Winvic on social media – visit Twitter @WinvicLtd – and LinkedIn. Building, Design & Construction Magazine | The Choice of Industry Professionals