Sheet metal bending is a process that involves shaping metal sheets into various forms using different tools and techniques. Sheet metal bending can be done for a variety of reasons, such as manufacturing parts, constructing structures, or even for decorative purposes. In this article, we’ll Hitherbest sheet metal fabrications have kindly given us some top tips for bending sheet metal like a pro.

Introduction

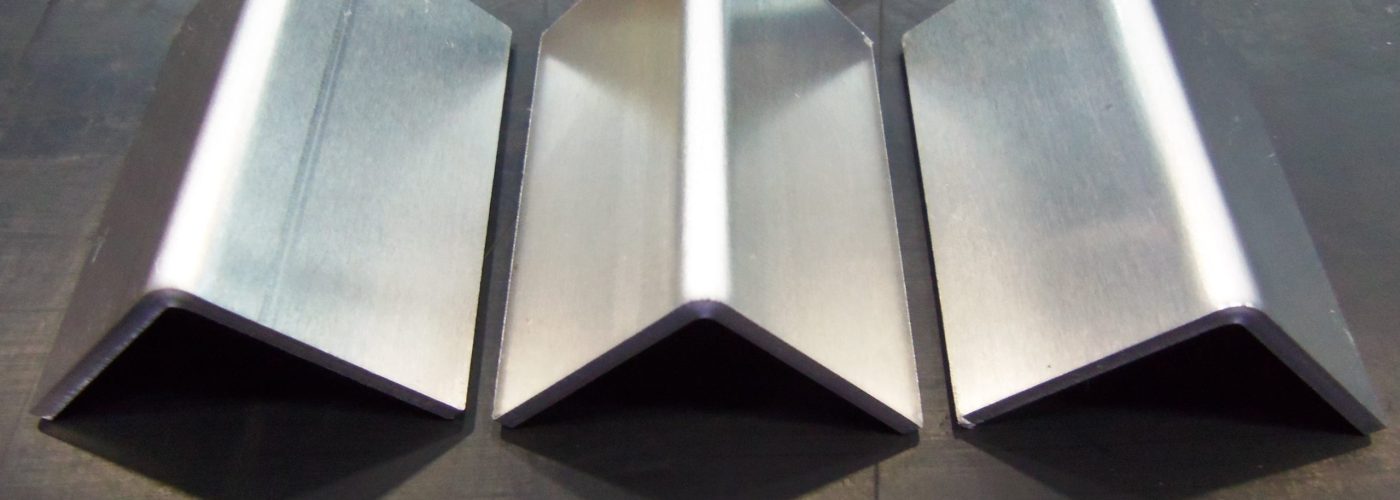

Sheet metal bending is a crucial process in metalworking that is used to shape a sheet of metal into a particular form. This process involves applying force to the metal sheet, which causes it to bend or deform into a new shape. Sheet metal bending can be done using different techniques, tools, and materials depending on the desired outcome. In the following sections, we will discuss the most common types of sheet metal bending, tools used, tips for bending sheet metal, and common mistakes to avoid.

Types of Sheet Metal Bending

There are several types of sheet metal bending techniques that can be used to shape a metal sheet, including V-bending, U-bending, air bending, and bottoming.

V-Bending

V-bending is a type of sheet metal bending technique that involves clamping the metal sheet between a punch and a die. The punch applies pressure to the metal sheet, causing it to bend into a V shape.

U-Bending

U-bending is another technique that is commonly used in sheet metal bending. This technique is similar to V-bending, except that the metal sheet is bent into a U shape instead of a V shape.

Air Bending

Air bending is a type of sheet metal bending technique that involves using a punch and die to apply force to the metal sheet, causing it to bend. Unlike V-bending and U-bending, air bending does not require the metal sheet to be clamped tightly between the punch and die.

Bottoming

Bottoming is a sheet metal bending technique that involves bending the metal sheet until it makes contact with the bottom of the die. This technique is useful for creating sharp bends in sheet metal.

Choosing the Right Tool for Sheet Metal Bending

Choosing the right tool for sheet metal bending is essential for achieving the desired outcome. There are several tools that can be used for sheet metal bending, including press brakes, folding machines, and roll bending machines.

Press Brake

A press brake is a tool used for sheet metal bending that applies force to the metal sheet using a punch and die. Press brakes are available in different sizes and capacities and can be used for a variety of sheet metal bending applications.

Folding Machine

A folding machine is a tool used for sheet metal bending that bends the metal sheet by clamping it and folding it using a moving beam. Folding machines are commonly used for creating box-like shapes in sheet metal.

Roll Bending Machine

A roll bending machine is a tool used for sheet metal bending that bends the metal sheet by passing it between three rollers. Roll bending machines are commonly used for creating cylindrical shapes in sheet metal.

Tips for Bending Sheet Metal

Bending sheet metal requires skill and precision. Here are some tips to keep in mind when bending sheet metal:

Measure Twice, Cut Once

Before bending the sheet metal, it’s essential to measure and mark it accurately. Double-check the measurements before making any cuts to avoid wasting materials and time.

Use the Right Tool for the Job

Using the appropriate tool for sheet metal bending is crucial. Choose the right tool based on the thickness and type of metal, the desired bend angle, and the complexity of the shape.

Properly Secure the Sheet Metal

To avoid the sheet metal from moving during the bending process, it must be securely clamped to the tool. Ensure that the sheet metal is straight and level before clamping it in place.

Avoid Over-Bending

Over-bending is a common mistake that can cause the sheet metal to crack or deform. Follow the recommended bend angles for the thickness and type of metal being used to avoid over-bending.

Use a Bend Allowance

A bend allowance is the amount of material that needs to be added to the sheet metal’s length to compensate for the metal’s deformation during the bending process. Using a bend allowance helps to achieve precise and accurate bends.

Use a Back Gauge

A back gauge is a tool used to ensure that the sheet metal is positioned accurately before bending. It’s essential to use a back gauge to avoid mistakes and ensure consistent results.

Common Mistakes to Avoid When Bending Sheet Metal

Bending sheet metal can be challenging, and there are several common mistakes to avoid:

Underestimating the Bend Radius

The bend radius is the radius of the metal’s inner surface during bending. Underestimating the bend radius can cause the sheet metal to crack or deform, resulting in wasted materials and time.

Neglecting Material Thickness

Material thickness is crucial when bending sheet metal. Neglecting the material thickness can lead to inaccurate and imprecise bends, resulting in wasted materials and time.

Improperly Positioning the Sheet Metal

Positioning the sheet metal incorrectly can lead to inconsistent and inaccurate bends. It’s essential to use a back gauge to ensure that the sheet metal is positioned accurately before bending.

Forgetting to Account for Springback

Springback is the amount of deformation that occurs when the sheet metal is released from the bending tool. Forgetting to account for springback can lead to inaccurate and imprecise bends.

Conclusion

Sheet metal bending is a crucial process in metalworking that requires skill, precision, and the appropriate tools. By understanding the various techniques, choosing the right tool for the job, following tips for bending sheet metal, and avoiding common mistakes, you can achieve accurate and precise bends in sheet metal.

FAQs

What is the best tool for bending sheet metal?

The best tool for bending sheet metal depends on several factors, including the thickness and type of metal, the desired bend angle, and the complexity of the shape.

What is the bend radius?

The bend radius is the radius of the metal’s inner surface during bending.

How do I avoid over-bending sheet metal?

Follow the recommended bend angles for the thickness and type of metal being used to avoid over-bending.

What is a bend allowance?

A bend allowance is the amount of material that needs to be added to the sheet metal’s length to compensate for the metal’s deformation during the bending process.

How do I ensure consistent results when bending sheet metal?

Using a back gauge to ensure that the sheet metal is positioned accurately before bending can help ensure consistent results.

What are some common mistakes to avoid when bending sheet metal?

Some common mistakes to avoid when bending sheet metal include underestimating the bend radius, neglecting material thickness, improperly positioning the sheet metal, and forgetting to account for springback.

How important is measurement accuracy when bending sheet metal?

Measurement accuracy is crucial when bending sheet metal. Double-checking the measurements before making any cuts can help avoid wasting materials and time.

What is the difference between a press brake and a roll bending machine?

A press brake is a tool used for sheet metal bending that uses a stationary bed and a moving beam to create bends, while a roll bending machine bends the metal sheet by passing it between three rollers.

What is the best way to clamp sheet metal when bending?

The sheet metal should be clamped securely to the tool to avoid it from moving during the bending process. Ensure that the sheet metal is straight and level before clamping it in place.

How can I avoid cracking or deforming the sheet metal during bending?

Following the recommended bend angles for the thickness and type of metal being used, using a bend allowance, and avoiding over-bending can help avoid cracking or deforming the sheet metal during bending.

Building, Design & Construction Magazine | The Choice of Industry Professionals