The intersection of the Internet of Things (IoT) and Building Information Modelling (BIM) holds immense potential. By integrating Forge’s intelligent models with Microsoft Azure IoT Hub, we open the door to vast possibilities, including advanced machine learning insights. In this article, we’ll explore how data collected using BIM 360 software can be linked with building equipment to monitor operations and perform predictive analyses, ultimately reducing maintenance costs.

A New Era in the AEC Industry

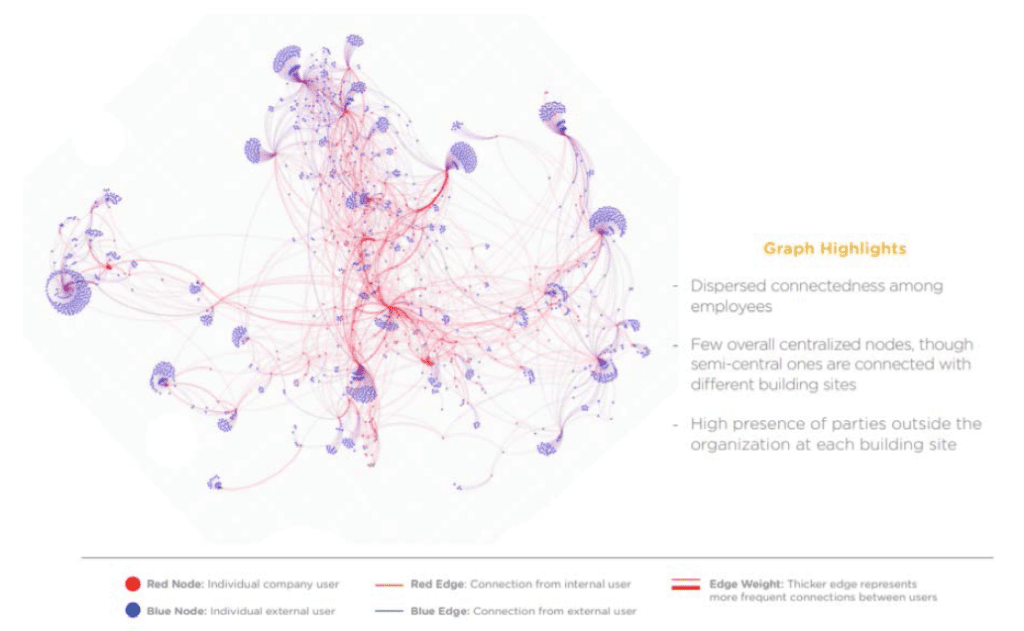

It’s no secret that the Architecture, Engineering, and Construction (AEC) industry is in dire need of digital transformation. For too long, manual processes and rework have led to significant financial losses. A graphic from Box.com research illustrates the typical collaboration challenges within the construction sector:

This graph highlights the fragmented nature of information within construction organisations. But how can we drive digital transformation in the AEC market?

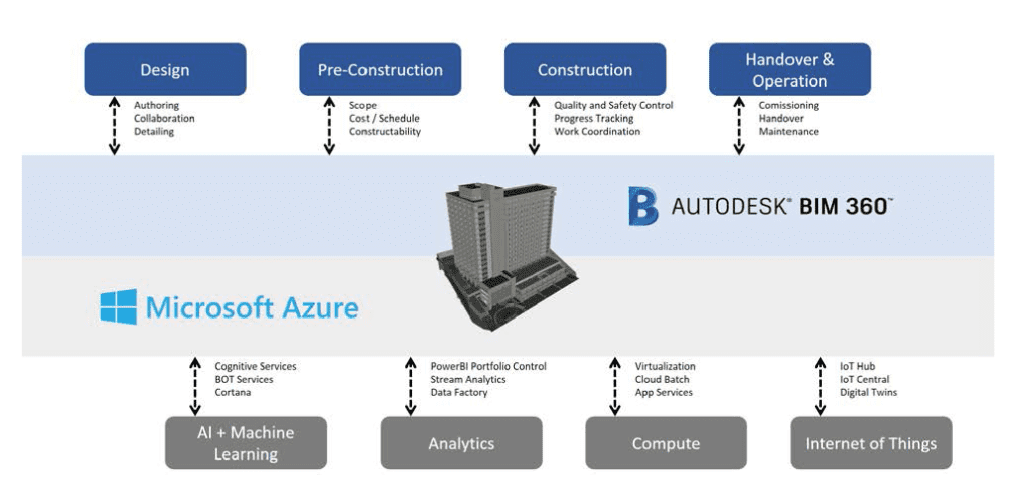

One promising avenue is leveraging available technologies. Autodesk’s cloud solutions, particularly BIM 360 products and Autodesk Forge, integrated with platforms like Microsoft Azure, have the potential to revolutionise the industry. These tools could eliminate the need for paper-based processes entirely.

Have you heard of the concept of a digital twin? This idea, featured in Gartner’s Top Trends for 2017, continues to influence how we operate today.

According to Gartner:

“Within three to five years, billions of things will be represented by digital twins, a dynamic software model of a physical thing or system… Digital twins function as proxies for skilled individuals and traditional monitoring devices… They will enable a more detailed digital representation of the real world for simulation, analysis, and control.”

To implement this technology, we need a digital model of a physical entity—whether it’s a machine, engine, or building.

But how do we create a digital twin, and what do we do once it’s established? Let’s explore the technologies that deliver the digital twin concept. BIM 360 and Autodesk technology provide the 3D digital model, which can be created using tools like Autodesk Inventor, Autodesk Revit, and Autodesk InfraWorks. BIM 360 allows cloud-based access to these models anytime, anywhere.

Microsoft Azure acts as the bridge, collecting data from sensors and linking them to the digital world. A comprehensive vision of digital construction is depicted below:

To better understand the integration of Autodesk BIM 360 with Microsoft Azure, think of Spider-Man. Initially, Spider-Man crafted a homemade suit. But after meeting Iron Man, Tony Stark developed a powerful new suit for him. This analogy is similar to how Autodesk BIM 360 becomes significantly more powerful when integrated with Microsoft Azure, as shown here:

So, how can this integration be accomplished? That’s the focus of this article.

BIM 360 as an IoT Hub

To begin integrating Autodesk BIM 360 with Microsoft Azure, we must decide what information to store in each product. In 2016, I delivered a lecture at AU titled “Useless or Priceless? How to Prepare and Use a BIM Model for FM and Building Ops,” which served as the foundation for this discussion.

For a digital twin, after preparing the model for facilities, BIM 360 Docs can host the 3D model, accessible via an external web application. I recommend visiting the Getting Started page of Autodesk Forge, the open API for Autodesk BIM 360, which provides all the necessary tools for developing integrations between Autodesk products and the Microsoft Azure cloud.

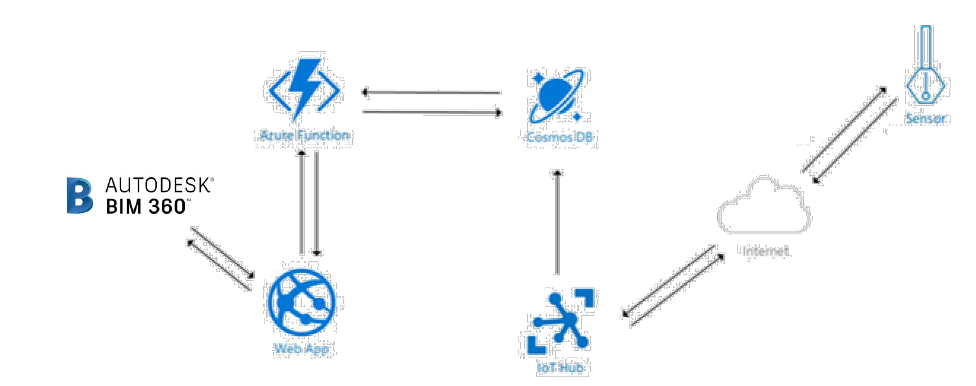

The architecture of this new web application is illustrated in the following diagram:

The web app will visualise the model integrated with data collected by sensors. What sensors are available on the market? Have a look:

Which sensors can we use in this architecture? Virtually any sensor that meets these criteria:

- Data encryption using a secure, publicly analysed symmetric-key algorithm (e.g., AES with at least 128-bit key length).

- Digital signature using a secure, publicly analysed symmetric-key algorithm (e.g., SHA-2 with at least 128-bit key length).

- Support for either TLS 1.2 or DTLS 1.2 for communication paths, with optional X.509 certificate handling.

- Updateable key-store and per-device keys, securely stored and capable of updates.

- Firmware and application software must support updates to address security vulnerabilities.

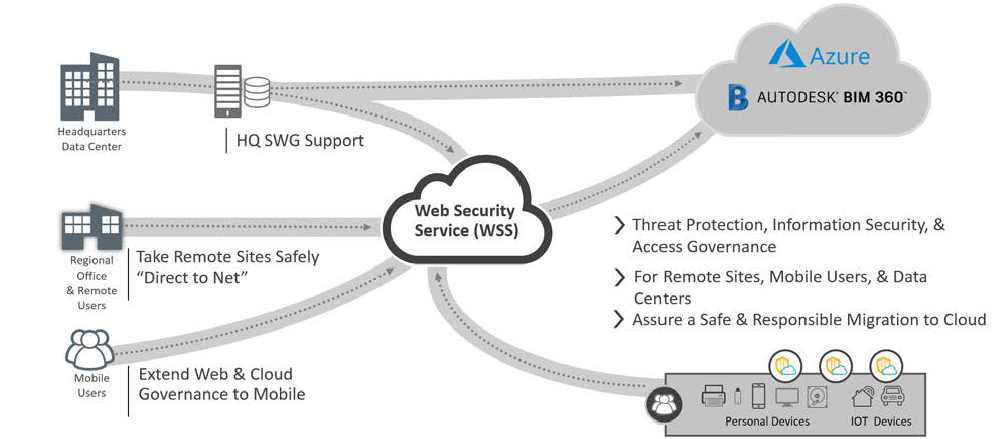

Security is paramount, so ensure that your cloud connectivity covers all these requirements. Additionally, since IoT sensors are exposed and connected to your network, implementing robust security measures is essential. Consider the following architecture for board security:

Remote and mobile users from various locations can connect to the Web Security Service, which offers universal connectivity. The core service provides strong access governance, threat protection, information security, and data loss prevention, ensuring consistent enforcement of security policies across devices and locations. WSS acts as a unifying gateway to the web and cloud, bringing control to potential chaos.

BIM 360 Build for Data Collection

Even though my 2016 lecture focused on BIM 360 Field rather than BIM 360 Build, the principles still apply. At some point, a new equipment workflow will likely emerge in BIM 360 Build, similar to that in BIM 360 Field.

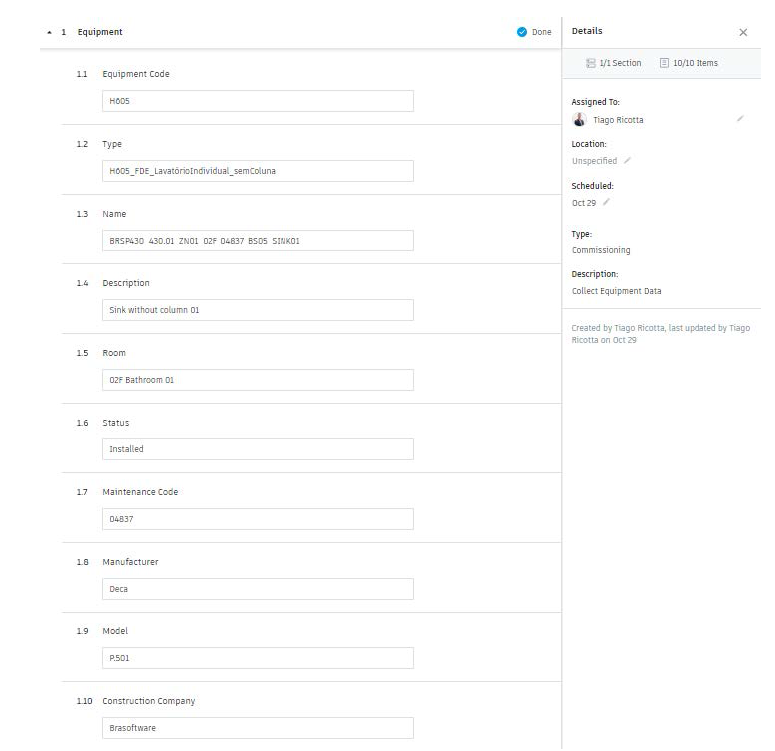

To collect data using BIM 360 Build, create a checklist with fields such as:

Field workers can complete the checklist using a mobile device, consulting the BIM model stored in BIM 360 Docs to identify the relevant codes.

To link the component in the BIM model with the component in Azure, use the parameter name. For example, a sink might be identified as “BRSP430_403.01_ZN01_02F_04837_BS05_SINK01.”

In the future, Forge API could be used to recreate the equipment feature in BIM 360 Build, streamlining the integration process and reducing manual effort, particularly for field workers.

Alternatively, continue using the BIM 360 Field equipment workflow until BIM 360 Build matures. Follow the 2016 lecture’s example to collect data using Field and integrate it with the model.

Linking Building Equipment with the BIM Model

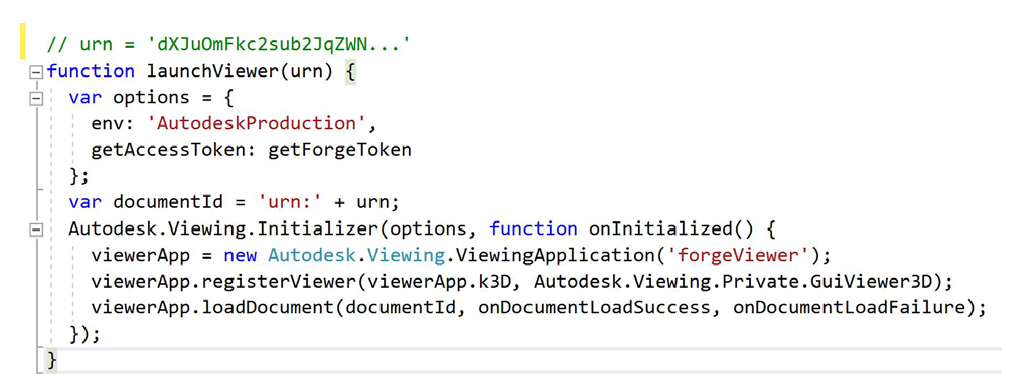

To link the equipment in BIM 360 Docs (digital model) with the equipment in the building (physical model), develop a new web application that integrates data from both realms. The new application will call BIM 360 using the following code:

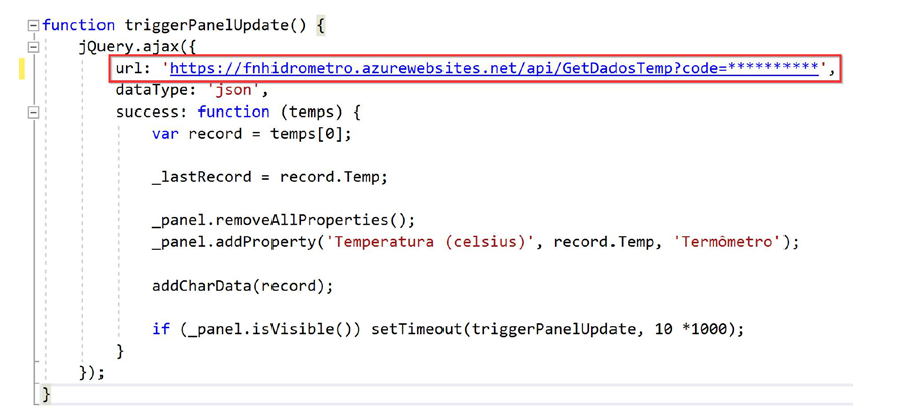

This will enable the web application to display the 3D model, complete with BIM 360 Docs’ features for model control (e.g., sectioning, zooming, model properties). Next, collect data from the sensors in the building by consuming data from Microsoft Azure IoT Hub. Here’s the coding logic:

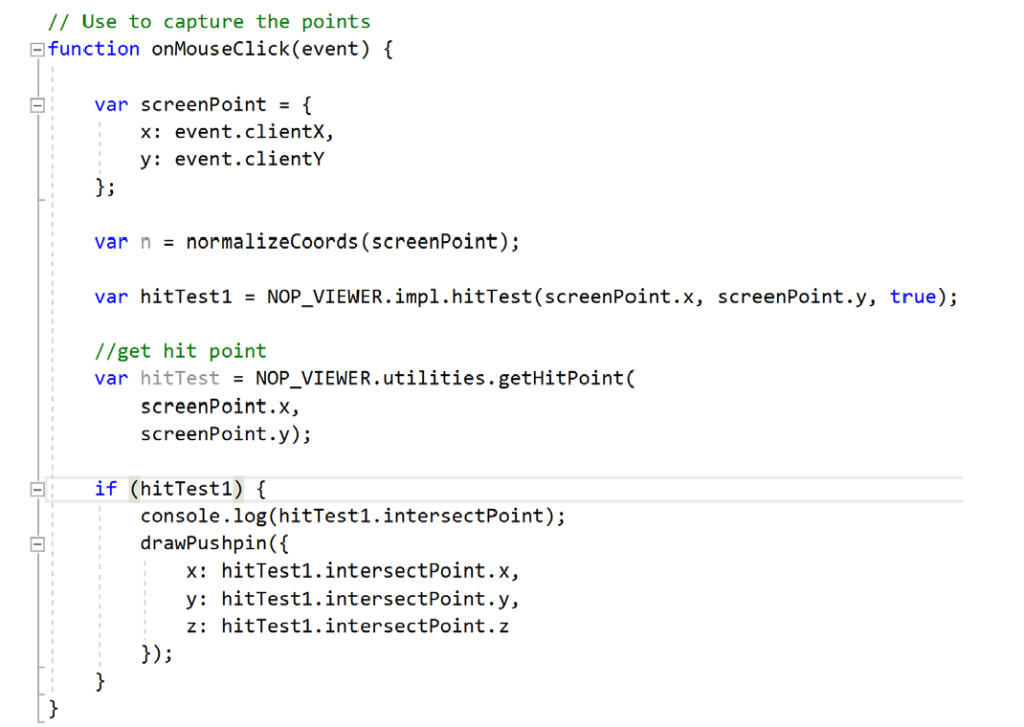

You’ll need to specify the URL where data is stored in Microsoft Azure. This will result in a web application that can consume both the 3D model and the sensor data from Microsoft Azure. To link the sensor data with the BIM model, you can create a dot above the equipment in the 3D model and connect it to the sensor data using this logic:

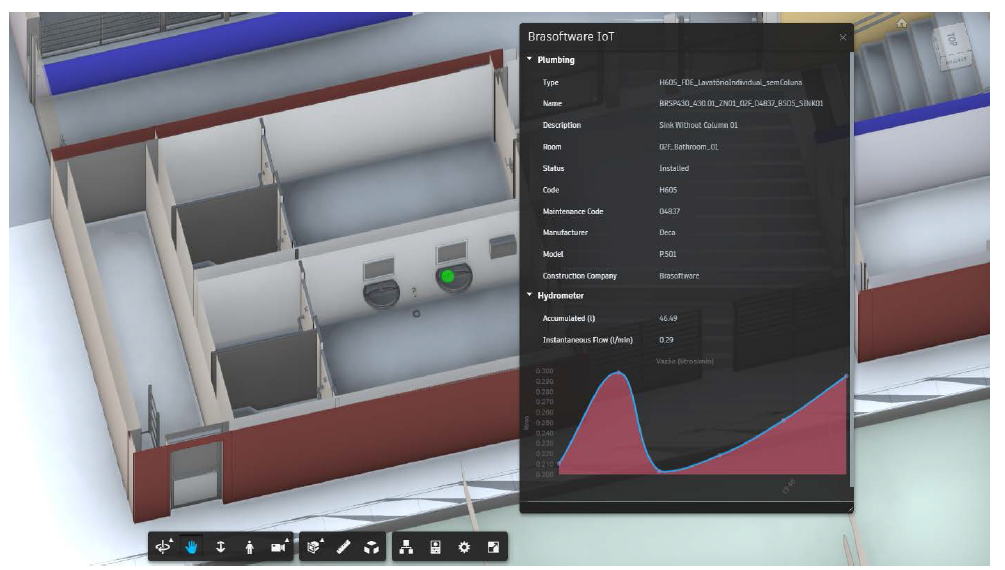

The hitTest1 will use data from “BRSP430_403.01_ZN01_02F_04837_BS05_SINK01”; resulting in something like this:

Conducting Predictive Analysis

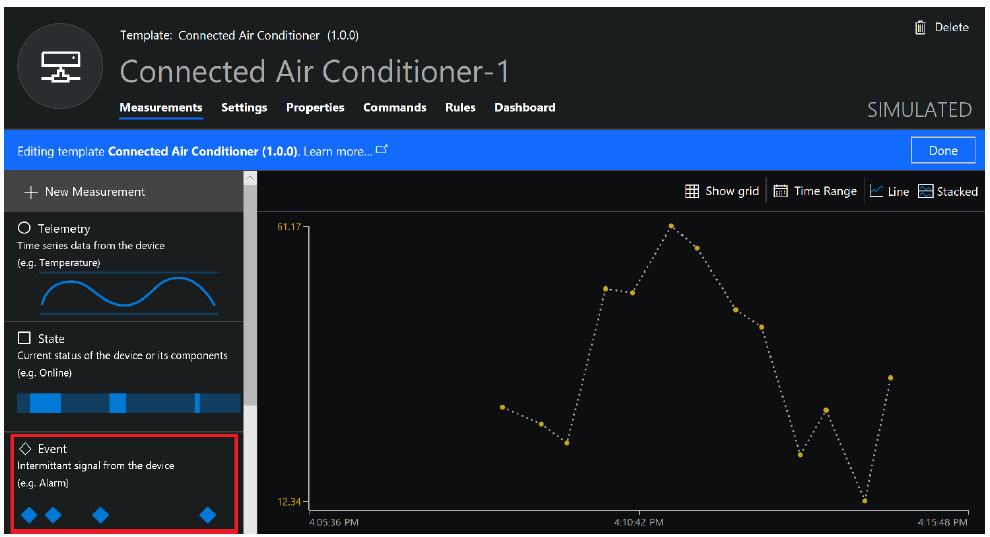

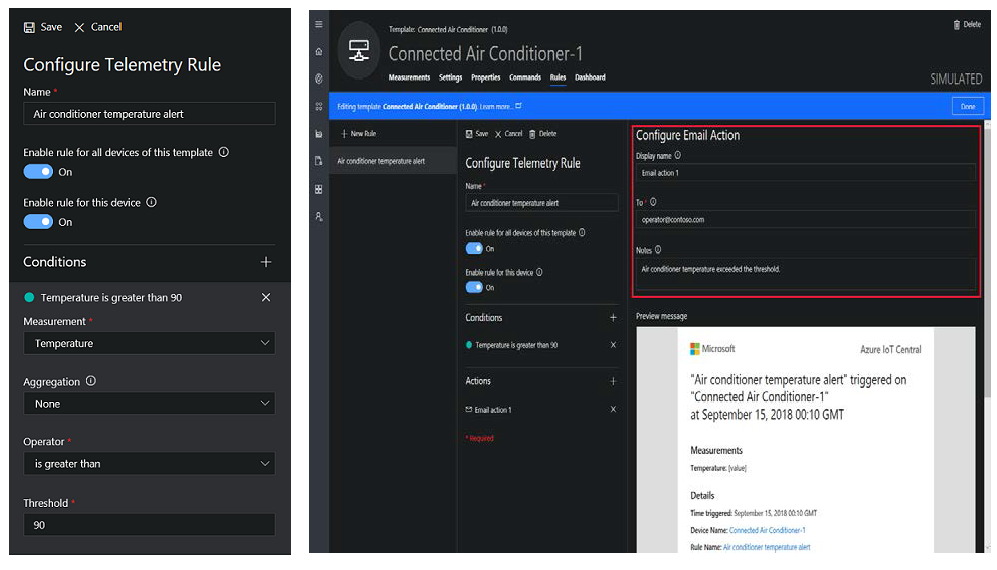

What do you want to learn from the data you collect? With this technology, the possibilities are endless. Microsoft Azure IoT Central offers a comprehensive platform to create devices, manage device portfolios, and, crucially, establish rules for predictive analysis.

This means you can analyse data trends and set up alerts for your maintenance team if something in the field deviates from the norm. Below are some examples of what Microsoft Azure IoT Central can achieve:

Conclusion

Creating a digital twin model isn’t as daunting as it might seem. However, standardising the process of collecting field data during construction, which will later be used for facility management, will take time. Start by identifying your building’s operational pain points and determine whether they can be integrated into an IoT system to enhance intelligence. Digital transformation is within reach, and all it takes to revolutionise construction is the courage to innovate and the knowledge of the technologies available today.

About the Author

Tiago Ricotta is an architect and urban planner with master’s degrees in planning and technology and business administration. A project management professional (PMP), Tiago has 14 years of experience in the AEC market and currently leads Business Development at Brasoftware Informatics. He has received several accolades, including Autodesk Brazil’s Technical Highlight Award for Creativity and Innovation. Tiago is also a certified Autodesk Revit Professional and has been a speaker at Autodesk University in Las Vegas and Brazil.

Building, Design & Construction Magazine | The Choice of Industry Professionals