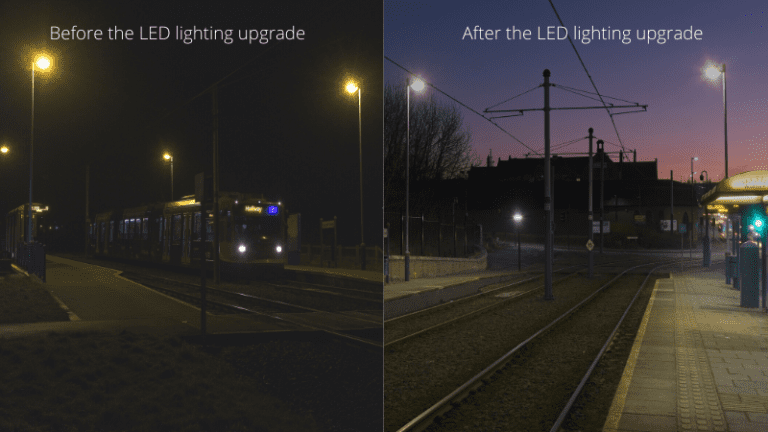

In light of the current energy crisis, Signify calls on the leaders and businesses in the UK&I region to accelerate the transition to energy-efficient connected LED lighting to help households and businesses mitigate the energy crisis. The move will also ensure quick wins in the UK’s Race to Zero. Business leaders in the United Kingdom and Ireland (UK&I) region should focus on making changes that deliver results quickly and impact both the professional and consumer lighting markets The switch to LED lighting can help the average British household save upto £250 per year, helping millions of households pushed into fuel poverty due to the change price cap in April’ 2022 In the UK’s Race to Zero, a green switch to LED lighting in the professional market could mean eliminating 3.9 million tonnes of CO2 emissions and saving a total of EUR 3.8 billion per year London – With the recent change in price cap introduced in April 2022, millions of households have been pushed into fuel poverty and several businesses are now facing added volatility due to its impact. In light of this, Signify (Euronext: LIGHT), the world leader in lighting, advocates an accelerated transition to energy-efficient connected LED lighting to help households and businesses while positively impacting the UK’s Race to Zero. With energy prices around the globe reaching all-time highs and global emissions rising at unprecedented levels, it is now more urgent than ever that businesses in UK&I lead by example and take quick action to tackle climate change. More than a decade after Signify’s call to phase out the incandescent light bulb worldwide, it now calls for the transition to energy-efficient connected LED lighting as the new standard of ‘general lighting’1. The move will help meet the goals the UK’s ten point plan and other commitments that nations have made around the world in line with the Paris Agreement. Impact for Businesses According to Signify’s findings, switching to LED lighting in the professional lighting market could reduce CO2 emissions by 3.9 million tonnes in the UK&I region, the same amount of CO2 that 175 million trees could sequester in a year. Making the switch would also save 16.1 TWh of electricity, which is equivalent to the annual electricity consumption of more than 4.3 million households. This would result in a saving of EUR 3.8 billion on electricity costs2. Upgrading to connected LED lighting3 can offer enhanced controls for better energy consumption management. Impact for households Research from the Energy Saving Trust4 indicates that lighting takes up about 11% of the average UK household electricity consumption. Our data5 suggests that after the change in the energy price cap introduced in April, switching to energy-efficient LED lighting can help the average British household save £15-£18 per light bulb, which equates to a saving of £2506 per year. Given that there are likely more lamps to replace in homes hit by fuel poverty, the positive impact would be more significant there. The switch to smart LED lighting will also pay a huge role in reducing CO2 emissions, furthering the UK&I’s progress to a greener future. The International Energy Agency (IEA) echoes Signify’s call to action. Nicholas Howarth, Senior Analyst at the International Energy Agency said “The world is facing the most significant energy crisis in recent history and energy efficiency is a solution to many of its most urgent challenges. Highlighting its importance, in June at the IEA Global Conference on Energy Efficiency, 27 governments from around the world issued the Sønderburg Action Plan calling for energy efficiency and demand side action to play a much greater role protecting households, businesses and the economy from high energy prices. This is vital for addressing the energy crisis, rising inflation and greenhouse gas emissions.” Stronger policy packages covering regulations, information and incentives will play a key role accelerating energy efficiency and related measures. This includes the deployment of smart, efficient lighting, upgrading homes with better insulation, improving the fuel efficiency of cars, as well fostering investment in new industrial machinery. Efficient lighting is a proven technology to reduce electricity demand, fast. This will also help create extra electricity capacity needed for electric heat pumps and vehicles which put upwards pressure on power demand’’ Climate Group, an international non-profit working with businesses and governments around the world to drive climate action, also aligns with Signify’s ambition.Morgan, Senior Manager, Built Environment, Climate Group, said“Climate Group is proud to work in partnership with Signify to raise awareness of the multiple benefits of energy efficient LED lighting for businesses and cities. LEDs play a key role in decarbonisation as we strive to halve emissions by 2030 and achieve net zero carbon buildings by 2050.” “The unprecedented energy savings from LEDs compared to traditional lighting presents compelling urgency to raise the priority of global LED adoption. The drive towards smart, connected LEDs can also serve as a digital platform for smart building and Internet of Things (IoT) solutions, opening up a myriad of options for businesses.” Stephen Rouatt, CEO, Signify UK&I said: “Households in the UK are now in one of the most difficult situations as they see their energy bills rise by 54%, while businesses continue to struggle as well. We understand the urgency created by the energy crisis to help families and businesses under pressure. Switching to energy-efficient LED lighting guarantees quick wins in saving money on energy bills and responding to the urgent action needed to tackle the climate crisis. After the change in the energy price cap introduced in April, switching to energy-efficient LED lighting can help the average British household save upto £250 per year (£15-£18 per light bulb). Accelerating the transition to LED lighting is one of the quickest renovations that can dramatically cut CO2 – it does not require large capital investments, has a short payback time, and can positively impact the challenge posed by the UK’s built environment and its carbon footprint.” “As leaders in the lighting sector, we have a firm commitment to transformative action and there is no better opportunity than London Climate