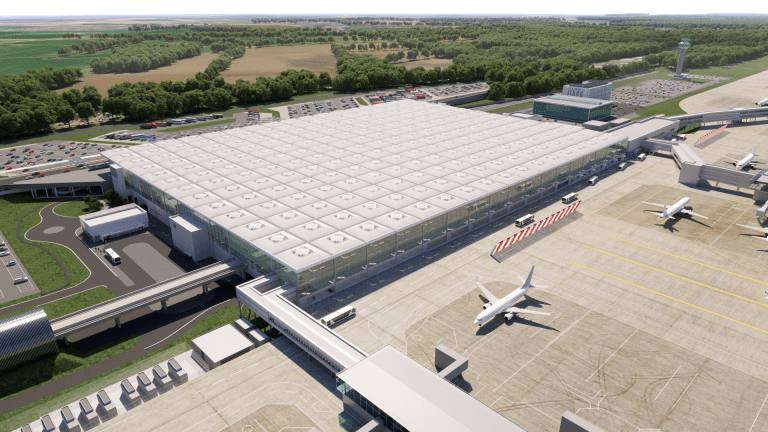

London Stansted recently revealed details of a five-year £1.1bn investment programme that will deliver wide-ranging benefits to passengers and help secure links to even more global destinations. The centrepiece of the plans is a £600m extension to the airport’s existing terminal, which will create a bright spacious environment, with more seating areas plus new shops, bars and restaurants to give travellers even more choice than they have today. The plans were first announced at the government’s International Investment Summit yesterday and follow London Stansted reporting record-breaking passenger numbers for each month in 2024. Planning permission for the extension was secured last October, and Stansted today released images and a video to showcase its plans for the first time. The terminal development will help enable the airport serve up to 43 million passengers a year, which in turn will create up to 5,000 new on-site jobs, and see the airport’s economic contribution double to £2 billion annually. Also included in the airport’s £1.1bn investment programme are a number of projects to enhance the passenger journey and support Stansted’s commitment to deliver a sustainable future, such as: In addition, a number of other projects have already been completed or underway with airport partners, including a new EV charging forecourt and drive-thru restaurants, new Emirates business lounge and new baggage reclaim carousel. Gareth Powell, London Stansted’s Managing Director, said: “Stansted is embarking on an exciting new chapter. We aim to add even more choice of airlines to continue growing our extensive route network that is valued and enjoyed by the millions of passengers who choose to fly from London Stansted every year. “We are already welcoming a record number of passengers, with people drawn to the fact we give them a great choice of destinations, at excellent value and with fantastic access into central London and the whole of the East of England. “We are unique among major airports in operating a single terminal, which means we can give people a simple, efficient and seamless experience, which we know they value, whether travelling for business, leisure or to visit friends and family. These exciting plans mean we are able to retain all those benefits, while introducing an array of new facilities and giving us the space we need to grow. “Since receiving planning permission last October, our teams have carefully considered every touch point of a passenger’s journey through the terminal to ensure the extension transforms the airport experience by adding more space, choice, comfort and range of services on offer, from check-in right through to arrivals. I believe we have successfully achieved this while maintaining the ease, simplicity and original design concept of our fantastic terminal building. “This is a really exciting time for everyone connected with Stansted as we know we have a critical role to play in serving the future capacity needs of London. Our aim is to be the airport of choice for even more passengers and we’re confident our investment plans will boost our competitiveness within the London aviation market, as well as supporting economic growth, jobs and vital international connectivity for London and the East of England.” The extension to Stansted’s terminal will add three-bays to the back of the terminal building, extending it by 16,500m2. The updated design also reveals an enlarged immigration hall moving from its current location, freeing up additional space for a bigger departure lounge plus new larger arrivals baggage carousels. The more spacious departure lounge will feature additional seating, a greater choice of shops, bars and restaurants, and a larger security hall with more security lanes equipped with next-generation scanners. The extension will also provide more state-of-the-art check-in desks plus increased baggage capacity. Stansted served a record breaking 29.3 million passengers in the year to September 2024, the busiest 12-month period in the airport’s history, and as it now enters a new phase of growth, the extended terminal will improve capacity at busy times and provide the extra space required to accommodate forecast growth. Over the past 12 months, a number of new airlines have started flying from Stansted for the first time, including Royal Jordanian and Sun Express, plus the welcome return of British Airways, boosting the number of destinations on the departure board to more than 200 this summer. Video graphics of the new extension can be viewed here. Jackie Sadek, Independent Chair of the UK Innovation Corridor, said: “This is to be welcomed with open arms. London Stansted provides vital underpinning for the current £189bn per annum GVA of the UK Innovation Corridor, and this new investment will be crucial for our shared mission to double the size of our economy by 2040. We are definitely on our way.” John Dickie, Chief Executive of BusinessLDN, said: “As a gateway to the world, London Stansted plays a critical role in welcoming visitors to London and the UK. This investment is a vote of confidence in the capital that will boost our global connectivity and enhance the experience of passengers. It will also underpin regional growth and will help us remain a world leader in the highly competitive international market.” Harriet Fear, Chair of Cambridge Ahead, said: “International connectivity is vitally important for organisations based in the innovative sectors that are so strong in the East of England, making London Stansted key to the success of the region and beyond. This significant new investment into the airport’s infrastructure, which will help create an even better experience for passengers and support the airport’s long-term route development aims, is wonderful to see.” Building, Design & Construction Magazine | The Choice of Industry Professionals