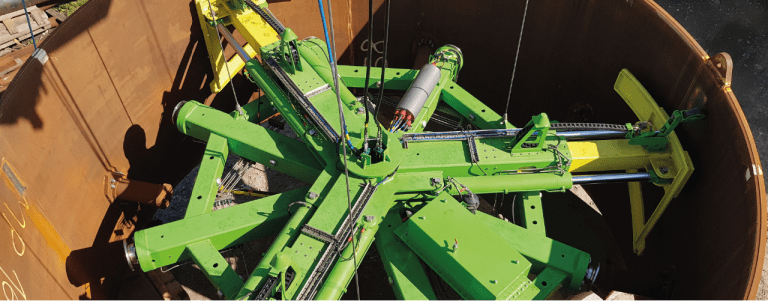

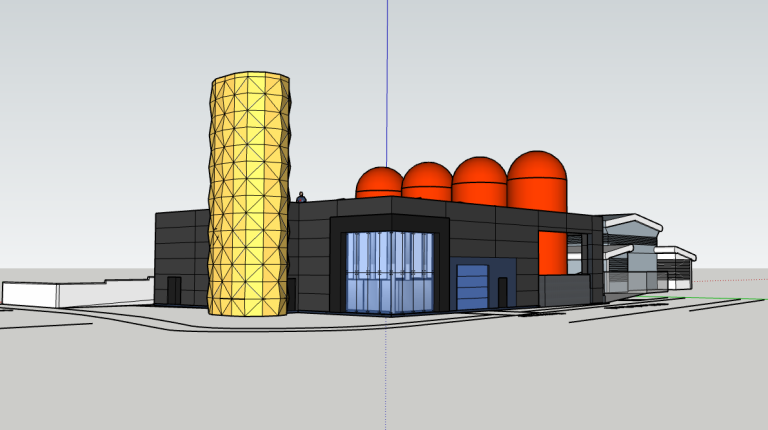

Green power replaces natural gas and coal in process heat generation (high-pressure steam, thermal oil, hot air) with the use of the power-to-heat storage Green Heat Module Together with the Solar Institute Jülich and industrial partners, Kraftanlagen Energies & Services has for the first time researched, developed and demonstrated an experimental plant operating at 1000 degrees Celsius in the multiTESS project Focus on CO2-free and base-load-capable heat and power supply from regional sources Green Heat Module The reliable and CO2-free supply of heat and electricity from regional renewable energy sources is a complex problem in industry. Kraftanlagen Energies & Services solves it as a general contractor with its new Green Heat Module (GHM) product. In order to decarbonise an even greater number of industrial processes, Kraftanlagen Energies & Services, together with the Solar Institute Jülich of Aachen University of Applied Sciences (SIJ) and consortium partners Otto Junker and Dürr Systems, developed a so-called power-to-heat storage system in the multiTESS project, which operates at a temperature level of 1000 degrees Celsius. This allows energy to be stored in the form of high-temperature heat (“loaded”) and this heat to be converted back into electricity when needed (“unloaded”). In addition, external heat sources – such as waste heat from industrial processes – can also be included. It is also conceivable to use the stored heat not only to produce electricity, but also to feed it into public district heating networks or to provide process heat for (heavy) industry. To make this possible, the test facility has now been opened in Jülich. At the opening ceremony, Oliver Krischer, Minister for the Environment and Transport of the State of North Rhine-Westphalia, said that the multiTESS technology could become a model for many residential areas as well as commercial and industrial zones. The energy supply of the future must be based on renewable energies. Jeanette Lemmes (Federal Ministry for Economic Affairs and Climate Action) affirmed that the common goal must be to ensure security of supply, prosperity and climate protection. The centrepiece of the plant in the Jülich Brainergy Park is a six-metre-high chimney extension painted bright blue. Inside are several layers of ceramic honeycomb bricks that have vertical ventilation channels. Air flows through these stones – when they are loaded, 1000-degree hot air is introduced from above, which releases its energy to the stones on its way down. When unloading, cooler air is introduced from below and flows upwards, absorbing the heat energy. The actual building houses the electric heating system, which heats the air to up to 1000 degrees, and turbines to generate electricity. CO2-free base load supply The temperature range above heat pumps – i.e. between 150 and 1000 degrees – has so far posed a major technical and economic problem for CO2-free base load supply. It is precisely this problem that is being successfully addressed for the first time at 1000 degrees in the multiTESS project. This is also the first time that an electric high-performance heater is used in conjunction with a high-temperature storage tank and heat utilisation as a complete system at a nominal temperature of 1000 degrees. The process couples the electricity sector with the heat sector. In doing so, the power-to-heat storage system enables the use of cheap but volatile renewable energies for a compellingly demand-controlled industrial heat and coupled power supply. Due to the very high efficiency, multiTESS systems can make a relevant contribution to supply security and decarbonisation in connection with renewable energies. Due to the use of existing standard components that have been used industrially for decades, multiTESS systems can already be used in industry today at lower temperatures of around 750 degrees, for example, for a CO2-free process heat supply. With parallel integration to existing heat generators, storage capacities of about 1 GWhth and thermal discharge capacities of 1 to 200 MWth can already be realised at these lower temperatures. In the future, the processes will also be operated at higher temperatures. Industry and science worked hand in hand in the planning and construction of the plant. The high-temperature heating system was designed and built by Otto Junker GmbH, Dürr Systems AG built the ceramic heat storage system and an ORC plant, and Kraftanlagen Energies und Services GmbH was responsible for the overall planning. Alfons Weber (CEO Kraftanlagen Energies & Services) sums up: “We are facing a historic turning point in industrial heat supply: Increasingly, power generation from renewable energy sources is cheaper than fossil fuels such as coal, oil and natural gas. Our Green Heat Module product takes advantage of this game change. It produces and stores process heat in a way that serves the grid, namely whenever renewables are available at a favourable price, thus enabling a CO2- and emission-free base load supply. The GHM shows a high potential for reducing fossil fuels, and thus reducing import dependencies and climate-damaging emissions, because it is available now and scalable for storage capacities of gigawatt hours.”