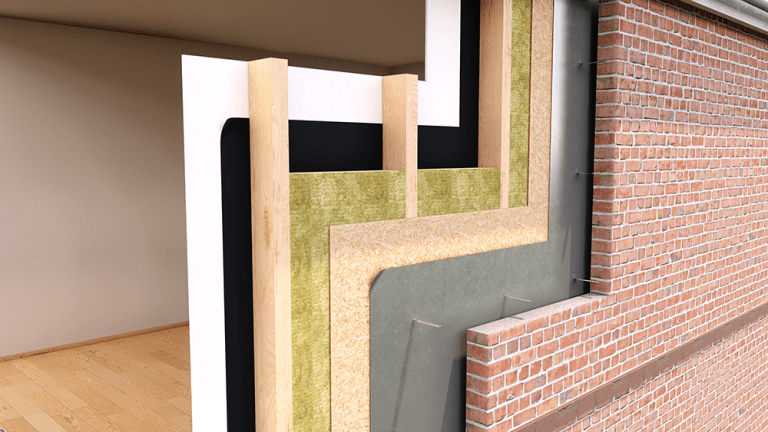

Rockwool’s new launch of NyRock technology delivers improved thermal performance, while maintaining non-combustibility and acoustic capabilities As pressure mounts on the construction industry to deliver more thermally efficient buildings whilst preserving standards of fire and acoustic performance, ROCKWOOL has launched NyRock technology. NyRock is an evolution in stone wool composition that delivers the lowest lambda stone wool insulation available in the UK. NyRock has a more efficient fibre structure to deliver low thermal conductivity Created using a new patented production process, this next generation stone wool insulation has a more efficient fibre structure that can deliver thermal conductivity as low as 0.032 W/mK. This means that U-values can be met with comparatively thinner constructions, which in the case of external wall applications, creates the potential for additional interior floor space over a given building footprint. Alongside its improved thermal efficiency, NyRock technology still delivers all the additional benefits of stone wool insulation including durability, the ability to be recycled indefinitely, and acoustic and fire performance. Comprising naturally non-combustible volcanic rock, ROCKWOOL solutions powered by NyRock technology achieve Euroclass A1 (the highest possible rating) and can withstand temperatures in excess of 1000°C. A solution to the rapidly evolving needs of the built environment Paul Barrett, head of product management at ROCKWOOL UK, commented: “Our new products featuring NyRock technology will be significant for the construction industry, giving specifiers and building owners a true solution to the rapidly evolving needs of the built environment and its biggest challenges. “To limit the impact of climate change and support the delivery of net zero carbon in the UK by 2050, it’s the responsibility of manufacturers like ourselves to go further, re-inventing and improving on existing solutions. NyRock technology does just that. “While stone wool insulation is already known for its proven benefits such as longevity, ease of install, circularity, and non-combustibility that is crucial for protecting people and properties, our patented technology builds on these advantages further. “Whether specifiers need a solution to the lower U-values of England’s new Approved Document L that also maximises floor space, or a non-combustible option for a high-rise property with enhanced thermal and acoustic performance, NyRock technology’s industry-leading lambda value for stone wool and ability to reduce the thickness of a construction element support those requirements.” NyRock technology will be rolled out across a range of ROCKWOOL insulation solutions during 2022. To register for updates on the launch of products featuring NyRock technology, visit rockwool.com/uk/nyrock or click here.