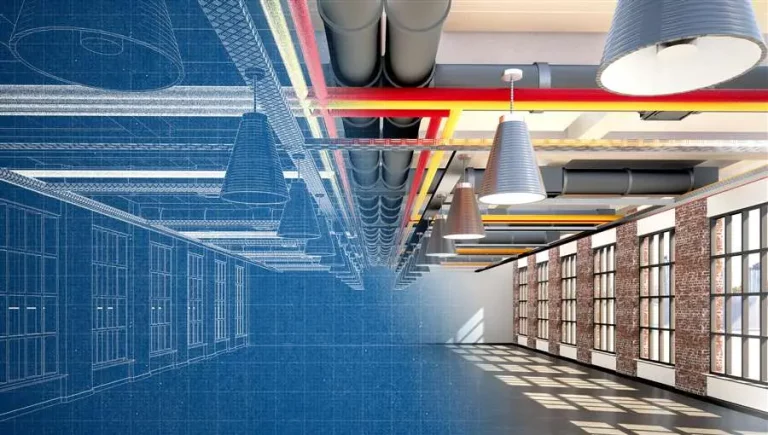

The world of building design, development, and maintenance has undergone a remarkable revolution, all thanks to recent strides in the construction industry. These breakthroughs have not only transformed how we create structures, but they’ve also ushered in a new era of enhanced productivity, efficiency, sustainability, and safety within the realm of construction. In the upcoming discussion, we’ll dive deep into the heart of these innovations that have reshaped the architecture, engineering, and construction (AEC) landscape. Building Information Modelling (BIM) Building Information Modeling (BIM) goes beyond standard 2D drawings by generating a detailed 3D model of a building’s physical features and functional qualities. This dynamic model acts as a storehouse for all project data, including architectural designs, structural systems, and even building timetables. BIM overcomes communication gaps and mitigates possible conflicts early in the project timeline by encouraging interdisciplinary cooperation and real-time data exchange, resulting in better decision-making and fewer mistakes. This virtual environment enables stakeholders to anticipate future disputes, interferences, or design inconsistencies, allowing for time and money savings. It also improves post-construction facility management, since the comprehensive model may be utilised for maintenance, restorations, and future expansions. The adoption of this has far-reaching implications for AEC marketing research; With clients increasingly seeking efficient and cost-effective solutions, construction firms equipped with BIM capabilities have a competitive edge. Marketing strategies can highlight how the collaboration leads to shorter project timelines, reduced change orders, and optimised resource allocation. 3D Printing Traditional building practises are characterised by waste of materials, long procedures, and limited architectural intricacy. 3D printing, which allows for the manufacturing of custom-shaped pieces with less waste and more precision, addresses these concerns. This approach uses a variety of materials, including concrete, polymers, metals, and composite materials, to build structures that are both practical and artistically appealing. Architects and designers may provide prospective clients a physical picture of their ideas by producing accurate physical models. This interactive experience goes beyond traditional 2D representations, allowing potential investors to comprehend the space layout, architectural aesthetics, and finer elements of a concept. As a result, decision-makers will be able to make more informed judgements based on a realistic understanding of the finished product. Trade shows, exhibitions, and presentations are all critical components of AEC’s marketing strategy. By showcasing 3D-printed models of planned projects, renovation businesses may leave a lasting impression on visitors and potential clients. The physical design of these models promotes engagement, discussion, and questions, resulting in enhanced brand exposure and economic possibilities. Drones and UAVs An aerial survey can capture construction sites swiftly and from various angles, taking high-resolution images and videos that provide an unparalleled view of the project’s development. Because it allows organisations to present ongoing projects to potential clients and investors with incredible clarity and detail, visual data becomes a helpful tool for marketing efforts. Drones can create exact topographical maps and 3D models in addition to recording visual data. These digital representations might be used in promotional materials, pitches, and web tours, providing stakeholders with an in-depth view that allows them to visualise the full product. These interactive advertising tactics help a corporation express its vision, technology capabilities, and dedication to innovation. They are also gaining popularity, and their usage in AEC market research ties in neatly with the present emphasis on greener practises. Two of the numerous advantages of employing them during construction include reduced travel time and reduced carbon emissions from fewer site visits. This aligns well with the concept of sustainable values, allowing firms to position themselves as environmentally responsible organisations. Robotics & Automation Businesses in the construction sector may use this trend in their advertising to highlight their forward-thinking culture and commitment to technological innovation. The employment of robotics and automation displays a company’s dedication to staying ahead of industry trends, which may appeal to clients seeking modern and efficient construction solutions. In marketing materials and presentations, demonstrating robotic systems in operation, as well as the benefits they give in terms of time and cost savings, might successfully attract potential consumers and other interested parties. The usage of automated technologies reflects the growing interest in green construction techniques. Marketing efforts might highlight how this optimises resource allocation, lowers waste, and encourages energy savings, while also reinforcing the company’s commitment to environmentally sensitive building practises. This technique not only appeals to environmentally conscious clientele, but it also establishes the AEC firm as an industry leader. Advanced Materials Imagine trying to sell people in a new neighbourhood where the buildings are made of self-healing concrete. This sophisticated material, capable of self-repairing minor cracks, not only protects the building’s lifetime but also appeals to potential purchasers who prioritise low maintenance requirements. AEC marketers may use this unique feature as a key selling factor in their promotional efforts, emphasizing lower repair costs and increased structural robustness. Energy efficiency is another significant component in AEC development, which is why the use of new materials is becoming more widespread. Solar panels and energy-efficient HVAC systems appeal to a growing customer sector that values lower utility costs and environmentally friendly living. AEC marketers equipped with research-backed insights can successfully communicate how these advancements translate into concrete benefits like as lower energy bills and reduced environmental impact. Summary Because of technical breakthroughs like as 3D printing, BIM, and cutting-edge project management systems, builders and engineers now have better, cheaper, and less wasteful alternatives. As these technologies improve and become more widely utilised, we may expect to see a significant shift in the building industry, paving the way for faster, safer, and more sustainable projects.