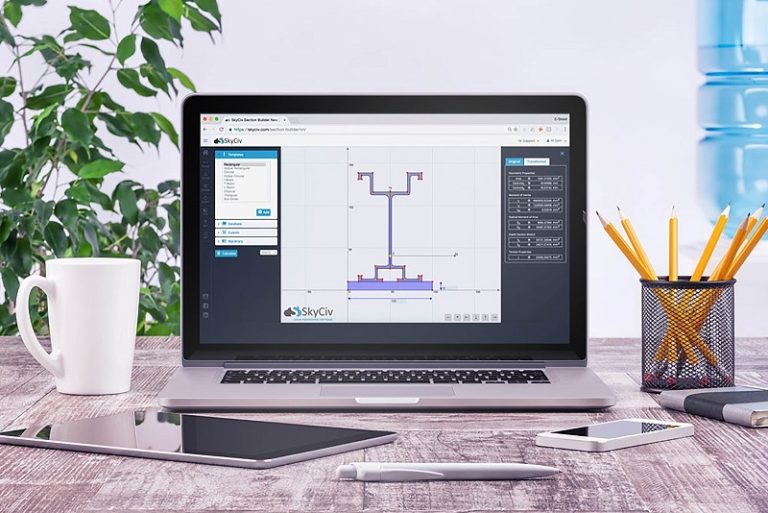

The Co-founder of SkyCiv, the structural design software provider, Sam Carigliano has been looking into the ways that Software as a Service, or SaaS, can be used to offer more. At the moment, although some people may not be familiar with the term SaaS, the software is used often. The concept offers a lot of benefits for the users including ongoing technical support. Since the global recession, which took place almost a decade ago now, there has been a significant change in the way that people purchase and consume products. For example, in the housing market the rising cost of houses has led to a significant increase in the amount of properties being rented. According to recent analysis that has come from the Pew Research Center there are currently more houses being rented in the US now than at any point since at least 1965. Renting is not a new concept but there has been a discernable shift to renting, lending and sharing goods instead of buying them. The shift to sharing products and services as opposed to owning them is now reflected in the software that is being used at the moment. The development and viability of cloud computing is a prime example of SaaS, where users pay subscription fees to use a program or a platform. This means that high quality software to individuals that would previously been unable to afford it. SkyCiv has been exploring a range of possible developments of SaaS for structural engineers. As a part of this the company’s entire suite of structural design and analysis software is cloud based. This allows the company’s specialists to view user projects and provide a more extensive troubleshooting and software problems. The cloud based operations also allow for more of a consultative support to be offered as well. With the development of the sharing economy and SaaS, it is vital that all users seek to make the most of their chosen subscriptions. For structural engineers the value of software comes from the professional consultation of specially trained experts available as well.