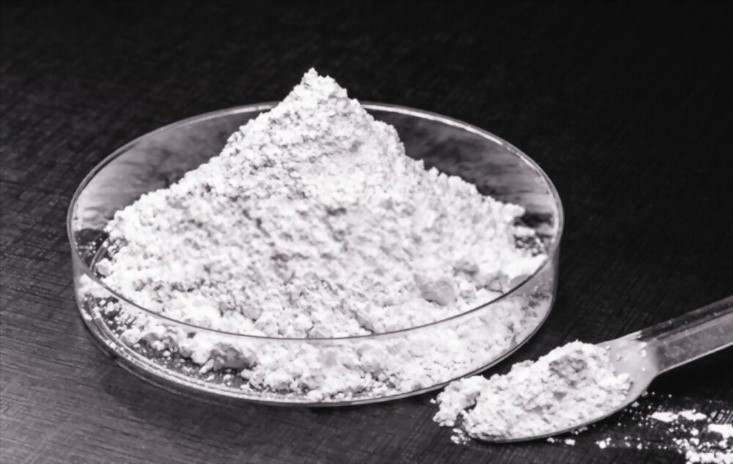

Some jobs required you to handle several materials, ranging from mild to highly toxic stuff. For instance, waste management personnel might handle harsh chemical substances. And this can pose a threat to their health and lives. However, since there are always hazards in every working environment, they are almost unavoidable. Nevertheless, businesses and industries still take some actions to prevent or reduce the effect of these dangers associated with the job. And this is why you can find fire extinguishers, warning signs, safety data sheets, and more in these firms. Also, some companies go the extra mile to organize safety training for their staff. Several industries use hydrated lime as a raw material in production. However, the colorless crystal is dangerous when improperly handled. So, companies will need a safety data sheet (SDS) for the chemical. An SDS for hydrated lime contains vital information regarding safe handling, hazards, proper disposal, threshold limits, etc. And learning more about these data sheets can help keep you safe. So, we will discuss SDS for hydrated lime in this article. Hydrated Lime Hydrated lime or Calcium Hydroxide Ca(OH)2 is a chemical substance produced in the laboratory by mixing quicklime with water or slake. And though the chemical might be dangerous, it has a wide application in several firms like food industries. Calcium Hydroxide has a chemical property that makes it less toxic when compared to other raw materials. And this makes it very useful in various aspects of food production. For instance, sugar industries use it to extract raw juice from sugar beets or sugarcane through carbonation. You can read this article to learn more about carbonation. Furthermore, hydrated lime is used in processing water for soft drinks and alcohol. In short, the chemical has several applications. However, unprotected exposure can cause rashes, skin irritation, blindness, chemical burns, or lung damage. Therefore, an SDS for this chemical is a handy tool for users. Safety Data Sheet for Hydrated Lime There is a possibility that you could come in contact with a toxic chemical substance at your workplace. And this can harm you if you are not well prepared. However, a safety data sheet can help you understand how to handle contact with such materials safely and swiftly. There are over 800 hazardous materials used in workplaces around the US. And the OSHA (Occupational Safety and Health Administration) has a database listing each of them. Furthermore, OSHA demands that every workplace have SDSs for each of the chemicals they use. This will help keep employees informed about the dangers and hazards of those chemicals and how to handle accidents that may arise during use. Hydrated lime SDS is usually found in food processing industries. It contains vital details about the chemical and how you can handle them safely. Some of what you might find in a hydrated lime SDS include. Details about the Nature of the Substance This section contains details about the physical and chemical features of the material. Due to this, it can be a bit boring to read. So, some employees skip this page and miss vital information. While reading this area seems tasking and boring for some, it contains some vital details. They include trade names, synonyms, the contact information of the manufacturer, and more. Composition and Ingredients This section explains the components and ingredients of the material. In addition, it tells how each of them behaves. This knowledge is only known to chemists, but using an SDS can enlighten you in such aspects. Physical Properties Knowing about the chemical properties alone is not enough. Understanding the physical composition of these materials and how they react with our surroundings can help us store them properly. One of the benefits of using an SDS is learning how to use, store, and dispose of hazardous chemicals. Also, the sheet shows details of the stability, reactivity, and biological implication of the material. You can read more about the physical properties of hydrated lime here: https://www.researchgate.net/. Hydrated Lime SDS Sections There are over sixteen sections in an SDS. And they each cover different details about the material. Some information you will find include handling, hazards, storage, disposal, exposure limits, manufacturer’s contact, first aid procedures, and more. The hydrated lime SDS sections include: Identification This section includes the restrictions, recommendations, and product identifier of the chemical. It also carries an emergency contact number and details of the manufacturer. Hazard Identification This contains the OSHA’s signal words, precautionary statements, and hazard statements. The section is usually updated as new hazards are discovered during classification. Chemical Composition This is the third section, and it contains the chemical names, its CAS (Chemical Abstracts Service) number, synonyms, and stabilizing additives or impurities the product contains. Also, since hydrated lime is a combination, this area will tell its exact mixing percentage, concentrations, and health hazards. First Aid Since accidents are inevitable, this section is very vital. The measures given here vary based on the impact and exposure. Fire Extinguishing Measures This section lists all the methods for fighting fire incidents caused by the product. It also contains the precautions firefighters should take while controlling the incident. Other sections include: Accidental release control Storage and handling instructions Protective control and exposure limits Chemical and physical properties Reactivity and stability Toxicological information Ecological information Disposal considerations Transport information Regulatory information Other information, like the SDS preparation date. Conclusion Working in some industries exposes you to several chemicals that might be harmful. However, learning about these dangers and steps to take during exposure can save you from worse damage or death. So, before using any chemical at your workplace, ensure you have read the safety data sheet.