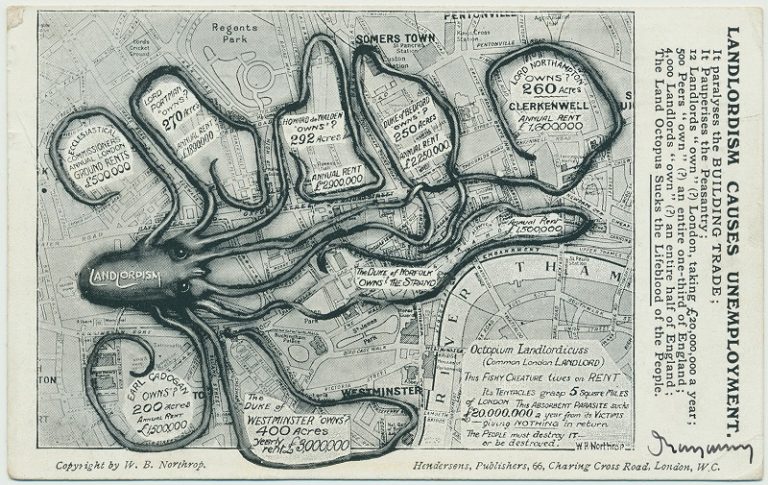

A postcard from 1909 that rails against the wealthy landlords will be offered on sale by Altea Gallery at the London Map Fair in June. William Bacot Northrop, a social justice campaigner, shows through his design the tentacles of capitalism strangling the poor tenants across Westminster, Mayfair, Belgravia and other prosperous parts. The map is accompanied by a legend that reads: “Landlordism causes unemployment. It paralyses the Building Trade; It Pauperises the Peasantry; 12 Landlords ‘own’ London, taking £20,000,000 a year; 500 Peers ‘own’ an entire one-third of England; 4,000 landlords ‘own’ an entire half of England; The Land Octopus Sucks the Lifeblood of the People.” It targeted the Ecclesiastical Commissioners (annual rents £500,000); Lord Portman (270 acres: £1,890,000); Lord Howard de Walden (292 acres: £2,900,000); the Duke of Bedford (250 acres: £2,250,000); Earl Cadogan (200 acres: £1,500,000); the Duke of Westminster (400 acres: £3,000,000); Lord Northampton (260 acres: £1,600,000); and the Duke of Norfolk (The Strand: £1,500,000). Although the postcard dates back to 1909, the situation hasn’t changed that much since. The Ecclesiastical Commissioners are known now as the Church Commissioners and they retain the freehold of Hyde Park Estate north of Bayswater Road, between Lancaster Gate and Marble Arch. Lord Portman, whose Portman Estate remains the basis of the family’s wealth, still owns 110 acres of Marylebone, while the Howard de Walden Estate now covers 92 acres, including property on Marylebone High Street and Harley Street. The Bedford Estates is the largest private landowner in Bloomsbury, including seven large squares. Cadogan Estates owns 93 acres of the Royal Borough of Kensington and Chelsea, including prime retail and residential areas in Sloane Street, Sloane Square and the King’s Road, while the Grosvenor Estate, headed by the Duke of Westminster, retains 300 acres of Mayfair and Belgravia. The Marquess of Northampton is a major landowner in Canonbury, Islington and Clerkenwell and The Duke of Norfolk still owns around 10 acres around The Strand. Altea Gallery can be found at the London Map Fair, Royal Geographical Society, 1 Kensington Gore, London SW7 2AR, on the 9th and 10th of June.