Infrastructure investment is growing across both Europe and the U.S., driven by strict environmental regulations and green construction initiatives. In the United States alone, the federal government has allocated USD 1.8 trillion in the form of tax credits, federal grants, loans, and other financial incentives. For instance, the Infrastructure Investment and Jobs Act (IIJA) provides almost $350 billion for Federal highway programs over a 5-year period (2022-2026). This is the largest infrastructure investment in American history.

As governments invest unprecedented resources to renew aging infrastructure and meet carbon reduction targets, construction professionals turn to modern materials that deliver the required performance and comply with new environmental requirements.

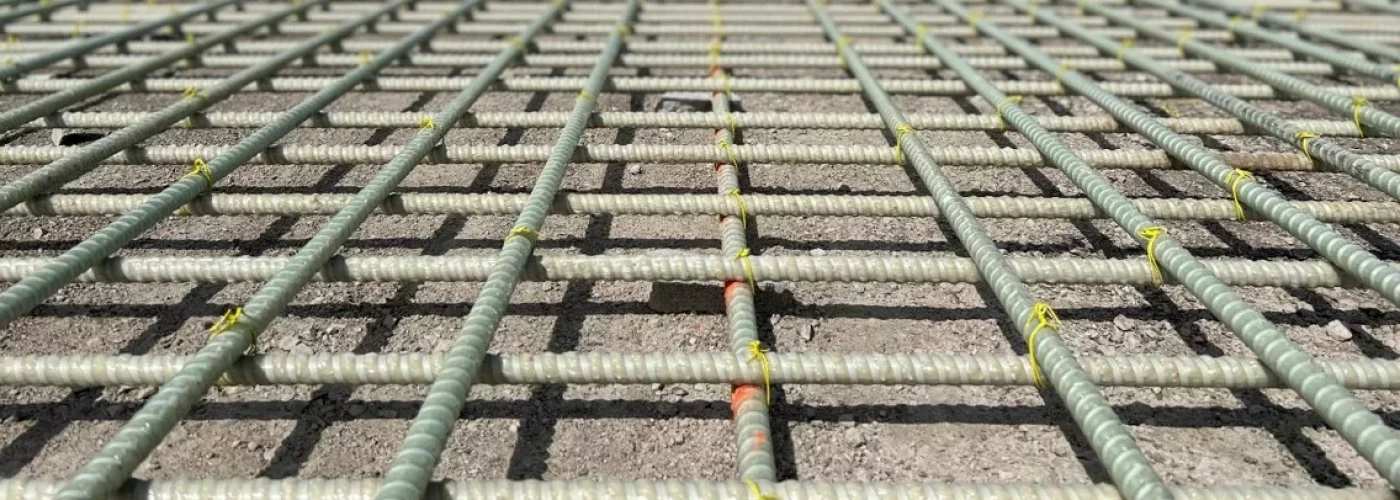

GFRP rebar represents a solution to infrastructure challenges due to its properties, such as corrosion resistance, durability in aggressive environments, and installation efficiency. The composite rebar technology transforms the entire construction industry and changes how we build lasting infrastructure across different environments, from California’s coastal highways to Europe’s mountainous regions.

The United States, Germany, Canada, and the Netherlands are among the countries leading GFRP rebar adoption: forward-thinking engineers agree that choosing GFRP rebar today means building infrastructure that serves reliably to several generations.

What Is a Fiberglass Rebar?

As the name Glass Fiber Reinforced Polymer implies, GFRP rebar is composed of glass fibers embedded in a polymer matrix. The final composite material outperforms steel in many applications due to the set of advanced properties, such as resistance to corrosion, electromagnetic neutrality, and a strength-to-weight ratio.

The use of GFRP rebar spans various infrastructure applications, including:

-

Marine structures and bridge decks;

-

Tunnels and underground facilities (parking garages) exposed to deicing salts;

-

MRI, aero-navigational, and research facilities that require non-magnetic reinforcement;

-

Highways, etc.

With a better understanding of GFRP rebar properties, the adoption of composite reinforcement expands across various construction sectors.

Top 7 Composite Rebar Advantages

The principal advantages of FRP rebar over conventional steel reinforcement have transformed the construction industry. Here is a brief review of features that make composite materials a preferred option across the construction sector.

Corrosion resistance in aggressive environments

The primary reason that bridges and tunnels deteriorate is corrosion of the steel rebar used for reinforcement. Exposed to moisture, salts, and chlorides, steel rebar corrodes and cracks the concrete. Composite rebar eliminates this weakness as it maintains structural integrity and isn’t prone to corrosion.

Example: GFRP rebar was used for the replacement of the Herbert C. Bonner Bridge in North Carolina to prevent the corrosive effect of the marine environment and extend the service life of the bridge.

Composite reinforcement was used for the barrier walls of the Champlain Bridge (Montreal) to improve the overall durability, given the FRP material’s resistance to road salts.

Lightweight facilitates efficient installation

The weight of GFRP rebar is approximately ¼ of steel rebar. The lightweight nature has a great impact on transportation logistics, installation process, and construction timelines. This leads to safer handling, lower transportation costs, and faster project completion. The lightweight is particularly valuable for remote and difficult-to-access construction sites.

Enhanced durability in extreme conditions

In severe conditions, GFRP rebar demonstrates superior service life compared to conventional steel reinforcement. Composite materials withstand chemical exposure, temperature fluctuations, freeze-thaw cycles, and other environmental stresses that cause steel deterioration.

Cost efficiency

Despite a 20-30% higher initial cost, the lifecycle cost analysis demonstrates substantial savings given the eliminated maintenance costs, longer service life, and reduced frequency of replacement.

Example: Typically, a coastal bridge requires rehabilitation every 25-35 years. This results in traffic disruption and costs millions in repairs. Composite reinforcement eliminates the need for these maintenance cycles due to the longer service life (75-100 years) and non-corrosive properties of FRP. Hence, the higher initial GFRP rebar cost is fully justified in the long run.

The key factors influencing GFRP rebar’s cost-efficiency:

-

Eliminated corrosion-related maintenance

-

Extended lifespan

-

Reduced traffic disruption and consequent economic losses

-

Lower inspection costs

Electromagnetic neutrality for specialized applications

Non-conductive and non-magnetic properties of GFRP rebar open application possibilities impossible with traditional reinforcement. The material doesn’t interfere with the performance of sensitive electronic equipment and can be used for the construction of airports and telecommunication infrastructure, research labs, MRI facilities, and subway stations.

Electromagnetic compatibility regulations across Europe and the U.S. support non-conductive reinforcement for construction projects with sensitive installations, such as diagnostic centers and navigation & communication systems. This trend drives further implementation of GFRP in urban infrastructure to ensure that electronic systems operate without interference.

Green building certification and environmental sustainability

Green building standards recognize the environmental benefits of GFRP. Construction projects that pursue BREEAM and LEED certifications can leverage GFRP rebar’s sustainability potential to achieve the certification goals.

The environmental benefits of composite materials are substantial: GFRP rebar production has much lower carbon emissions compared to steel manufacturing. Besides, rebar transportation produces a lower carbon footprint due to the lighter weight of composites: fewer vehicles and less fuel are required per project.

The material aligns with EU and U.S. federal initiatives that promote carbon reduction and sustainable construction.

Future-ready infrastructure standard

GFRP rebar has evolved from an alternative reinforcement to the preferred standard for future infrastructure. The transition reflects growing recognition of composite rebar properties that address challenges the construction sector faces.

GFRP rebar manufacturers continuously improve the technology to enhance specific properties and expand applications. Automation of GFRP rebar production lines increases efficiency and consistency and reduces costs.

Why GFRP Becomes the New Standard in Modern Infrastructure

The advantages of GFRP rebar extend beyond the composite material properties to encompass the total project value. When compared to steel, we need to consider not only the initial costs of GFRP rebar manufacturing but lifetime performance, maintenance requirements, and environmental impact.

GFRP rebar production has evolved and provided consistent quality, competitive pricing, and reliable supply chains. The industry continuously expands capacity to meet the growing demand from infrastructure projects with the priority to durability and sustainability.

Modern infrastructure requires materials that perform reliably and support environmental goals. Composite rebar meets both requirements and provides the foundation for infrastructure that can serve communities for generations. The technology that started as a steel alternative has become the intelligent choice.

Smart infrastructure investors are recognizing the opportunity in automated GFRP rebar manufacturing. Composite-Tech leads this transformation by providing turn-key solutions for rebar manufacturing to ensure efficient, consistent composite rebar production.

Contact Composite-Tech today to discover how advanced GFRP rebar production equipment can position your business at the forefront of the infrastructure transformation.