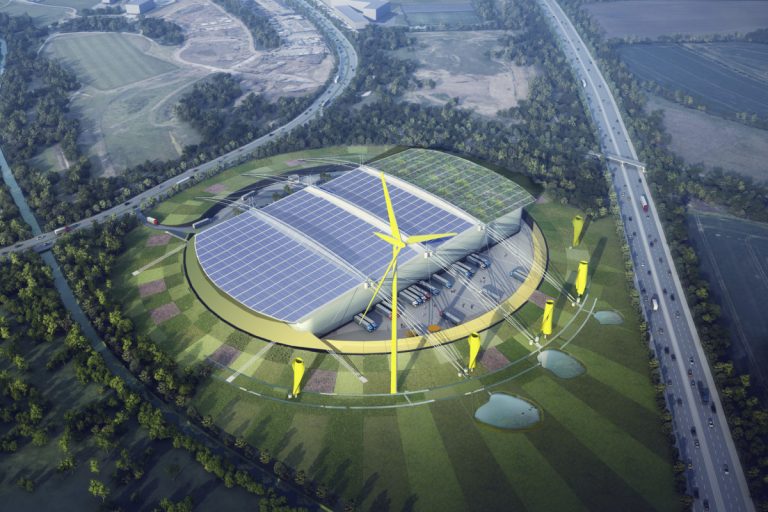

Gazeley, a leading investor and developer of logistics warehouses and distribution parks, today announces the lease of a 186,000 SQ FT unit at its Magna Park Lutterworth site to Bleckmann, a market leader in Supply Chain Management (SCM) services for the fashion and lifestyle brands. The unit has been leased on a long term lease and will serve as Bleckmann’s new distribution centre in the UK. Tornado 186 is a 186,000 SQ FT unit and has been designed to include a range of leading sustainability features, including online energy dashboards to help customers monitor energy usage, as well as rainwater harvesting and technology to optimise the use of natural light. Magna Park Lutterworth is the UK’s first and Europe’s largest dedicated logistics and distribution park. It is currently undergoing development to expand the park from 9 million SQ FT of floor space to nearly 16 million SQ FT in the coming years. Gazeley is also developing a series of new amenities, including wellness and recreation facilities as well as the new Logistics Institute of Technology (LIT). Magna Park, Lutterworth benefits from excellent transport links to the rest of the UK, with 59.3 million people, or 85% of the UK population, within a four hour drive of the development as a result of its easy access to the M1, M6 and M69 motorways. Joe Garwood, Development Director, Gazeley, said: “We are delighted to announce Bleckmann as the newest member of our customer community and look forward to growing our partnership with them in the years to come”. Situated in the heart of the “UK’s Logistics Golden Triangle”, Magna Park Lutterworth is an iconic development, ideally suited to serve the fast-expanding supply chain operations of today’s distribution companies. Four further units on our Magna Park South Lutterworth comprising 746,000 SQ FT, 300,000 SQ FT, 126,000 SQ FT and 98,000 SQ FT will be available for occupancy in Autumn 2020.”