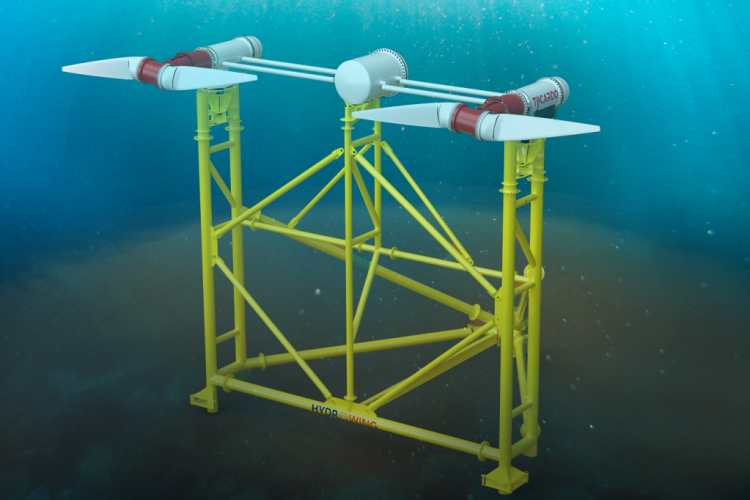

1Energy to bolster energy security and cut air pollution from buildings by 86%, project receives local support. The country’s leading low-carbon city heat network developer, 1Energy, has pledged £100m of private capital for a city-wide heat network for Derby at a high-profile event for the city’s leaders. This move follows the company securing £23m of investment into the project from the UK Government. Developed at no cost to the local community or council, the Derby Energy Network will cut city wide gas demand by around 7 per cent. It will supply the city with low-carbon heating via underground hot water pipes, using water source heat pumps to repurpose surplus heat from local businesses.1 1Energy could invest over £140m into the network as it grows.2 1Energy pledged its initial investment to the project at a high-profile event attended by Derby’s leaders, including Baggy Shanker MP, on the site of the world’s first factory late last week. The event saw the public and private sectors come together to further plans to deliver a more secure future for the city – to bolster energy security and innovation, create skilled jobs and apprenticeships, and future-proof essential infrastructure. Major organisations in the city, including Derby City Council, the Royal Derby and Florence Nightingale Hospitals, the University of Derby and Derby College, are working with 1Energy to advance the network, with plans to begin construction in 2026. The Derby Energy Network will enable the city to bolster energy security, cut costs for businesses3 and protect against sudden gas-related energy price hikes,4 with buildings being warmed by low-carbon heat rather than gas boilers. Additionally, some of Britain’s most innovative businesses, such as Rolls-Royce and SmartParc5 could soon be linked up via the project, extending the pioneering city’s leadership in the circular economy.6 Andrew Wettern, CEO of 1Energy, said: “Derby has long led the world in terms of innovation, from water networks to defence. We are delighted to bring long-term investment to the city and build on its rich industrial heritage, enabling leading businesses to play a key role in delivering a new utility model. “Home to world-renowned innovators, Derby is uniquely placed to lead the transition to a more secure energy future. Alongside transforming the city’s energy infrastructure, the Derby Energy Network will give businesses greater choice and long-term price certainty. All while unlocking economic, health and environmental benefits for the city, the region and the country. We are exciting to continue working with Derby’s trailblazers to develop the network.” As well as helping the UK achieve its energy security goals, the network will play a vital role in reducing air pollution, improving public health.7 It is projected to save around 20 tonnes of air pollutants that can cause respiratory problems8 – equivalent to taking 16,000 cars off the road for a year – by cutting pollutants from connected buildings by around 86 per cent. The network also expects to reduce carbon emissions by 19,200 tonnes through slashing emissions from buildings by up to 77 per cent. Baggy Shanker, Member of Parliament for Derby South, said: “The Derby Energy Network represents a huge opportunity for our city to deliver another cutting-edge project, continuing our long-standing leadership on innovation. By combining private capital and public investment, it will bring hundreds of millions of pounds into Derby. I see it playing a key role in boosting economic growth. “It is great to hear the project will also create hundreds of skilled local jobs, including apprenticeships. As a former apprentice myself, I know first-hand how transformative they can be.” Project fit for a ‘city of firsts’ Home to Britain’s first publicly owned water network, water-powered silk mill and planned public park, Derby has led the way in terms of devising innovative solutions to societal issues. However, heat remains one of our biggest challenges. Accounting for half the UK’s natural gas use, it is one of the main reasons our country remains reliant on imported fossil fuels and, as a result, vulnerable to sudden changes in international prices. It is also responsible for over a fifth (21 per cent) of air pollution, and 37 per cent of Britain’s total carbon emissions. Heat networks offer the lowest-cost, simplest, fastest route to addressing all these challenges at once, requiring the fewest retrofit measures.9 The Derby Energy Network provides the extra benefit of adding another element to the city’s leadership on engineering innovation. The project will also create and support hundreds of jobs, apprenticeships and supply chain opportunities locally – a key topic of discussion at last week’s event. Councilor Carmel Swan, Cabinet Member for Climate Change, Transport and Sustainability at Derby City Council, said: “This is brilliant news for our city. 1Energy’s £100m investment in low-carbon heating will mark a transformative step forward for Derby – not only in our mission to tackle climate change by cutting carbon emissions, but also in fostering healthier, more resilient communities. This initiative will help to keep homes and buildings across Derby warm in a more sustainable way whilst delivering wider benefits, from improving air quality and reducing fuel poverty, to enhancing public health and wellbeing. This initiative will be a game changer for communities across Derby, and I look forward to working closely with 1Energy to deliver lasting benefits for Derby.” Aligned with the City’s pioneering spirit, 1Energy is the first company in the UK to use funding from institutional investors to build city-scale low-carbon heat networks. The company has ambitions to deploy £1bn in the next eight years into new projects across the country, leveraging best practices gleaned from delivering the Derby Energy Network alongside Britain’s most innovative businesses. Through reducing the use of gas, these networks will help bolster energy security, protect against energy price hikes and cut costs, and reduce public health costs.10 Phil Lovell, COO at SmartParc, said: “At SmartParc, we are pleased to be working with 1Energy Group, to jointly explore opportunities to provide low carbon heat to the Derby Energy Network. Collaboration opportunities offer greater scope to harness the work we’re already doing at SmartParc for the benefit of the wider city. “By harnessing innovative technologies and shared values, we’re contributing to a cleaner, greener Derby while supporting