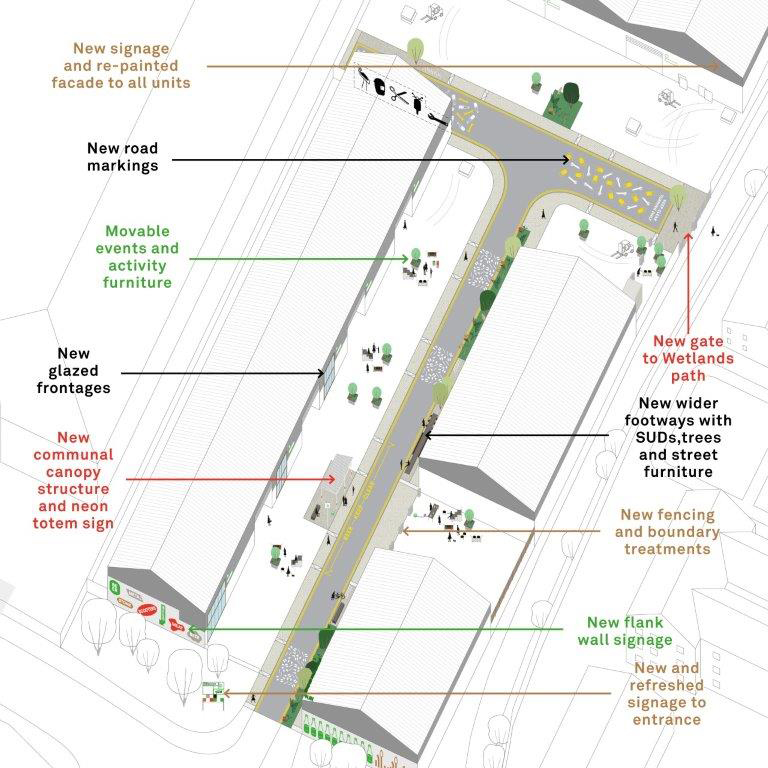

A comprehensive programme of improvement works at the Lockwood Way Industrial Estate in the London Borough of Waltham Forest has been completed and handed over by the main contractor BRAC Contracts. The £650,000 project was secured by BRAC following a competitive tender process and included improvement works to both the industrial units, as well as the surrounding public realm. Located within the Blackhorse Lane Creative Enterprise Zone, the Lockwood Way Industrial Estate is home to an eclectic mix of local businesses including two craft breweries and a vintage scooter specialist. The improvement work has been carried out not only to further increase the attractiveness of the area to new businesses, but also to improve it for those already based there. The estate now boasts attractive new frontages to the industrial units, signage for both the businesses themselves as well as the wider estate, artwork, footpath widening, fencing, landscaping, and road resurfacing. It brings to life a vision created by We Made That. BRAC’s MD, Adam Clark, comments: “As an area identified for investment, Lockwood Way possessed huge potential not only to be updated and made more attractive to current and potential tenants, but also to become a more integral part of the local community. “Through the work that we’ve delivered against the vision outlined by the team at ‘We Made That’, the estate now has the potential to offer ‘after hours’ facilities and increase its vibrancy beyond all measure! We’re delighted to have been involved in such an important project and look forward to witnessing it being enjoyed.” The transformation of Lockwood Way will be celebrated on July 16, 2022, with a family-friendly block party featuring live music, children’s activities and street food. Concluding, Councillor Ahsan Khan, Deputy Leader and Cabinet Member for Housing and Regeneration at Waltham Forest Council, comments: “Lockwood Way Industrial Estate has become a home for a broad variety of creatives, makers, and artisans who have transformed it into a bustling hub of culture and small businesses. We are delighted to have worked with We Made That and BRAC, alongside local businesses, to improve the area and build upon its heritage to support new industries finding their way and help local up-and-coming talents establish themselves. “The Lockwood Way project is an amazing opportunity to highlight the skills and services available in the borough, support local business growth and create jobs, and protect the breadth of creative diversity in the area.” Further information on the Lockwood Way Industrial Estate can be found here: https://www.walthamforest.gov.uk/regeneration-and-growth/regeneration-blackhorse-lane/regeneration-blackhorse-lane/lockwood-way