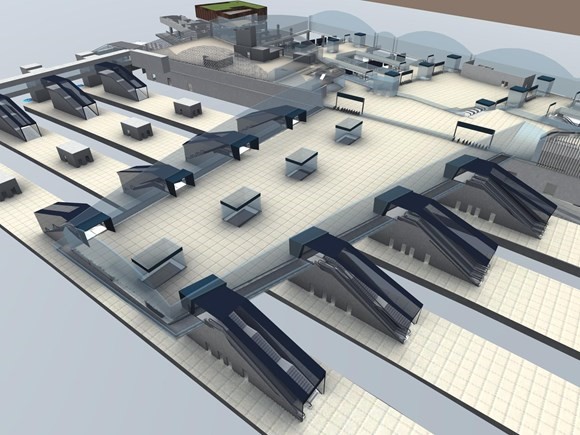

Work to install a 65-metre bridge, spanning the width of the M42, was completed in just two days and ahead of schedule as the motorway reopened to road users today (9 August) 22 hours earlier than planned. The works near Interchange Station move Solihull a step closer to the arrival of HS2, Britain’s new low carbon high speed railway. In an engineering feat led by specialist engineering contractor, Expanded and HS2 enabling works contractor, LMJV (Laing O’Rourke and J. Murphy & Sons Joint Venture), the 2,750-tonne bridge structure was carried along the motorway on a self-propelled modular transporter. The 448-wheel transporter took just one hour and 45 minutes to move the bridge span 150 metres, where it was affixed to a composite concrete deck to complete the overall bridge structure. Traditional construction methods would have required several weeks of lane closures on both carriageways, followed by additional weekend and overnight closures. HS2 CEO Mark Thurston, was joined by Andy Street, West Midlands Mayor, to observe the bridge being moved into place. Mark Thurston, HS2 Ltd’s CEO said: “This new road bridge is the first permanent structure to be installed along the route of Britain’s new railway. Today represents an important milestone for the project and the West Midlands region – which is already benefiting from thousands of jobs and renewed investment as a result of HS2. “Constructing the bridge off site and using innovative engineering practices to install it over the motorway enabled us to carry out the work in just two days, keeping disruption to a minimum for road users”. The successful installation marks the completion of the first of four bridges to be built close to the new Interchange Station. It will form part of the major remodelling of the regional road network to improve the circulation of traffic around the HS2 railway line and connect the existing road network to the new Interchange Station. Andy Street, Mayor of the West Midlands said: “Seeing major construction activity like this in Solihull is hugely encouraging as it shows HS2 is now truly underway. In just a few years, the HS2 station at Interchange and further investments in public transport will help make Solihull one of the best connected places in the UK. “Today’s work also comes at a critical time for the West Midlands, as we look to bounce back economically from the coronavirus crisis. Major infrastructure projects like HS2 have a critical role to play as they help stimulate demand and create and secure local jobs for local people”. Once complete HS2 will bring the West Midlands within an hour’s commute of Manchester, Sheffield, Leeds, York and London, making it one of the most connected parts in the country. HS2 is already transforming the region, spearheading regeneration and economic investment in Birmingham and surrounding towns, including Solihull. HS2’s Interchange station is at the heart of the UK Central Hub growth area which will create 70,000 new and safeguarded jobs, up to 5,000 new homes and 650,000 square metres of commercial space. Andrew Stephenson MP, HS2 Minister, said “The installation of this innovative bridge across the M42, ahead of schedule and with minimum disruption, demonstrates our dedication to delivering this vital rail connection to the West Midlands as efficiently and as quickly as possible. “It’s an achievement of British construction and marks another step forward in this historic project, which will leave a legacy of better connections and regional growth for generations to come”. Companies from the Midlands and the North played a leading role in the construction of the deck components and supply of the 1,130 tonnes of steel plate girders and 1,610 tonnes of precast and insitu concrete. Simon Russell, LMJV project director, said: “This is British construction, design and engineering innovation at its finest. “Major components of the bridge and its supports were built offsite under safe, high quality conditions, then transported to site for assembly. Advanced digital capabilities allowed us to design all elements of the structure in a virtual world, before building it for real, and I am delighted that the work was completed safely and ahead of schedule”. Mr Thurston and the West Midlands Mayor, Andy Street were joined by Solihull MBC leader, Councillor Ian Courts; MP for Meriden, Saqib Bhatti; Maria Machancoses, Midlands Connect Director; and Nick Brown, Chair of the Urban Growth Company. The delegation joined forces to mark the engineering milestone, recognising it as an important first step in cementing the West Midlands’ status at the heart of the HS2 network. Further work in preparation for the arrival of HS2 is scheduled to take place later this year. A similar bridge placement will be installed over the A446, ahead of two more bridge structures being installed which will span the new high-speed railway line. Over 9,000 people and 2,000 UK businesses have been part of the HS2 journey so far, and it is estimated that the project will support at least another 20,000 roles as it hits peak construction. HS2 Ltd is currently recruiting for 300 people to join the team at its flagship Birmingham office, as main construction works start in earnest this summer. For more information about HS2’s live recruitment campaign or to complete a skills match assessment visit www.hs2.org.uk/hs2-and-you/