Fusion Building Systems, the offsite designer, engineer, manufacturer and installer of light gauge steel superstructures can now provide its clients with ‘as manufactured’ digital models of their completed structures, thanks to its integration of MWF Pro Metal software from StrucSoft Solutions.

Running as an add-on to the widely-used Revit design platform, Fusion has invested in MWF Pro Metal to help its construction clients achieve the highest possible degree of accuracy in their projects and have a clear understanding of the finished structure before the offsite manufacturing process begins.

By using MWF Pro Metal, just about every element of the design for consideration can be reviewed in detail prior to sign off, then directly instructed to Fusion’s roll-forming equipment at its Northampton manufacturing facility, producing structures which are precise according to design.

Robert Clark, Fusion head of business development, said: “For offsite methods to become widely adopted by the construction industry we need to shift from a project by project approach, to one which is led by the product. BIM is the enabler for this.

“By integrating StrucSoft Solutions’ MWF Pro Metal into our design, engineering and manufacturing processes, we’re encouraging our clients to focus their attention on the overall product and in doing so, moving closer to the future of MMC.”

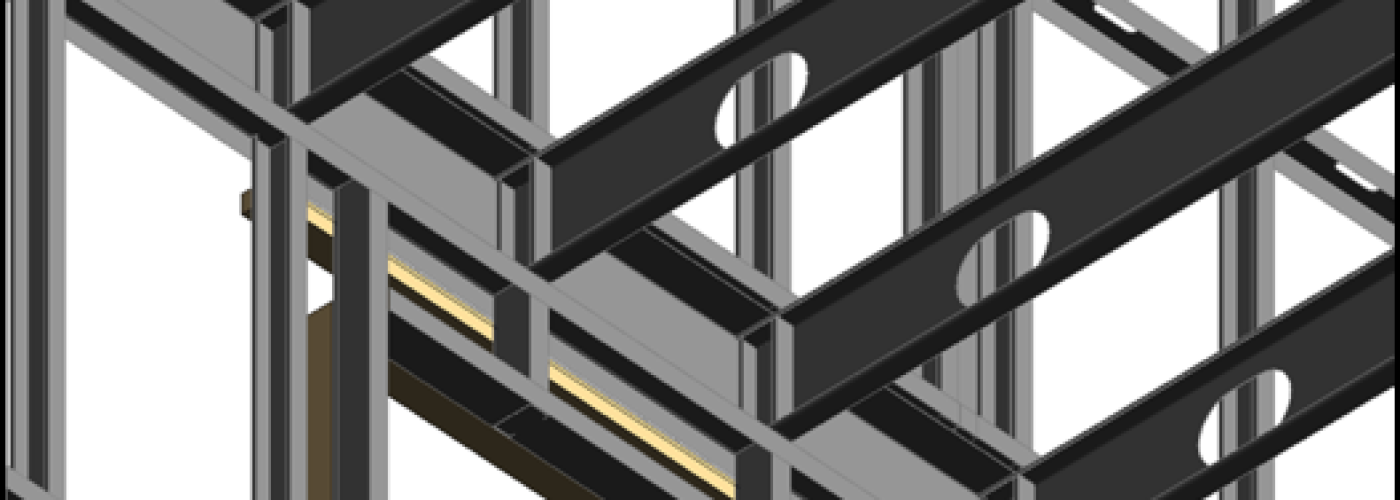

Fusion had previously been running a bespoke software solution called FusionSoft, which was ahead of its time when first developed. Now outdated and not BIM-ready, StrucSoft Solutions’ MWF Pro was chosen as Fusion’s new platform for integration with Revit and to enable the Company to work to an enviable degree of technical accuracy. Used day to day in Fusion’s design and manufacturing processes, StrucSoft Solutions’ MWF Pro Metal will enable the automated creation of walls and floors, the accurate design of cutbacks and openings around thousands of M&E locations, structural intersections and accessories, as well as allowing Fusion’s engineers to specify directly into the Revit model.

Byron Starnes, StrucSoft Solutions’ EMEA business development manager, added: “We created Fusion’s software solution just for them, tailored to the way they build and allowing them to take advantage of the most modern and up to date software solutions for their digital engineering requirements. Their investment in our product marks a revolutionary overhaul of their existing ICT solution, having an emphasis on greater design efficiencies, accuracy and collaboration – especially as it pertains to the design and manufacturing of the bespoke and patented Fusion system.”

MWF Pro Metal utilises the built-in intelligence of Revit to automate the creation of light gauge steel framing across virtually any construction project. Developed in conjunction with industry experts, MWF Pro Metal’s automated tools allow users to easily frame entire projects while simultaneously creating schedules, material cut lists, framing elevations and fully dimensioned 2D shop drawings. The tool of choice for professionals framing everything from bathroom pods, right up to billion-dollar healthcare projects.

StrucSoft Solutions provided Fusion with initial training on MWF Pro Metal at their Liverpool office and will continue to provide ongoing review work and updates as the solution matures.

For further information visit www.fusionbuild.com and www.strucsoftsolutions.com