Electrospinning is quickly becoming the future in the production of nanomaterials now a vital part of the supply chain in production and the subject of very important research into future applications.

More and more companies and research and development labs are investing in electrospinning equipment as the potential for this technology is becoming apparent and electrospinning equipment company Bioinicia, is rising to that challenge with their range of Fluidnatek products that meet a wide range of criteria. From benchtop lab machines to a pilot-scale plant, there is a machine, with potential to customize further. Here is a review of the key machines in the range.

Fluidnatek LE-10

The first in the range is the Fluidnatek LE-10, a benchtop sized tool, prefect for proof of concept development and feasibility studies.

It can fit easily into smaller lab spaces, and is great as an introductory research machine. Specification wise it is compact and lightweight, and solvent resistant for effective cleaning. It also benefits from the following:

- Touch control interface

- Coaxial electrospinning configuration

- Exchangeable rotating collectors with scanning motion emitter

- Extraction fan

- Safety interlock

- CE certified and UL compatible

Fluidnatek LE-50

Similar to the LE-10, this is a benchtop machine, however it has a lot more oomph, as powerful as an advanced research station.

It is designed to be adaptable, and to allow various configurations for when you want to go one further than proof of concept. It is also compatible with an AC to unit to allow for climate control. It is perfect for conducting precise research or development activities.Additional features include:

- Advanced electrospinning machine with hygienic design

- Touch control interface with data logging multi user-level access

- Coaxial electrospinning configuration

- Exchangeable rotating collectors with scanning motion emitter

- Optional second, independent spinning stage for processing two materials at the same time

- Compatible AC bench unit for temperature and humidity control

- Extraction fan to exhaust solvent vapours

- Safety interlock

- CE certified and UL compatible

- Machine Qualification package available to enable GMP or ISO13485 process validation

Fluidnatek LE-100

This one is for serious research and advanced R & D . It will be able to cope with even the most complex electrospinning projects. It has a large experimental chamber and wide range of optional features.

Like the LE-50 it is compatible with an AC, which makes it an ideal machine for conducting precise research, development, or small-scale production activities. Other features include:

- Ultimate control of all processing parameters

- Ultra-advanced electrospinning device with hygienic design

- Actively regulated exhaust system with pressure sensing

- Coaxial electrospinning configuration (or even tri-axial)

- Solvent resistant for effective cleaning and cleanroom compatibility

- Touch control interface with data logging multi user-level access

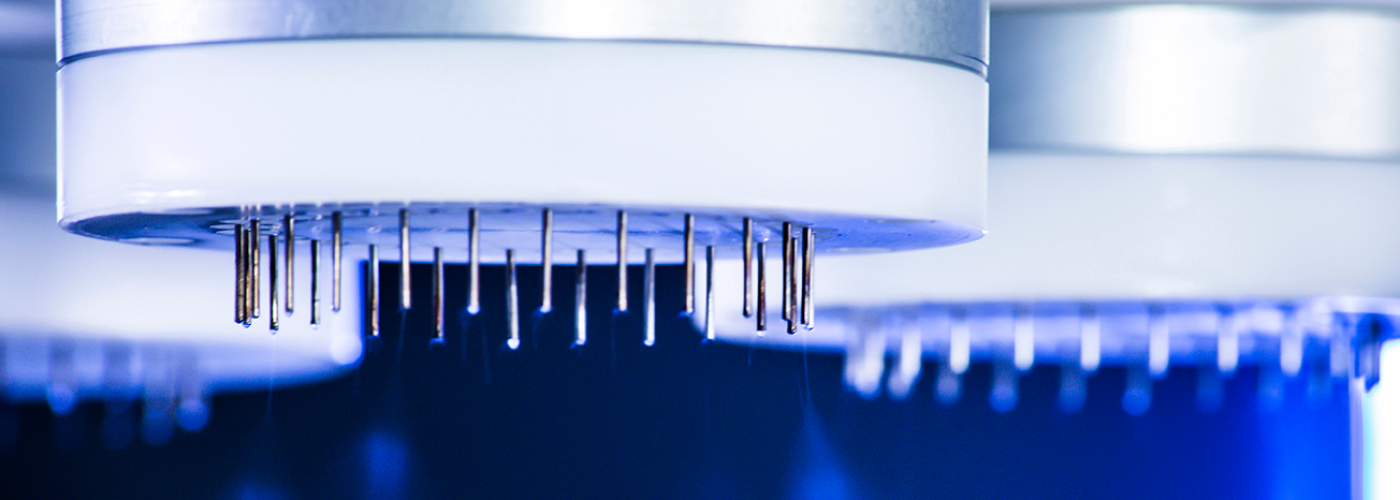

- Up to 20 emitters for increased productivity

- Programmable X, Y and Z axes motion for patterned deposition

- Exchangeable rotating collectors with scanning motion emitter

- Optional second spinning stage for processing two materials at the same time

- Safety interlock

- CE certified and UL compatible

- Machine Qualification package available to enable GMP or ISO13485 process validation

Fluidnatek LE-500

The Fluidnatek LE-500 is intended to be a pilot-line production tool that provides all of the capability needed to develop a product from initial concept to pilot-scale manufacture. It can be run either in R&D mode or in manufacturing mode. This is a serious piece of kit. Other benefits include:

- Pilot-production plant with hygienic design

- Exchangeable rotating collectors and roll-to-roll with scanning motion emitters

- Multi-emitter spinning heads for high-throughput electrospinning or electrospraying

- Configuration for coaxial electrospinning (or even tri-axial)

- Large-volume solution feeding system for extended production batches (single-phase or coaxial)

- Solvent resistant for effective cleaning and cleanroom compatibility

- Touch control interface with data logging and multi user-level access

- Compatible AC unit for temperature and humidity control

- Electrospinning apparatus equipped with actively regulated exhaust system preventing the solvent vapours to escape even with the door opened

- Safety interlock

- CE certified and UL compatible

- Machine Qualification package available to enable GMP or ISO 13485 process validation