Laser technology is more varied and versatile than you might imagine, with different solutions developed to tackle a cavalcade of use cases across the manufacturing sector.

The main choice faced by most businesses is that between CO2 laser cutters and fiber laser alternatives. If you are unfamiliar with either or both, making a decision can be tricky, so here is a quick rundown of the differences to bring you up to speed.

The perks & pitfalls of CO2 laser cutters

The main selling point of CO2 laser cutters, like those from Lotus Laser, is that they are well suited to use in conjunction with a wide variety of different materials, and so they can be put to use for a multitude of diverse applications.

Cutting, marking and engraving can be carried out on everything from organic materials such as wood and stone to artificial counterparts such as plastics, PCBs and much more besides.

Another advantage which they bring to the table, which further improves their versatility in a number of contexts, is that they are better equipped to take on thicker materials for cutting purposes, with this being carried out faster and with a smoother finish for anything over 5mm in thickness.

Last but not least, a good motivator to making use of CO2 lasers is that they have been widely used for well over three decades at this point, so the availability of experienced operators to use them and support providers to keep them up and running is second to none.

Of course CO2 laser cutters are not without their foibles, and the most significant sticking point which might give you pause is the energy costs involved in keeping them up and running. They can cost as much as 70% more than an equivalent fiber laser system to power, and that is before you even factor in the additional expenses that are necessitated by the maintenance requirements of such an assembly.

The benefits & annoyances of fiber lasers

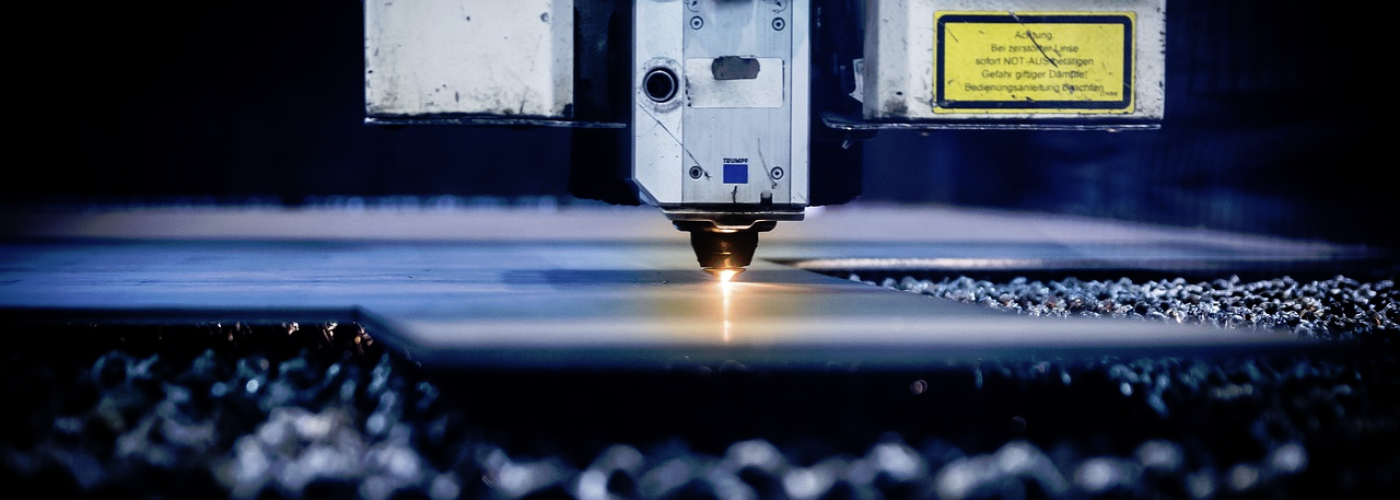

Also known as solid state lasers, cutting with a fiber laser is sensible if you are looking for speed and precision when dealing with thin, metallic materials, whether for full on cutting or simply etching and engraving. They are significantly speedier in this particular scenario than CO2 laser systems, and also have the benefit of providing a tighter focal point and a much higher intensity of laser light over this area of focus.

The result of this is that fiber lasers can cut and mark materials with accuracy and also without needing to generate any waste, or cause undue fatigue or damage to any of the material surrounding the targeted zone.

Aside from these advantages, perhaps the primary reason to pick a fiber laser solution if you are working with metals is that it will be comparatively cheap to buy and maintain in the long term, since there are fewer parts and components involved in doing the lion’s share of the work, so repairs and replacements are infrequently needed.

Another issue that users of fiber lasers will face is that while the technology is fairly well established, it is still relatively immature in terms of its development when set alongside the better known and understood CO2 laser solutions. This has an impact both on the ability to operate and deploy fiber lasers for different purposes effectively. Steps forward are being made all the time, but a CO2 laser cutter could be a better investment right now, even if fiber lasers eventually come to dominate years down the line.

Final thoughts

Any business that wants to invest in laser manufacturing equipment should weigh up their options, consider their budget and think carefully about whether CO2 or fiber laser systems make the most sense.

The good news is that with enough forethought and planning, either one could make a good addition to your production line.