With the impending Boiler Upgrade Scheme set to accelerate the UK heat pump rollout, local manufacturing and support will be key to addressing demand for remote installations, says a sector expert.

Set to launch this April, the Department for Business, Energy and Industrial Strategy’s (BEIS) flagship Boiler Upgrade Scheme (BUS) will offer homeowners grants of £5,000-£6,000 to facilitate the installation of air and ground source heat pumps. This development aligns with the Prime Minister’s earlier target of achieving 600,000 heat pump installations per year by 2028, and will drive uptake of this technology in order to achieve this goal.

However, Steve Richmond, Head of Marketing and Technical at REHAU Building Solutions, warns that immediate availability of manufactured parts will be required to meet these ambitious objectives.

“At present, around 30,000 heat pumps are installed per year in the UK,” said Steve. “In order to increase this by a factor of twenty before the end of the decade, the Government’s push for installations is going to need to be backed by a comprehensive supply chain.

“This necessitates opting for locally manufactured parts where possible in order to cut down lead times and meet the anticipated boom in demand. This extends to accessories as well as heat pumps themselves. REHAU’s RAUVITHERM pre-insulated pipe, for example, has been manufactured in Blaenau Ffestiniog, Wales, since 2012, making it the only pre-insulated PE-Xa pipe to be made in the UK.”

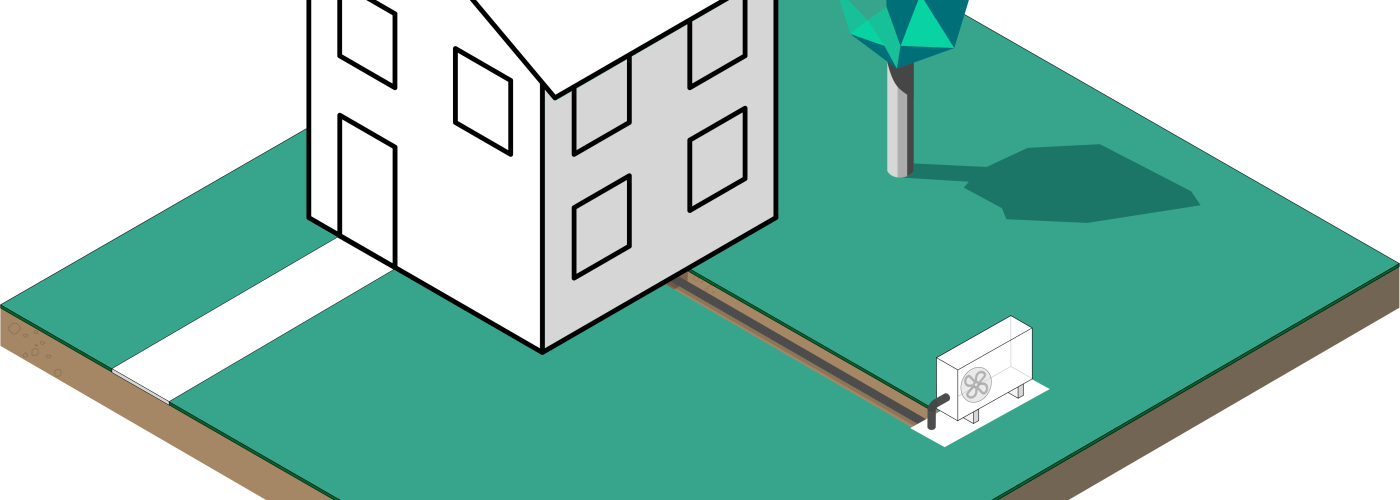

As some heat pump installations take place away from the property itself, the availability of pre-insulated pipe will be key to covering all bases in the Government’s heat pump rollout, and enabling the wider success of the Boiler Upgrade Scheme. However, Steve highlights that as each heat pump installation is unique, there is no one-size-fits-all approach to the uptake of this technology.

“It’s important to recognise that air source heat pumps are not able to be installed directly next to every property,” he explains. “This can be for a variety of reasons – heat pumps need good air flow to work effectively, and noise can also be an issue in some cases, so situating them on the side of the property is not always feasible.

“For this reason, some installations require the heat pump to be located at the end of the garden or similar. However, this must be coupled with effective pre-insulated pipe between the heat pump and the home to ensure that there are minimal thermal losses. Polymer solutions such as RAUVITHERM can address this particular concern.”

Steve concludes: “In an effort to further streamline the process of sourcing materials for remote heat pump installations, we’ve launched a dedicated landing page for installers to receive a quick quote. This tool, combined with UK manufactured parts, will be vital to ensuring an all-encompassing approach for achieving a prompt and effective transition to low-carbon heating.”

For more information on RAUVITHERM and to receive a quote, visit: www.rehau.uk/heatpumps