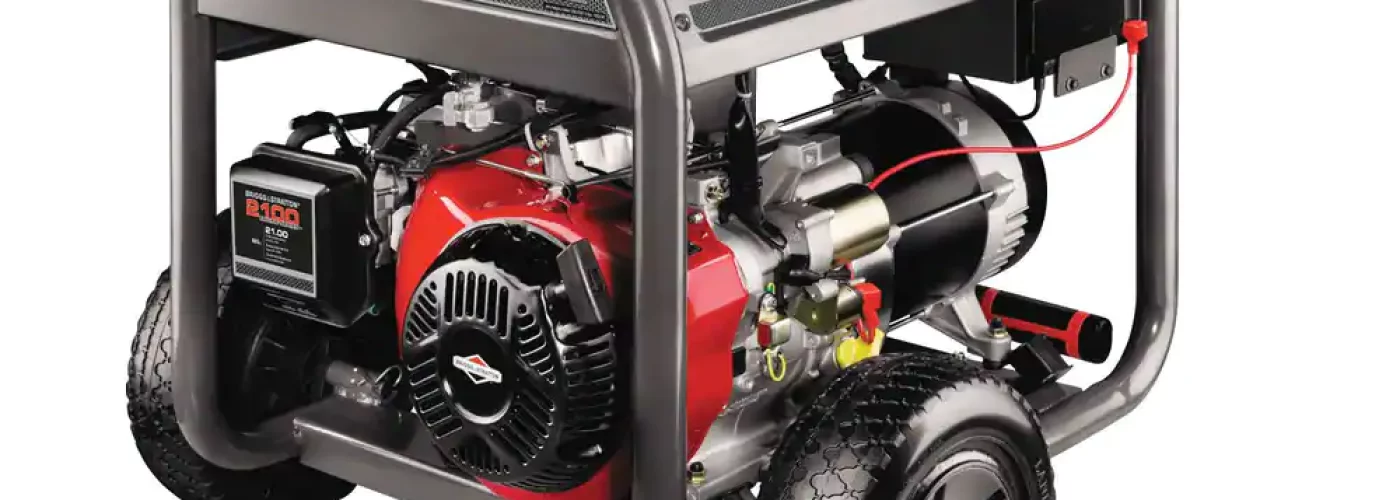

A generator that fails to start can be a nightmare scenario on any building site. There can be a whole host of reasons for a non-start to occur, but the impact can be huge. It can lead to delays on the project and hefty costs to get an emergency replacement, not to mention getting the broken generator fixed generator. If you can buy and store replacement parts for Briggs and Stratton equipment, you can have your generator back up and running in no time. Here are five common reasons why your Briggs and Stratton generator won’t start.

Check The Fuel Level

The simplest answer can be the fuel level. Check that there is enough fuel in the Briggs and Stratton generator before tearing it apart. If it is low or out completely, refill and monitor as there may be another issue that’s using all the fuel and needs addressing.

Worn Spark Plugs

A non-starting Briggs and Stratton generator can be something very simple like a worn spark plug, so this should be the first thing to check for wear and tear or damage. Examine the porcelain insulator for signs of cracks or a burnt electrode. Use a spark plug tester to determine if the plug is defective. Little or no spark indicates a defective spark plug and should be replaced.

Clogged carburettor

A carburettor can become clogged if fuel is left in the generator for long periods. As the fuel remains stagnant, some of the ingredients can evaporate and this leaves a thick and sticky substance that clogs up the carburettor and prevents the engine from starting. Clean the carburettor completely before trying again.

Blocked Air Filter

Air filters can be overlooked during preventative maintenance or forgotten about completely as time passes. A decent airflow is vital for the engine to start easily, and a blocked air filter can cause your Briggs and Stratton generator to fail to fire. The filter can be removed and washed in warm, soapy water and replaced when dry.

Low Oil Level

Some Briggs and Stratton generators have a low oil indicator, which comes on when the engine oil level drops below a pre-determined level and stops the engine. This safety method helps to prevent damage to the engine. Check the engine oil level if the red LED indicator light comes on when the recoil handle is pulled.

Create a Maintenance Schedule

Prevention is often better than cure and there are things you can do to prevent your Briggs and Stratton generator from not starting. To ensure your generators run at an optimum level, it is advisable to create a schedule. The schedule you create can depend on the environment, for example, a dusty environment may require more frequent maintenance than an outside location.

An example of a maintenance schedule can include:

- Daily: Clean debris and check engine oil and fuel levels.

- 25 hours: Clean engine air filter

- 50 hours: Check the muffler

- 100 hours: Replace engine air filter, replace the spark plugs and change the oil

Regular maintenance can help prevent many issues with your Briggs and Stratton generator, keep them running at an optimum level, and help keep your project on target.