The Association of Electrical and Mechanical Trades (AEMT) was delighted to have returned to Coventry on the evening of Thursday 23rd October for the staging of its 6th Annual Awards Ceremony. With a record number of submissions across the seven categories, this year’s programme again produced some truly exceptional entries from right across the electro-mechanical arena.

The Doubletree by Hilton, ideally situated at the M6/M69 intersection, once again played host to the gala presentation dinner, during which professional endeavour, product innovation, skills development, engineering prowess and service delivery were all acknowledged and celebrated.

Operated by the AEMT and produced by Touchwave Media, the awards programme acknowledges the skill, effort and sheer dedication of the people and businesses serving today’s complex electrical and mechanical service, maintenance, and repair sector. With sponsorship provided by a host of leading industry names, well deserved industry-wide recognition was given to those businesses and individuals that are excelling in their professional endeavours.

The 2023 AEMT Awards Winners are as follows: –

PRODUCT OF THE YEAR

Sponsored by DFA MEDIA GROUP

Menzel Motors: Pressurized Explosion Proof Motors for Zone 1

Customers that operate larger Motors in Hazardous Areas, typically refineries and chemical plants need to prevent ignitable gasses from entering operating machines. The Menzel system allows large Modular Motor operation in Zone 1 CACA or CACW, normally from 450mm frames and larger at all voltage ratings, combining Menzel’s well known flexibility, expertise, and speed of response with the requirements for Zone 1 Operation. Custom built to site requirements and highest safety standards. Highly qualified staff ensure that Menzel can respond at very short notice: With EXP systems in stock readily adaptable and deployable at short notice this is a unique feature for a medium-sized motor manufacturer such as Menzel.

PROJECT OF THE YEAR

Sponsored by EMiR SOFTWARE

MKE Engineering Group: Browndown Pumping Station

The project took place at a water utility company pumping station that was experiencing frequent tripping of equipment. Originally commissioned in the 1970’s it was in desperate need of an upgrade. Using ABB Ultra Low Harmonic drives potential issues with harmonics have been mitigated, whilst providing a clean user-friendly operating system. Feedback from the customer has been excellent, not for just the elimination of the rogue tripping but also for the sizeable energy savings.

SERVICE CENTRE OF THE YEAR

Sponsored by ABB

Avonmouth Engineering Services

Avonmouth Engineering Services’ custom built 70,000 square foot site is the largest single workshop facility for electrical and mechanical repairs in the UK. Alongside its second 20,000 square foot division in Cheltenham, the company provides an extensive range of inhouse and onsite services for the repair, overhaul, and upgrade of electromechanical technologies across the entire rotodynamic industry, with a special focus on reliability services and the pump industry.

SUPPLIER OF THE YEAR

Sponsored by MEGGER

TEC Electric Motors

TEC motors currently hold over £16 million pounds worth of Power Transmission stock in the UK, all available for immediate same day shipping; whether the requirement is a 0.09kw or a 645kw motor, a compact frame, a B56 or Brake motor, as UK’s largest independent electric motor stockist, TEC has the product. In over 18 years the company has sold over 1.5 million motors providing 24 hour, 365 days a year emergency solution to all AEMT members.

CONTRIBUTION TO SKILLS & TRAINING

Sponsored by SULZER

Ian Pattinson: The Faraday Centre

Ian, a devoted member of the Faraday Centre Limited for 23 years, began his engineering journey at English Electric, honing his expertise before transitioning to impactful roles at British Steel. Passionate about Power Distribution and Transformers, he later became a High Voltage lecturer dedicating himself to safety and education globally. Ian’s legacy encompasses exceptional teaching, consultancy, and an enduring commitment to shaping engineers and fostering a safety driven industry culture.

RISING STAR AWARD

Sponsored by TEC ELECTRIC MOTORS

Josh Bottomley: EMiR

Josh Bottomley is Team Manager for Hosted Services and EMiR Support. Josh manages a team of support engineers who provide technical and maintenance support for EMiR Software and EMiR-Cloud, the electro-mechanical industry’s leading ERP software solution. Over the last 4 years, Josh has gone from unqualified apprentice to EMiR Support Team Leader and now heads up a team of support engineers, inspiring them to perform at the highest levels and trying hard to improve our service every day.

DIVERSITY IN ENGINEERING AWARD

Sponsored by PREFORMED WINDINGS

Hidrostal: Incorporating Avonmouth Engineering Services, Bedford Pumps & Hidrostal

At Hidrostal GB, ED&I is embedded into its culture. From recruitment to career development, alongside everyday life at work, the company ensures that its employees feel supported, valued, and accommodated whatever their individual needs. As part of the UK Home Office sponsorship scheme, Hidrostal has a strong focus on wellbeing with EAP Programmes, MHFAiders and Wellness rooms onsite. Its Diversity & Equal Opportunities policy has been adopted by the AEMT as a blueprint for others.

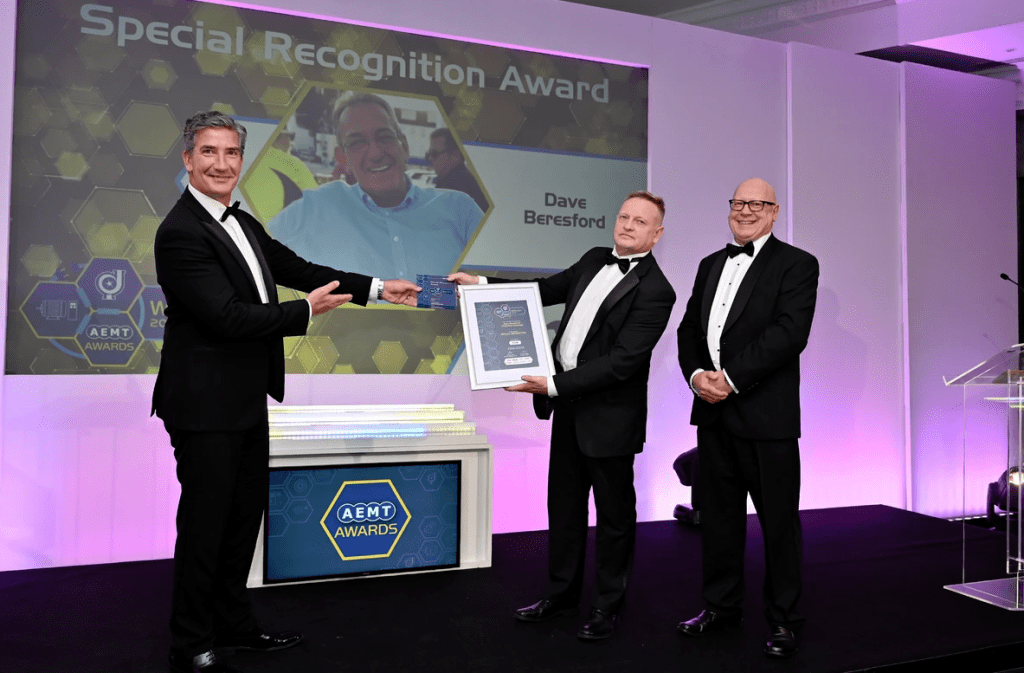

SPECIAL RECOGNITION AWARD

Sponsored by AEMT

Dave Beresford: Preformed Windings

This year, the AEMT is honoured to recognise Mr. Dave Beresford with the AEMT Special Recognition Award for his exemplary performance throughout his career. He started his career as a time served winder back in the sixties progressing to works manager and took responsibility for moving his then business to Newcastle. He has conducted various roles including technical manager, technical sales, and coil shop manager. His sense of community is highlighted by the positive connections made all over the world. Just by mentioning his name you are bound to bring a smile to those who he has worked with and known throughout the decades. His dedication to sustainability and quality has led him to innovate techniques such as press cooling and chiller insulation when forming coils. These improved processes have led to increased efficiency and reduced waste. Most of all, his enthusiasm to share knowledge and educate apprentices, colleagues and customers alike really resonated with the AEMT’s management committee. It exemplifies the values the AEMT holds true to its heart – education, community, and quality.

Commenting on the awards dinner, Thomas Marks, Secretary and General Manager at the AEMT said: “This year’s awards proved to be another remarkable success and once again provided an excellent forum through which to celebrate business and professional excellence. I very much look forward to building on that success for the 2024 programme, and to providing another superb platform for promoting the excellent work being undertaken by electromechanical service and repair sector. I would urge everyone engaged in this key part of the engineering arena, to consider the promotional value that this awards programme can deliver and ensure that your business is suitably represented.”