In the modern world, rubber surfacing receives considerable attention due to its qualities: innovation, great versatility, and undeniable durability. From playgrounds to sports halls, rubber surfacing solutions offer many key advantages, making them financially attractive for many sectors in which they can be applied. Alongside numerous benefits, rubber flooring does have certain drawbacks. In this article, we will thoroughly analyze the key advantages and existing drawbacks of rubber flooring so that you can make an informed decision about whether it is suitable for meeting your specific needs.

What is rubber surfacing?

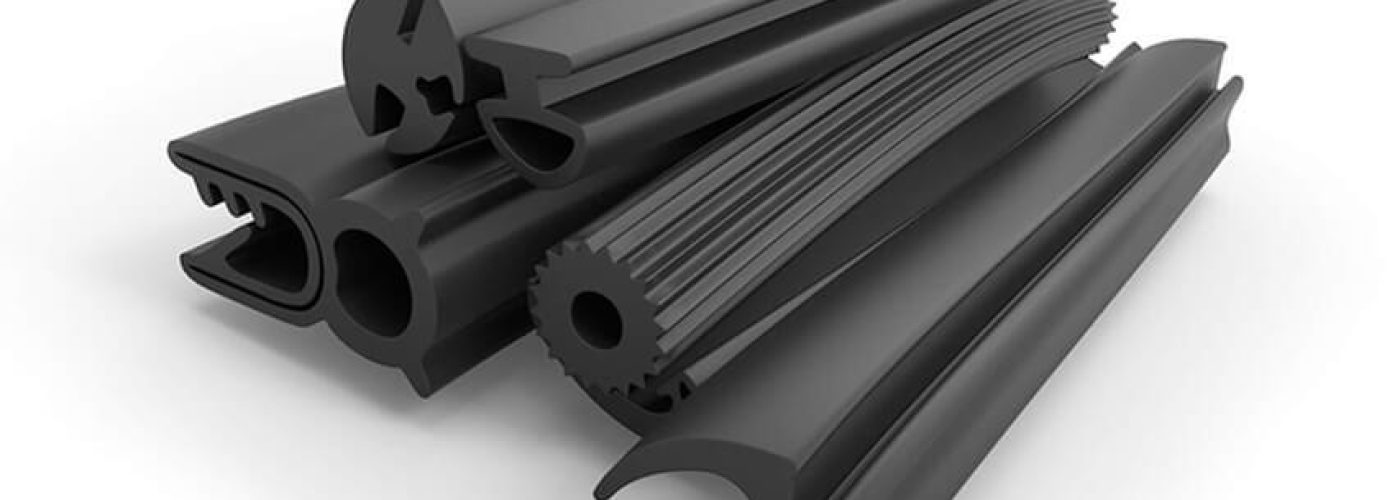

Rubber flooring is a modern type of surface made from recycled granulated rubber or synthetic rubber compounds. These materials are thoroughly mixed with a binding agent and then poured or applied onto a surface to create a seamless, elastic layer. Rubber flooring is entirely safe in terms of preventing injuries and can be used in various areas. It is durable and can withstand different weather and temperature conditions.

Rubber crumb is actively used nowadays for yards, terraces, or pedestrian pathways. Equally popular are ready-made rubber coverings. Their popularity is largely due to key rubber properties such as elasticity, slip resistance, safety, temperature resistance, durability, repairability, and ease of maintenance. Another undeniable advantage of rubber flooring over other types of coverings is the variety of available colors, making it visually more attractive and allowing for customized design solutions. Safe Step’s experienced specialists can help you choose a rubber covering that will meet all your requirements – https://safestep.pro/rubber-sidewalks/.

What is it used for?

Modern rubber flooring is used in completely different areas, including residential, commercial, and recreational areas of human activity. Let’s consider in more detail the areas of use of rubber coating:

- Playgrounds and recreational areas. Modern rubber coating is often used in playgrounds, parks, and recreation areas because it is durable, its properties allow you to reliably provide a safe and soft surface for children to play on;

- Sports halls and multifunctional fitness centers. Rubber coverings are quite a common solution in gyms and fitness centers. This cover is so popular because of its shock absorption properties that help reduce the risk of injury during training;

- Swimming pools and water parks. The rubber coating is resistant to water and various chemicals, making it an ideal solution for use in swimming pools, recreation areas, and water parks;

- Footpaths and sidewalks. Rubber coverings provide a durable and non-slip surface for pedestrians, so they are suitable for high-traffic areas.

The main benefits of a rubber surface

The basis of the rubber coating material is rubber crumb and polymer binders. The more this binder solution, the better the coating will be. The sectional rubber coating is convenient because it is easier to mount, and the sections themselves can be replaced in case of any damage or deformation. Rubber coating is a more wear-resistant solution. Advantages of rubber surfacing include enhanced safety due to its shock-absorbing properties.

Another advantage is that the rubber coating is easy to maintain. It can be cleaned with ordinary soap solution. There are also no special requirements for the installation of this type of coating. Even one person can perform these tasks. The coating can also be installed on soil, sand, asphalt, and cement. Rubber surfacing benefits extend to its durability, offering long-term protection against wear and tear.

Such a coating does not crack or deform under load. Elastic, flexible, resistant to ultraviolet radiation and low temperatures. Let’s consider the advantages of rubber coating in more detail.

1. Long-lasting flooring material

Modern rubber coating is very strong and wear-resistant, which makes it a long-lasting, financially beneficial solution. Unlike traditional materials such as wood or concrete, rubber flooring is a more versatile flooring that is less prone to cracking, bending, or warping over time.

2. Safe and non-slip

One of the main advantages of the rubber coating is its non-slip properties. The textured rubber surface provides excellent grip, reducing the risk of slipping and falling, especially on wet or over-trodden surfaces.

3. Customizable designs

Modern rubber coatings are available in a wide range of bright colors, which allows you to create many options for original designs. You can implement many of your conceived design solutions that will be creative and will match your design taste.

4. Highly versatile

Modern rubber coatings can be used on almost any surface, including concrete, asphalt, wood, and tiles. This coating is resistant to the influence of various external factors, its versatility makes the rubber coating ideal for various indoor and outdoor applications, from sports fields to swimming pools.

5. Easy to clean

Caring for a rubber surface is relatively simple compared to other materials. Modern rubber coverings can be swept, and washed with various detergents to quickly remove dirt, this is all cleaned up quickly, allowing you to keep the surface clean and hygienic with minimal effort.

6. Quick installation

Unlike traditional types of coatings that require extensive preparation and drying time, modern rubber coatings can be installed quickly and efficiently. Depending on the size of the area and the complexity of the design, rubber coverings can be ready for use in a few days.

What disadvantages of rubber coating can you find?

Rubber coating is quite popular due to its versatility, durability, favorable price, and protective qualities, but this coating also has its drawbacks. Understanding these shortcomings is important for making informed decisions about the use of rubber coatings in various areas. Despite the initial resistance, the rubber coating can deteriorate over time due to exposure to ultraviolet rays, temperature changes, and exposure to the coating of various chemicals. This can lead to cracking, peeling, or burning, reducing its effectiveness as a protective layer. The appearance of the rubber coating may not always be attractive, especially in cases where visual appeal is important. Adhering to a rubber coating can be a difficult process, especially on certain types of surfaces such as metal or plastic. Without proper surface preparation, the rubber coating may not adhere reliably, leading to premature peeling.