- STRABAG UK completes 1.2km exploratory tunnel using the drill and blast technique, a technique rarely seen in the UK tunnelling industry

- Coire Glas would be the first large scale pumped hydro storage scheme to be developed in the UK for more than 40 years

- The remote site on the banks of Loch Lochy had to be set up from scratch with all the necessary infrastructure before tunnelling could begin

STRABAG UK have completed the 1.2km long exploratory tunnel for SSE Renewables on the banks of Loch Lochy using the drill and blast technique. The multi-disciplinary team of over 100 members of staff set up a fully operational tunnel construction site in a remote location 20 miles from Fort William, Scotland in December 2022.

The exploratory works are at the site of the proposed large-scale pumped storage scheme for SSE Renewables. With a potential capacity of up to 1500MW and energy storage of around 30GWh, the Coire Glas hydro scheme would double the United Kingdom’s existing electricity storage capacity, providing homegrown renewable energy when the demand is high or if other variable generation decreases.

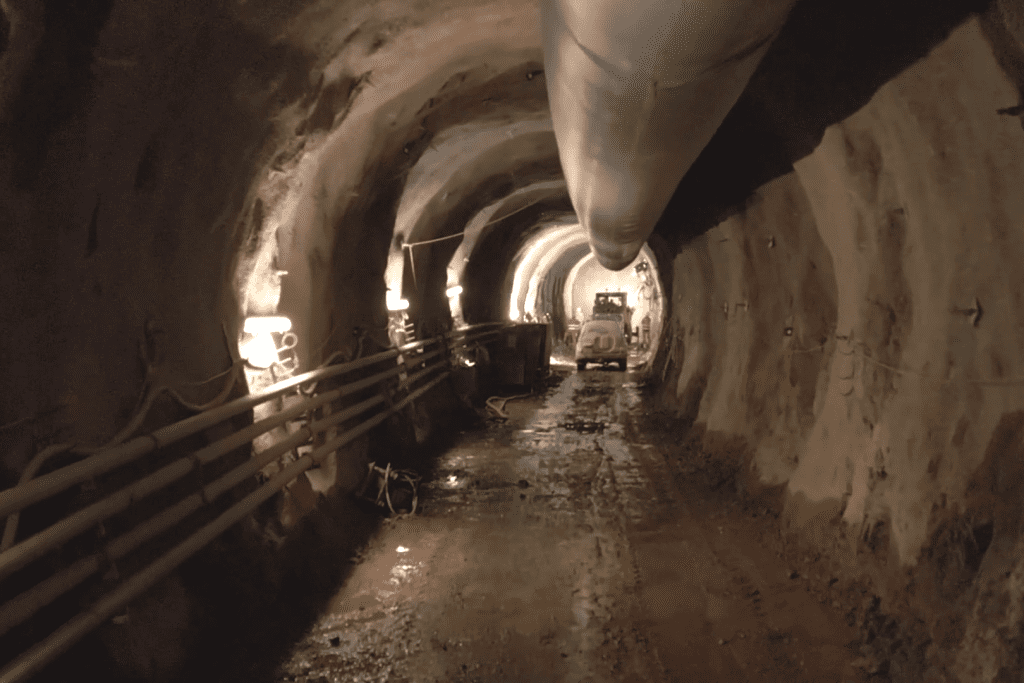

These exploratory works awarded to STRABAG UK involved the creation of a tunnel approximately 4.5 metres wide, cutting into the hillside towards the proposed location of the underground powerhouse complex, and subsequent ground investigation. The purpose of the tunnel is to acquire information on the geological conditions of the proposed location to inform the detailed design of the main works. Now that tunnelling is complete, the remaining investigation can take place over the coming months.

STRABAG UK’s experts have utilised the drill and blast technique, rarely used in the UK, to adapt to the variations in rock type and the geological conditions on site. Holes are first meticulously drilled into the rock using advanced machinery tailored to the rock’s hardness and composition, followed by blasting, where the holes are filled with explosives and detonated in a controlled manner. The blast fractures the rock, facilitating its removal and allowing for the tunnel to progress.

With works carried out in compounds surrounded by a nearby forest in the West Highlands, the steep hillside, and the shoreline of Loch Lochy, environmental protection was of paramount importance. Working collaboratively with Scottish Environment Protection Agency (SEPA) meticulous monitoring and surveillance of both tunnel effluent and noise emissions was carried out to minimise the impact on the natural environment.

The team, combining international expertise with local knowledge, work in shifts across 24 hours, seven days per week. STRABAG UK’s preference for working with local construction partners and suppliers has also created many further jobs in the region. In addition, as well as providing local schools the opportunity to visit the site, apprentices, graduates and young engineers from across the country also spent time on the site to learn about hard rock tunnelling.

Managing Director of STRABAG UK, Simon Wild said:

“We are absolutely thrilled to have completed the exploratory tunnel at the Coire Glas project. To set up a fully operational tunnel construction site from scratch with all the necessary infrastructure in such a remote location has been a huge achievement for our team. Our use of the drill and blast technique in particular demonstrates our industry leading expertise.”

Mike Seaton, Director of Development at Coire Glas for SSE Renewables, added:

“Completing the tunnelling is testament to the hard work and dedication of everyone involved and a positive step forward in de-risking the project. The works progressed to plan, and samples of the materials excavated from within the hillside are currently being analysed. The findings of the tunnelling works will be used to inform the final design, including the detailed design of underground structures, and will be a key consideration in any final decisions related to the project.”

Building, Design & Construction Magazine | The Choice of Industry Professionals