The British Safety Industry Federation (BSIF) has issued an urgent warning to those responsible for procuring personal protective equipment (PPE) and safety products following the results of its latest independent tests. These findings once again reveal the alarming prevalence of substandard—and potentially hazardous—products circulating in the market.

Between December 2023 and December 2024, the BSIF tested 161 products from non-member suppliers, assessing their advertised performance, labelling accuracy, and compliance with relevant standards. Alarmingly, only 10% (16 products) met full compliance requirements, while an overwhelming 90% (138 products) failed to meet the necessary criteria with seven test results still pending.

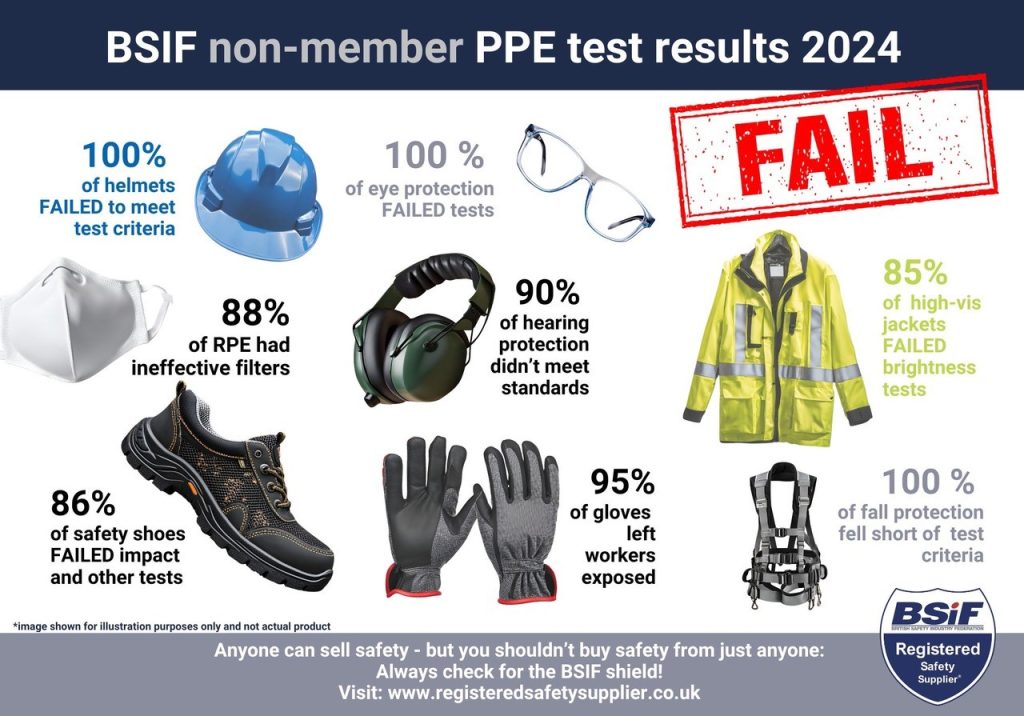

Particularly troubling was the finding that in some categories, including head protection, eye & face protection and fall protection, every non-member product tested (100%) failed the assessments. Even more concerning is the fact that many of these substandard products are still available for purchase, placing unsuspecting users at significant risk.

Key problem areas

Failures were identified across all product categories, with some showing particularly alarming issues:

• Head Protection: 100% failure rate (6 products) Products failed resistance to penetration and shock absorption tests, potentially allowing impacts to penetrate the helmet or transfer excessive force to the wearer’s head.

• Eye and Face Protection & Fall Protection: 100% failure rate (13 products) Products failed to resist particle impacts, risking severe injuries from foreign objects entering the eyes or compromising fall safety mechanisms.

• Safety Footwear: 86% failure rate (31 products) A growing number of safety shoes, often marketed on social media platforms like TikTok, promise comfort and protection but fail critical tests such as toecap compression, impact resistance, midsole penetration, slip resistance, and electrical hazard protection.

• Hearing Protection: 90% failure rate (28 products) Issues included incorrect cushion and headband pressures, compromising effectiveness against hazardous noise levels.

• Safety Gloves: 95% failure rate (21 products) Products failed claims for cut protection, abrasion resistance, and puncture resistance, leaving wearers exposed to mechanical injuries.

• Hi-Vis Clothing: 85% failure rate (11 products) Many garments lacked sufficient brightness and failed chromaticity and luminance tests, rendering them ineffective in low-visibility conditions.

• Respiratory Protective Equipment (RPE): 88% failure rate (22 products) Filters in these products did not adequately protect against hazardous dust and fumes.

The tests and assessments were conducted in accordance with the requirements of the PPE Regulation and are vital for ensuring that only safe and effective products are placed on the market.

BSIF member test results

The non-member test results are vastly different from the results of tests conducted on products supplied by BSIF Registered Safety Suppliers, who are committed to selling only certified PPE and trading honestly and ethically. Of the 399 tests completed on products from Registered Safety Suppliers between December 2023 and December 2024, 86% – 322 products – passed. Even for the 14% – 51 products – initially falling short, all issues were promptly addressed and rectified, while 24 results are still pending.

Check for the BSIF Shield

For buyers and end users seeking assurance, the BSIF Shield is a respected mark of credibility. Companies displaying this shield have pledged a binding declaration that their PPE and safety equipment meets the correct performance standards, fully complies with regulations, and bears the necessary UKCA and/or CE markings. Choosing a Registered Safety Supplier helps to ensure not only genuine products fit for purpose but also authentic information and guidance.

Commenting on the latest statistics, BSIF CEO Alan Murray says: “People are continually surprised by the sheer volume of PPE and safety products that fail to meet basic safety standards. What’s even more shocking is that, despite vendors being informed of these deficiencies, such products often remain on the market, continuing to expose unsuspecting buyers and users to significant risks.

“Our latest test results have once again brought to light a deluge of problem PPE, from substandard safety helmets to safety shoes that fall a long way short of the required standards for keeping wearers safe.

“Buyers and specifiers must urgently review their procurement processes and consider what assurances they have that the PPE and safety equipment they are being supplied with is fit for purpose.”

BSIF Registered Safety Supplier Scheme Manager Roy Wilders adds: “The findings are deeply concerning. When protective—and sometimes life-saving—equipment fails to meet standards, it’s not just a statistic; it’s a potential tragedy waiting to happen.”

“The dedicated RSSS team works tirelessly year-round, assessing members of the scheme to ensure compliance with stringent requirements and actively monitoring the market to identify and address substandard products. However, buyers also have a critical role to play. By verifying the credentials of their PPE and safety equipment suppliers, they can help eliminate the market for substandard goods and prioritise safety above all.

“Checking for the BSIF Registered Safety Supplier shield is the easiest way to ensure you only deal with compliant, competent and trustworthy suppliers. Remember, anyone can sell safety, but you shouldn’t buy safety from just anyone; always check for the BSIF shield.”

Resources for buyers

• Download the BSIF’s PPE purchasing checklist: Check Your PPE

• Find a full list of Registered Safety Suppliers: Registered Safety Supplier Scheme

Building, Design & Construction Magazine | The Choice of Industry Professionals