Plasma technology is transforming the construction industry by offering advanced surface finishing solutions that are both efficient and environmentally friendly. This innovative approach is rapidly gaining traction as a preferred method over traditional techniques.

Surface finishing is essential in construction, ensuring materials are durable and visually appealing. As the industry leans towards sustainable practices, plasma technology is emerging as a revolutionary method for enhancing surfaces. Unlike older techniques, stainless steel electropolishing provides superior results with a reduced environmental impact. This method is particularly advantageous in the context of stainless steel electropolishing, offering significant improvements in performance and sustainability.

Understanding plasma technology in surface finishing

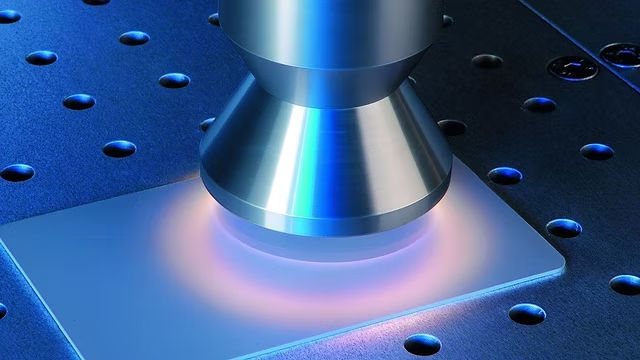

Plasma technology utilizes ionized gas to achieve precise surface finishing. This method stands out from traditional techniques like grinding or chemical polishing by delivering a smoother finish with minimal environmental consequences. Plasma technology significantly reduces waste and energy consumption, making it an attractive option for builders focused on sustainability. Traditional methods often involve harsh chemicals and labor-intensive processes, posing risks to both health and the environment.

Compared to conventional techniques, plasma technology excels in efficiency and precision. It streamlines the finishing process by eliminating the need for multiple stages, thereby reducing time and labor costs. Moreover, plasma technology’s versatility allows it to be applied to various materials, enhancing their surface properties without compromising structural integrity. This adaptability is crucial as construction projects increasingly demand customized solutions for diverse applications.

Improving construction materials with plasma applications

The use of plasma technology in construction extends beyond surface finishing, enhancing the overall performance of materials. By increasing durability and resistance to environmental factors, plasma-treated materials contribute to longer-lasting structures. This advancement is particularly beneficial in high-stress environments where materials face extreme conditions. In addition to durability, the aesthetic appeal of these materials is significantly improved, offering architects and designers greater flexibility in their projects.

Incorporating plasma technology into building design achieves more than just visual appeal. The enhanced properties of treated materials open new possibilities for innovative architectural designs that push the boundaries of modern construction. This integration aligns with trends toward sustainable building practices that prioritize efficiency and environmental responsibility.

Environmental and economic benefits of plasma technology

One of the most compelling advantages of plasma technology is its positive environmental impact. The process generates less waste compared to traditional methods, reducing pollution and conserving resources. The reduced energy consumption associated with plasma technology further enhances its sustainability credentials. This makes it an ideal choice for projects aiming to minimize their ecological footprint while maintaining high-quality standards.

Economically, adopting plasma technology translates into significant cost savings over time. With reduced maintenance requirements and longer material lifespan, you can expect lower operational costs without compromising quality. Additionally, as modern construction techniques evolve, advancements like metal deburring techniques result in even more refined finishes that enhance product value.