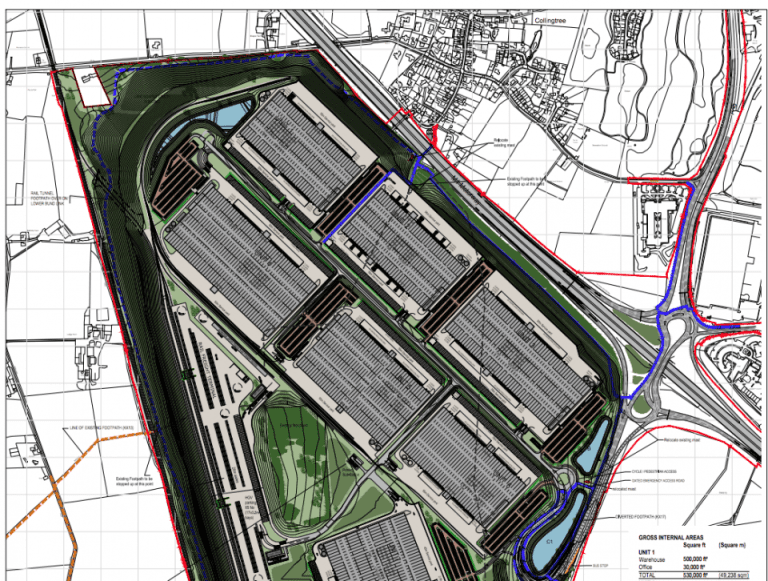

Plans for a massive Jaguar Land Rover parts distribution complex on farmland near Ashby could get the green light next week. North West Leicestershire District Council planners have recommended that councillors approve the 2.9m sq ft scheme off junction 11 of the M42, near Appleby Magna. A vote will take place at a September 3 planning meeting. West Midlands-based JLR wants to have five units on the site – including two that would be 1 million sq ft in size – to store parts prior to shipment to retailers in UK, North and South America, Europe, Africa and much of Asia. It will also act as a master site for a big distribution centre in Shanghai. JLR has not said how many jobs it would create but it would replace 10 warehouses – including main sites in Desford, Leicestershire, at Bagington in Coventry and Honeybourne, near Stratford – which employ around 1,200 staff. North West Leicestershire District Council said there had been a “significant number” of objections, including from 16 local parish councils as well as North Warwickshire Borough Council. But officers have said there was “strong evidence” of an “immediate need” for the development. They said: “Whilst concerns have been raised by objectors regarding a range of issues, the application is accompanied by an environmental statement which indicates that, subject to appropriate mitigation, these issues or other adverse environmental impacts arising from the proposed development would not indicate a conflict with the development plan as a whole, nor that planning permission ought to be refused.” There have been letters of objection about the height of the buildings and area covered by the site, the impact on the local environment, carbon emissions, the loss of farming land, light pollution and increased traffic. Hinckley and Bosworth MP David Tredinnick said he was opposing the plans along with Market Bosworth county councillor Ivan Ould and North Warwickshire MP Craig Tracey. Peter Snelson, who lives in No Man’s Heath, less than half a mile from the site, said: “Our perception is that the whole scheme is grossly out of scale with the virgin agricultural land of this area. “There will be light pollution 365 days of the year and traffic going in and out 365 days of the year. “The environmental impact will affect people living in this area for ever, no matter what IM Properties says about the wonderful lighting systems they are going to put in. “I’ve got a feeling that house prices will be affected because at the moment you look out on green fields. In two years time you will see grey sheds.” Supporters have included Kevin Harris, chairman of the Leicester and Leicestershire Enterprise Partnership. Mr Harris said: “Leicester and Leicestershire already has significant automotive and logistic strengths due to its central location and strong manufacturing base and the creation of a new global parts logistics centre would bring additional economic benefits to the area by generating new employment and supply chain opportunities for local people and businesses.” JLR would lease the site from property developer IM Properties, taking the lion’s share of 3.6 million sq ft of warehousing the developer wants to erect on the 238 acre farmland site. IM Properties has previously said the overall £350 million distribution park – with buildings ranging in size from 200,000 sq ft up to 1 million sq ft – could create up to 3,000 jobs. A Jaguar Land Rover spokeswoman said “centralising and streamlining” its UK-based global spare parts business would lead to “huge efficiencies”. She said: “This is a long-term plan. We want to start transferring operations in early 2022 with full completion by early 2023. “We will be working with current providers throughout that time to ensure a smooth transition. The new site would be operated by a third party, but it’s way too early to say who that will be. “The existing sites employ about 1,200 people between them. It’s too early to say how many the new site will have, but it’s part of the growth plans of the business, so will be a significant employer.” Asked about potential job losses at other sites and Brexit she said: “It is way too early to talk about the impact on people. “It is absolutely not Brexit related. This is a long-term project, which we began work on in early 2016. “It is absolutely not short-term Brexit planning, because it is a strategic move.” If it gets the go-ahead, work could start next spring with the first unit ready in May, 2021. Kevin Ashfield, UK development director at IM Properties, said there were “very few sites” in the UK which could deliver such a scale of development in the right location for Jaguar Land Rover. He said: “We believe the proposed planning application puts forward a high-quality, sustainable scheme will have huge economic benefits for the local area and retain an important element of the Jaguar Land Rover business in the region.”