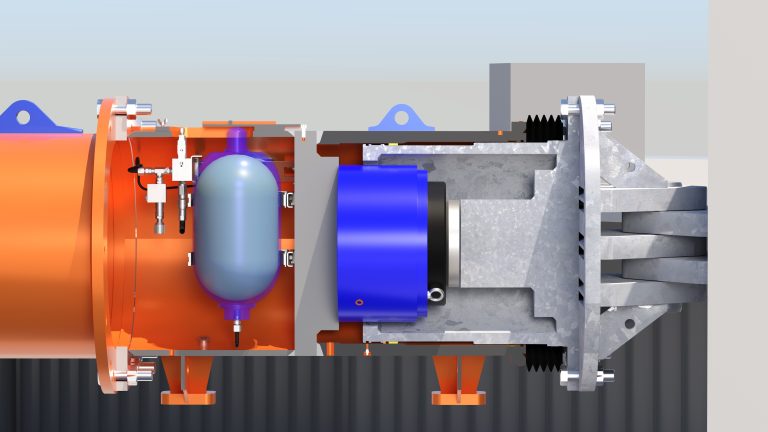

Installing a large underground concrete structure is not an unusual task for any contractor working in the water industry. Whether it’s a filtration chamber, settlement tank or storage system, installing such a structure is always a challenge. It requires a large, deep excavation support that must be made safe for people to work inside, considering ground pressure, any adverse surcharge loadings, safe access/egress and emergency procedures. Normally, once the excavation has been completed and a shoring system installed to prevent the sides collapsing inward, then the construction team can erect the formwork, pour the concrete and install any associated components such as pipework, valves or culverts. At the Mannofield Water Treatment Works near Aberdeen, contractor ESD (a joint venture between Binnies, Galliford Try and MWH Treatment) is carrying out an £8 million upgrade for Scottish Water to improve the resilience and function of the plant and ensuring a continuous supply of fresh drinking water for the city of Aberdeen. The site team is nearing the end of the first phase of the three-phase scheme, part of which has involved the construction of a large in-situ reinforced concrete access chamber below ground. This was installed in early 2023 but, due to the complex sequencing of the works, while the chamber itself was completed, the pipework serving it was not installed at the same time, creating the design dilemma of supporting adjacent existing embankments and retaining walls and exposing the structure and pipe network to be installed. So earlier this year, specialist sub-contractor CHAP Civils was appointed to excavate the soil surrounding the chamber to expose three of its four sides and create space in which ESD could carry out the pipework installation in a safe working environment. “That’s the whole complexity of it,” says CHAP Civils’ contract manager Sarah Herd. “Ideally, the shoring should have been installed and both the chamber and pipework completed at the same time. Instead, we had to excavate around the chamber and find some way of supporting the sides of the excavation while the pipework was installed.” To find a solution to this challenge, CHAP Civils worked very closely with Groundforce Shorco, the specialist ground support division of hire group Vp plc to carry out Temporary Works Design solutions for approval with main contractor ESD. “My job is basically the middle-man, the temporary works co-ordinator liaising between the main contractor and the temporary works supplier,” explains Ms Herd. “We subcontracted the support structure design to Groundforce Shorco. CHAP has worked with Groundforce Shorco several times before and although I’ve only been with CHAP for four months, I had also worked with Groundforce Shorco in my previous employment,” says Ms Herd. The excavation extended around the north, east and west sides of the chamber with support needed on all three sides, plus a section to the south. The excavation was lined with steel sheet piles and braced on two levels to the concrete structure. The longest side, to the north, measured almost 24m in length; the eastern side was 13.3m long, the southern section 6.7m long and the western side was 7m long. The irregularity of the excavation was more of a challenge than the lateral forces imposed by the retained sides of the excavation, explains Ms Herd: “The excavation was about 5.250m deep and the ground conditions were fantastic – you couldn’t have better ground conditions, really, so the lateral loads were not massive.” This was just as well because, with the concrete chamber already installed, Groundforce Shorco had to provide a bracing design that transferred the loads from the sides of the excavation to the chamber itself. Groundforce Shorco produced the temporary works design for CHAP Civils and these were passed to ESD for approval. Akil Jasm, chief engineer for Groundforce Shorco, said: “We were expecting very high loads, to be honest, but when the contractor started to dig we soon realised that the ground was better than we first thought.” “But the fact that the access chamber had already been installed made the job very challenging, so we had to find a bespoke solution which was not only safe but also provided adequate room for the installation of the pipework. Also, we needed to ensure that the integrity of the concrete chamber was not compromised due to the loads coming on to the tank from the props. Although the ground conditions were good, there were earth embankments behind the sheet piles and the sides were not self-supporting.” The design utilised Groundforce Shorco’s modular propping system. Two levels of hydraulically-adjustable Mega Brace beams were ranged along all sides of the sheet-piled excavation and the corresponding sides of the concrete chamber. These were supported by a combination of MP50, MP60 and MP150 props to brace the sides of the excavation. Mega fixed extensions were installed against the concrete chamber to uniformly spread the load on the concrete chamber rather than fixing the props directly on to the chamber. This would have subjected the chamber to high concentrated or point loads. To provide as much working room as possible, Groundforce decided to use a single prop on the eastern side, resulting in 6.7m long unsupported span. Here, Groundforce Shorco used one of its 150 tonne-capacity MP150 hydraulic props to brace the lower level of Mega Brace beams. The top of the excavation was braced with one MP50 prop – a 50 tonne-capacity unit. The rest of the excavation was braced with 10 MP60 props – three pairs along the north side and the other two pairs to the western side. Groundforce Shorco used KD6 overlapping steel sheets to line most of the excavation but those along the western side were interlocking GFI sheet piles. The western side of the excavation was open-ended and too narrow to close the end. Therefore, there was risk of lateral movement of the Mega Beam on the western side. Hence why it required interlocking sheet piles and to weld the beam to the piles. Because they are interlocking, the GFI sheets