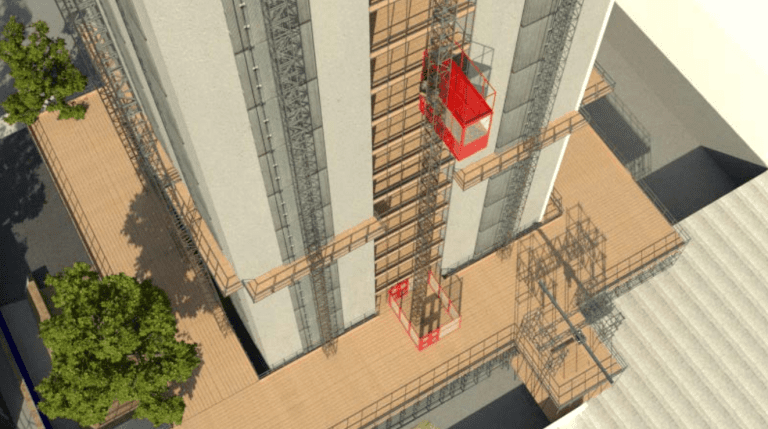

By crafting tailor-made solutions like a 21-metre Table Lifting System, Doka caters customers’ specific needs and boosts the efficient construction of the second highest building in Detroit. Doka is playing a key role in shaping tomorrow’s Detroit today by acting as an all-in-one supplier for the 209-metre (685-ft.) skyscraper and providing one of the fastest self-climbing formwork solutions on the US market. The Hudson’s Site project is a mixed-use development located in downtown Detroit, Michigan, USA. The project includes two buildings: a 209 meter (685-ft.) high-rise tower and a 70 meter (232-ft) mid-rise building separated by a through-cut. The tower will house modern offices, event venues, high-tech residences, and a luxurious 5-star hotel. It is expected to be completed in 2024 and will be the second tallest building in Detroit after the Renaissance Center. Experts are expressing high anticipation for this project, considering it a potential game-changer for the city. The Hudson’s Site project on Woodward Avenue is considered a bold and even iconic project. Its scale, prime location and the rich history of the neighborhood make it a colossal undertaking. Doka’s role in crafting a 49-storey masterpieceTo meet the special requirements of the project with limited on-site space in this urban area of Detroit, Doka developed a key to eliminating the need for traditional crane lifts between level-to-level transitions. Doka’s engineers came up with a self-climbing Table Lifting System solution, spanning a total of 21-metres (68,9-ft.) that is exclusively designed to lift slab formwork across six levels of the Hudson’s Site Tower. The hydraulic Table Lifting System not only increases efficiency by strongly improving the speed of material hoisting but also helps ensure safety – a paramount aspect in every Doka endeavour. Additionally, the adaptability of Doka’s Framed formwork Frami S Xlife system proved essential in navigating the project’s 112 different column cross-sections. Brian Gulick, Superintendent with Barton Malow, recognizes Doka’s professional support, saying: “It was crucial for us to have Doka on board. Doka’s personalized Table Lifting System enabled us to operate the construction site without the use of crane lifts between level-to-level transitions, which helped us to optimize construction speed.” Doka’s cutting-edge BIM Revit model is designed to analyse potential suspension points of the climbing systems of the core and slabs and to detect and prevent possible clashes on site by re-coordinating the schedule in advance. Doka ensured early on that the right solutions were in place for this complex project by collaborating closely with all stakeholders, which enabled the project to stay on track and meet its ambitious schedule. Global expertise, local precision in engineeringDoka’s engineering services for the Hudson’s Site project epitomize the global fusion of expertise of the engineers in the Austrian headquarters and the Doka team in the US. This dual approach ensures that the project benefits from cutting-edge solutions provided by Doka that are tailored to meet the specific demands of the local construction environment in Detroit. Doka’s engineers faced further challenges, such as providing the right formwork solutions for the skyscraper’s unequally-shaped core. Doka crafted a custom-made formwork solution featuring the large-area formwork Top 50, and the Super Climber SCP, which is recognized as one of the fastest self-climbing formwork solutions on the US market. A mini crane mounted at the top level of the Super Climber, supported the installation of heavy steel embeds, which significantly reduced the crane’s period of use. This tailored solution achieved an average five-day cycle time instead of the usual seven-day cycle time, resulting in significant acceleration of the construction while increasing efficiency and safety. What’s more, an integrated concrete placing boom facilitated the concrete pouring of the core, slabs and columns. A self-climbing Xclimb 60 Protection screen was designed for slab edge protection, as were several screens with integrated storage platforms as an extra feature. Project: Hudson’s Site TowerLocation: 1200 Block of Woodward Ave – Detroit, MIType of structure:High Rise, Residential & CommercialHeight: 209 m (685 ft.)Storeys: 49Developer: BedrockGeneral Contractor:Barton Malow CompaniesConcrete Contractor:Downtown Concrete Partners (JV between Barton Malow Concrete & The Colasanti Companies)Architect: SHoP ArchitectsStart of construction: 2017Overall completion: 2024Cycle time: 5 daysSq. Ft: 1,500,000 ft2 Products used:Core: Super Climber Platform SCP, Large-area formwork Top 50 SFacade: Xclimb 60 Protection Screen with integrated storage platforms & stair towers, self-climbing Table Lifting SystemSlabs & Shoring: Dokamatic S Table, 10k Shoring, SuperDekWalls & Columns: Framed formwork Frami S XlifeServices provided: DokaCAD 9 for AutoCAD, DokaCAD 9 for Revit, BIM with Doka, Doka Manuals, Engineering and Pre-Assembly Building, Design & Construction Magazine | The Choice of Industry Professionals