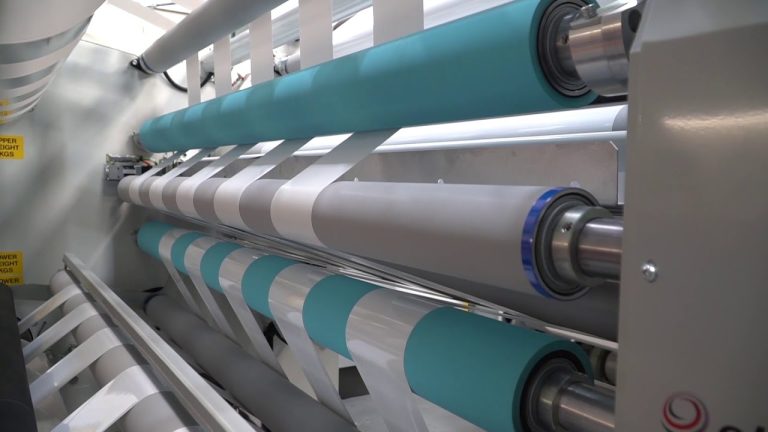

A slitter rewinder is a machine used in the converting industry. The converting industry is an important part of manufacturing, and it’s especially relevant right now, as the U.S. is working to promote more onshoring of manufacturing and similar work. The following is a guide to the converting industry and what the implications are, as well as more specifics about the slitter rewinder, also just known as a slitter. 1. The Converting Industry The term converting industry refers to manufacturing processes and practices that are used to process materials that come in thin layer form. Thin layer-formed materials can include textiles, paper, foil, plastic film, and materials that aren’t woven. The materials are usually stored and then shipped in their roll form after being wound. A roll of shipped materials can be just a few inches in diameter, or these materials can be many feet. The material width can be a fraction of an inch to several feet wide. Converting processes include painting, coating, and laminating. Other converting processes include slitting, which means making narrow rolls from wider roles, drying, die cutting, packaging, and extruding. The processes can go from very slow speeds to high speeds of thousands of feet per minute. The processes can be high-tech and sophisticated, and they’re often pretty customized. A material roll is usually unwound from its roll form in one layer, then they’re processed and rewound into a roll so it can be shipped or processed further. The single material layer is the web that flows through machines or a process. Basically, the term converting in converting industry means a roll of material is processed and then converted into a roll of something else. 2. Web Handling Web handling is the engineering, equipment, and science that’s needed to bring flexible materials through the different required converting processes. The right kind of web handling, which can be done through the use of the right designed, engineered, and manufactured equipment, can make sure that webs are transported through their converting processes without any defects. 3. The Role of a Slitter Rewinder Slitter rewinders are used for some essential functions that help make the modern soft materials we know today. Slitter rewinders are machines that cut what’s known as a parent or master roll of material to a width that’s smaller. The materials need to be cut smaller so they can go on to the next step in the production process. A slitter rewinder is a piece of equipment that’s found in a wide range of manufacturing facilities across many global industries. The majority of these pieces of machinery are built for particular types of material, but they can also be modified, so they’re able to slit different materials. Along with the roll specifications of the material, most manufacturers want machines that will slit specific materials when they’re choosing them. They also want to consider factors like how easy to use they are, their safety, floor space they would take up, and speed. A master roll is made to be as large as it can be because that’s cost-effective, which is why it then needs to be slit to the right width. 4. Winding Type Slitter rewinders can be characterized and categorized based on winding type, including: – Center winding: This is the most common method to rewind materials that might have different levels of thickness throughout the roll’s width. The material will go through a nip and anvil roll where it’s then slit using the right method. At that point, it’s rewound onto a core. This rewinding method is used for materials like woven items, foams, foils, films, and tapes. It’s useful for materials that could be sensitive to higher tension settings and compression. – Turret winding: The method is a variation of center winding. It’s an alternative that can help reduce machine downtime, so multiple shafts are used, and then the machine can keep slitting on an active shaft, while an operator or sometimes automated mechanisms will unload and then reset the finished shift. This method is meant to help reduce changeover times. It’s for consumer goods, paper items, tapes, and high-volume products. – Surface winding: Also referred to as drum surface winding, in this method, the rewinding materials are usually large in diameter. Non-wovens and paper are the applications of surface winding. – Center surface winding: in this method, there’s a combination of elements borrowing from traditional surface rewinding and also center winding. The applications for this method include materials that aren’t woven and are slit to a smaller width. As the diameter goes up, the rewinding center shaft will keep the tension. 5. How It Works There are three primary functions of a slitter rewinder which are performed in a fixed order. The process starts with the already rolled paper or material, and it has to be unwound so that it can go through the rewinder in one single layer. As it goes through the machine, it’s slit by one of many available cutting methods into strips of the right thickness. After the material is slit to its market-ready dimensions, it’s rewound into a roll that’s then sellable. The cutting can be done in different ways, primarily based on the type of material. The oldest type of cutting is known as score cutting. With score cutting, the materials between a dull blade and hard surface are cut. This is used for adhesives like tape, with a dry and sticky side. Another method is razor blade cutting, which tends to be the most cost-effective approach. This uses a blade positioned over the area where the sheet is fed. As the material goes through a drum or set of drums, it’s drawn against the blade. The method can’t be used for heavy items, rigid materials, or abrasive materials. Finally, there’s shear cutting which is the most accurate method, and it can be used with rigid, thicker, and heavier materials like laminates and foils. This uses two, typically rotating blades. The material is pulled between