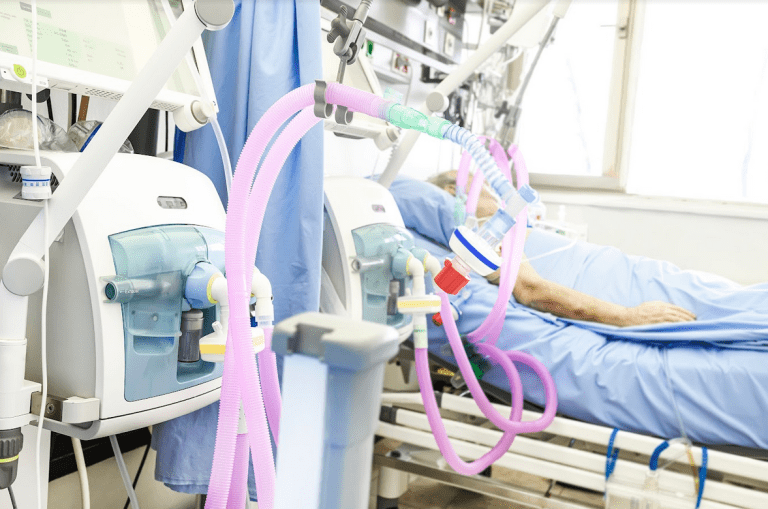

Healthcare technology has gained enormous accomplishments in recent years. Nowadays, medical care centres and hospitals are better equipped with amenities, medical tools, and equipment because of the advancement of technology. One technological product that plays a vital role in advancing quick patient recoveries is a medical vacuum pump. What Is A Medical Vacuum Pump? You might wonder: what is a medical vacuum pump? Medical vacuum pumps are devices that handle liquid and gaseous media for monitoring, diagnostics, speciality medicine, dental, critical care, dialysis, sterilization, ophthalmology, and therapeutic and surgical equipment. Aside from medical vacuum pumps, other pump solutions for healthcare include liquid pumps and swing piston compressors. Benefits Of Medical Vacuum Pumps Below are the benefits of medical vacuum pumps: Solid Clinical Diagnostic Results Medical vacuum pumps harness solid diagnostic results as medical professionals test different body fluids and tissues. Healthcare professionals, particularly medical technologists, utilise medical vacuum pumps to test samples quickly. For instance, diaphragm liquid pumps convey the same medium quantity while maintaining media purity and cleanliness over a certain period to obtain solid clinical diagnostic results. Meanwhile, most diagnostic instruments generate waste from probe washing, slide staining, and general draining. These instruments are necessary to pump the liquids to waste. Medical vacuum pumps, on the other hand, collect and remove via vacuum-over-liquid or direct pumping. In that way, medical diagnostic procedures yield more accurate results. Better Therapy And Treatment Results The most reliable medical vacuum devices can perform with high power density, quiet running operations, and superior gas tightness. With these characteristics, medical therapies and treatments harness better results. Medical vacuum pumps are effective across different therapy stages. They can be used in the preparation phase, instrument care, and on actual therapies, including radiation, wound care, and surgery. Medical vacuum pump applications include dental, cardiology, cosmetics, dialysis, Negative Pressure Wound Therapy (NPWT), and more. Medical vacuum pumps help control infection in patients undergoing NPWT. For ear, nose, and throat (ENT), medical vacuum pumps are used in ear flush applications and waste collection. They also help reduce the patient’s discomfort during ENT treatment procedures. And because medical vacuum pumps can handle manual tasks, healthcare professionals can focus on providing patient education and aftercare treatment. Doctors and nurses can monitor patients closely rather than worrying about inaccurate diagnostic and treatment results. Therefore, patients can recover quickly because of successful therapies and treatments. Excellent Patient Care Services Aside from diagnostics and treatment, medical vacuum pumps can positively change patient-healthcare worker relationships. This benefit can help promote better patient experience in medical training facilities, diagnostic centres, hospitals, and clinics. Medical vacuum pumps can help make the job of medical professionals easier and faster. With these devices, they don’t have to manually flush liquids, collect and dispose of liquid waste, and perform other manual pumping operations. Hence, healthcare workers can focus their time and attention on assessing and treating patients. On the other hand, patients feel more valued when a medical staff asks them how they’re doing. Such a scenario can help nurture a good relationship to boost cooperation in various medical procedures. Furthermore, patients gain more strength and confidence to undergo non-invasive and surgical procedures because they trust healthcare professionals. Risks Of Medical Vacuum Pumps Below are the risks of medical vacuum pumps and how to avoid them: Mechanical Hazards Medical vacuum pumps in laboratories can pose common mechanical hazards linked to their moving parts. However, most risks are preventable with proper medical vacuum pump operations. Nevertheless, operators must follow the manufacturer’s instructions for safe operations. In addition, they must ensure that medical vacuum pumps have belt guards. It’s also important to inspect cords and switches for defects. Chemical Hazards Aside from mechanical hazards, medical vacuum pumps can also pose chemical risks. For example, vacuum pumps contaminated with pump oil have volatile substances and gradually release into the laboratory. To avoid these devices becoming chemical hazards, it’s best to have them checked regularly. Moreover, proper maintenance and care are needed to keep them in good condition. Fire Hazards When medical vacuum pumps malfunction, they may pose a fire hazard. The pumps may overheat and catch fire nearby combustible or flammable materials. Hence, avoid placing medical vacuum pumps in enclosed, unventilated storage areas, and never operate them near flammable chemical containers. Conclusion Medical vacuum pumps play a crucial role in healthcare advancement. They’re used in diagnostics, therapies, and other medical procedures. Because of continuous research and development, medical vacuum pumps gain more features and benefits to serve patients with excellent quality of care.