In 1959, eight dairies in the Parmigiano Reggiano area founded the CCS Consorzio Caseifici Sociali. Over the years, the has business expanded to include the production and maturing of Parmigiano Reggiano.

In 1995, the Granterre Consortium was established, bringing together the entire Parmigiano Reggiano dairy chain, and then almost ten years later, in 2004, control of Parmareggio Spa was acquired. In 2019 Bonterre Spa, the holding company under which the control of Parmareggio Spa and Grandi Salumifici Italiani Spa (controlled by UNIBON) was established.

Then in 2021, Agriform Sca (leader in the production of Grana Padano PDO and the main Veneto PDOs such as Asiago, Piave, Montasio and Monte Veronese) merged with Parmareggio Spa to create the first Italian company in the world of PDO cheeses and cemented this new company as the leader in the Italian food industry.

New company requires fire safety upgrade

In 2021, the site at Sommacampagna required an upgrade of the fire detection system. Hochiki were the appointed manufacturers to supply the life safety system and devices due to their experience and expertise in the Italian fire safety market.

Within food production sites, the temperature and humidity inside the environment must be carefully controlled to comply with food hygiene laws, and because of this, these sites can be notoriously complex buildings to design and install fire safety systems for. The customer was looking for a high-performance fire detection system that would not be affected by these environmental factors, and most importantly avoid false alarms which can halt production and cost the company thousands of Euros for every minute the site is not fully operational.

The installation team also needed to pay particular attention to the installation of cables and piping. As a specialist in aged cheese production, it was imperative that the delicate work of the cheese wheels and the hot marking of the upper layer of the Parmesan rind was not affected during the installation project. One of the benefits to Hochiki products to this project was the ease of install and ease of use of the devices which had minimal impact on the business.

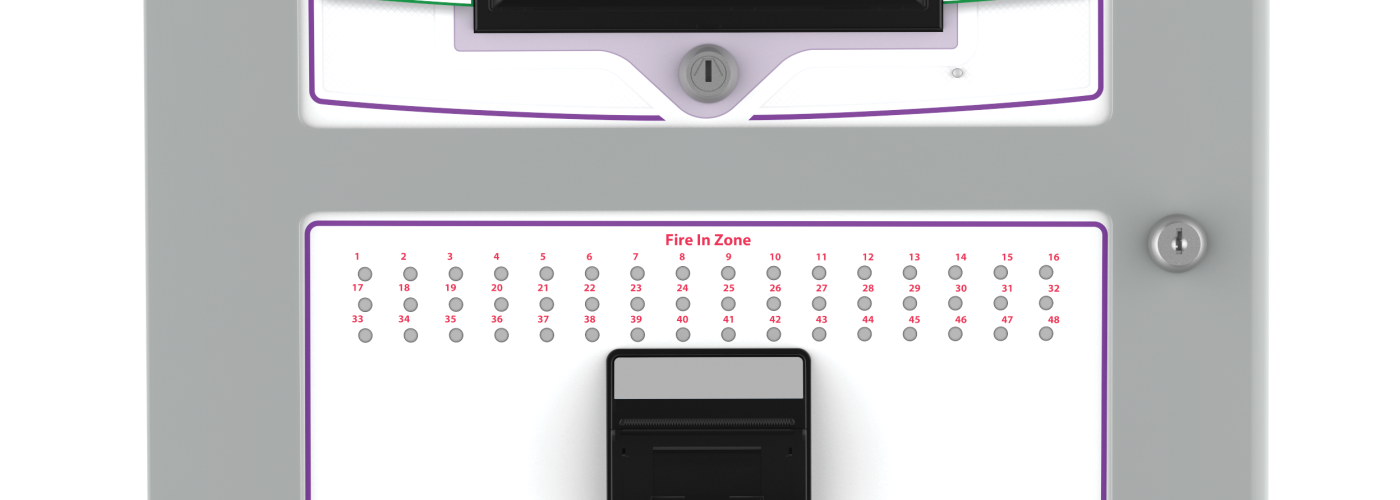

To meet the requirements of the project, the installer NET Technologies Srl chose Hochiki’s market leading system L@titude to be the brain of the life safety system. This innovative fire detection technology combines the very latest hardware and software to produce a control and indication system which is powerful and sophisticated, yet simple to use and understand via a graphical interface.

Mirko Corsini, project manager at Hochiki Italia, said: “The installer chose Hochiki’s L@titude panel together with our SPC-ET beam smoke detectors, which are characterised by low power consumption at rest and incorporate a sophisticated algorithm of automatic compensation to environmental changes.

The technical features of these products make them perfect for meeting the needs of this type of food processing environment. The flexibility of the Hochiki ESP protocol made it possible, through the CHQ-SZM2/SCI Zone Modules, to integrate conventional detectors (SPC-ET) as if they were addressable devices, without having to use auxiliary power supplies that would have required additional cables and batteries.”

Detectors with short circuit isolators were installed to ensure the system complied with the requirements of UNI EN 9795, which states that a short-circuit isolator must be installed for each room/compartment.

Intelligent Photoelectric Smoke detector with SCI incorporates Hochiki’s newest High Performance Chamber Technology. This detector removes the need to use Ionisation Smoke Sensors in many applications. This also allows the sensor threshold level to be increased, thereby improving the signal to noise ratio, and reducing the likelihood of false alarms.

Throughout the site Intelligent Loop-Powered Wall Sounder Beacons and Visual Alarm Devices were installed to ensure a fully compliant and state of the art fire safety system.

Commenting on the project, Fabrizio Bergamin, Technical Coordinator at the installer company NET Technologies srl, said: “We chose Hochiki devices and system because of the technical characteristics and reliability that this brand offers, as well as a wide range of products that fully meet market demands. Post commissioning of the project, the operating conditions envisaged in the design phase have been amply met. Over the course of the next year, there will be further implementations of the fire detection system at the Parmareggio production site, with distributed intelligence solutions or with several autonomous and networked L@titude control panels.

During the project we have had to deal with several technical design studios to solve various kinds of system problems; a fundamental role, together with the products they offer, is played by the Hochiki Italia technical support. They have responded competently to regulatory and design aspects, as well as proposed solutions for particular applications“.