The benefits of the partnership approach adopted by Siemens has been demonstrated in a project by EDSB to develop a fire detection and air sampling solution for a new warehouse operated by one of the UK’s most prominent retailers.

The facility in Warrington saw some 1,000 devices installed to protect the 81,570 m2 logistics warehouse area and its ancillary offices. Given the scale of the warehouse, which features high ceilings extending up to 43 metres at the highest point, the detection system needed to provide comprehensive coverage across the entire space. EDSB’s solution included air sampling with low-level test points and pipe runs exceding 200 metres, ensuring the system could accurately detect fires without interference from environmental conditions.

Before stepping foot on-site, EDSB’s in-house design team was tasked with creating for the project a compliant BS:5839 Part 1 system, aligned with the Category L1/P1 standards. Given the building’s complexity – including multiple mezzanine levels, cold storage areas, aerosol and battery storage, automated racking systems and comms rooms – the design required a range of detection technologies tailored to each area’s specific needs and environmental conditions.

Working with Siemens, after reviewing the 3D BIM models, specifications and fire strategy information, EDSB proposed a combination of air sampling systems, infrared linear beams, multi-sensor detectors, triple infrared flame detectors and gas suppression systems to ensure comprehensive coverage and compliance.

One of the main focuses of the brief was to develop a zero-false-alarm system, given the considerable costs associated with four-hour halts in production that could arise from unnecessary shutdowns. In consultation with Siemens, a solution was designed which saw a hybrid fire detection system capable of identifying environmental factors such as dust, smoke and exhaust fumes that could trigger false alarms.

Also central to the fire safety considerations was the high ceiling space which presented a particular challenge for traditional smoke detection: ‘stratification’ was identified as an issue whereby the smoke plume generated by a fire cools as it rises, often resulting in it having insufficient buoyancy to reach the roof and activate detectors. This was overcome by using Siemens ASD (Aspirating Smoke Detection), with the first stage of the installation process undertaken once the roof structure was in place. EDSB installed pipework and air sampling units in strategic positions across the warehouse to cover all areas, including the high ceiling zones. Following installation, the entire system was tested and calibrated to ensure optimal performance.

Another challenging factor in the project was the need to undertake phased works which operated in parallel with the warehouse construction. Several planning meetings took place to fully understand the site conditions and construction schedule. These meetings were crucial in ensuring that the installation would proceed smoothly alongside the building’s construction. Both the EDSB and Siemens teams, as well as the construction managers, worked together to

align on the scope, timeline and logistics of the project. Additionally, potential challenges such as access points and space constraints were identified and strategies were put in place to prevent delays later in the project.

Geoff Wain is a Senior Project Manager at EDSB. He comments – “This project has been a coordinated effort from the design stage through to installation and commissioning, primarily utilising in-house engineers. A dedicated site project engineer handled daily communication with our client to ensure that the phased

works were completed on time, delivering the project to the end client. The high standard of workmanship across the site is a testament to all those involved.”

Alistair Lyon was EDSB’s Install Leader on the project who said – “I believe what we have achieved is something that should be celebrated. This has been a long, challenging and complex installation and we have delivered an end product that we can all look back on and say we are proud to have been a part of.”

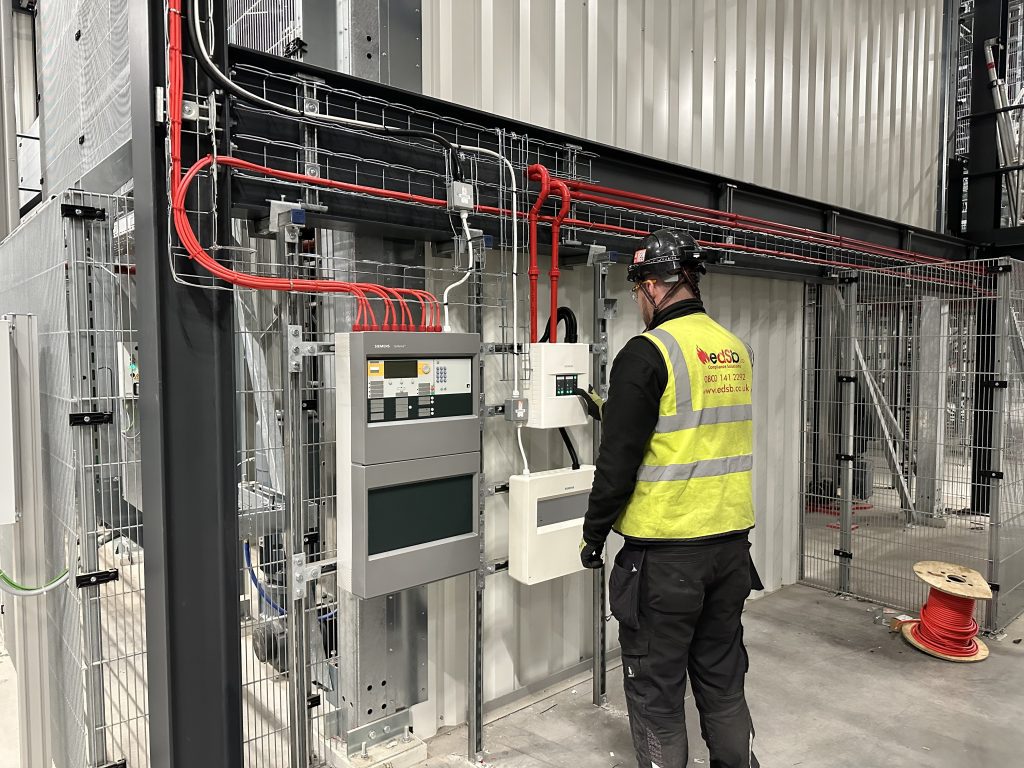

The facility has a Desigo CC building management head end which is able to display the information relating to the fire system and allows operators to visualise it. Desigo CC is also used on site to manage the HVAC systems, meaning all the building operation data can be viewed via a single interface. This leads to operational and energy efficiency savings. The on site computerised maintenance management system (CMMS) is also integrated into Desigo CC, with its open architecture allowing this integration to happen.

Siemens John Fennah added – “At Siemens we always strive to work closely with our partners and this application is an excellent example of how such an approach can achieve the best solution. By understanding and addressing the specific challenges presented by this warehouse, EDSB were able to match the appropriate technology with the different requirements, arriving at an integrated system which optimises fire safety while effectively managing the HVAC.”

In total, the site comprises nine networked Siemens fire panels, 34 Siemens aspirator panels, and more than 30 high-level Siemens beam detectors. The warehouse is equipped with 200 interfaces that control various shutdowns and integrate with third-party systems. Special care was taken to ensure the system provides comprehensive coverage.

For further information on Siemens Smart Infrastructure – Buildings

For further information on Siemens Smart Infrastructure, please see

www.siemens.com/smart-infrastructure

Building, Design & Construction Magazine | The Choice of Industry Professionals